Pure combustion high sodium coal two-stage medium temperature separation circulating fluidized bed saturated steam boiler

A circulating fluidized bed and steam boiler technology, which is applied in steam boilers, fluidized bed combustion equipment, steam generation and other directions, can solve the problems of boiler fault exhaust temperature, poor adaptability of high-sodium coal, high-temperature corrosion of sodium and potassium, etc. Achieve high ash concentration, improve self-cleaning ability and large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

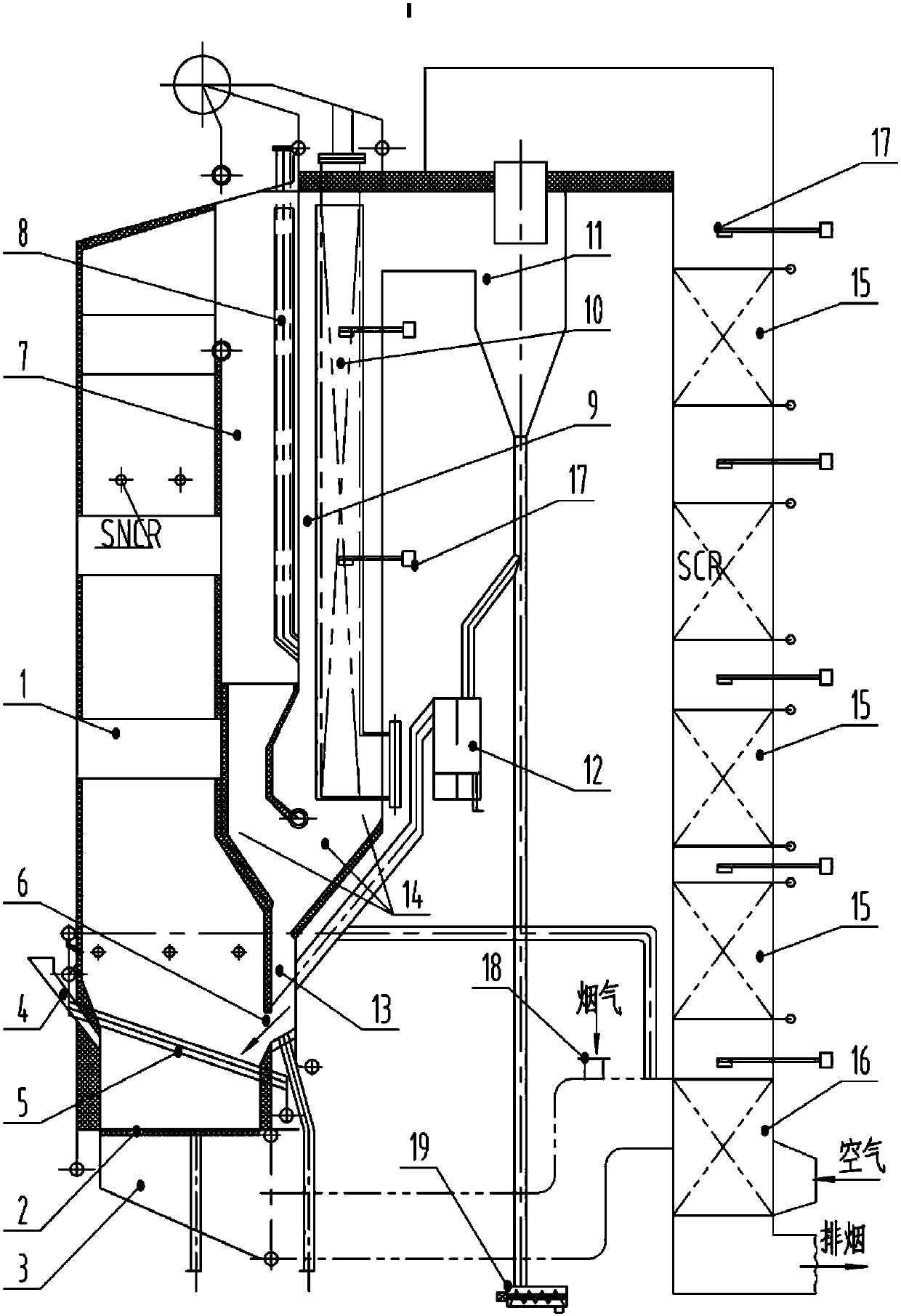

[0033] Embodiment 1: as attached figure 1 As shown, a two-stage middle-temperature separation circulating fluidized bed saturated steam boiler purely burning high-sodium coal, which includes a low-velocity bed furnace 1, and the lower part of the low-velocity bed furnace 1 communicates with the equal-pressure air chamber 3 through a small hood air distribution plate 2 , the lower part of the low-speed bed furnace 1 is provided with a feed pipe 4, a buried pipe 5, and a return port 6; the outlet of the low-speed bed furnace 1 turns downward and connects to the first water-cooling chamber 7, and the lower part of the first water-cooling chamber 7 gradually shrinks and becomes larger after turning downward , connect the primary accelerated sedimentation separator 14, the bottom of the primary accelerated sedimentation separator 14 is connected with a settling tank 13, the bottom of the sedimentation tank 13 is connected with the return port 6; the primary accelerated sedimentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com