Detection method for lithium-ion-battery lithium separating

A lithium-ion battery and detection method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of affecting battery cycle and safety performance, greatly affecting accuracy, and large energy consumption, so as to shorten the detection and evaluation time and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] The lithium-ion power battery to be tested is a sealed battery that has been pre-formed for 8 hours. The SOC of the pre-formation is 20%. The positive electrode material of the power battery is lithium iron phosphate, and the charging environment temperature is 25°C.

[0021] The lithium-ion power battery to be tested is charged for the first time by the following methods: ①Stand aside for 5min; ②0.5C constant current charging, cut-off voltage 3.6V; ③Stay for 5min; C;

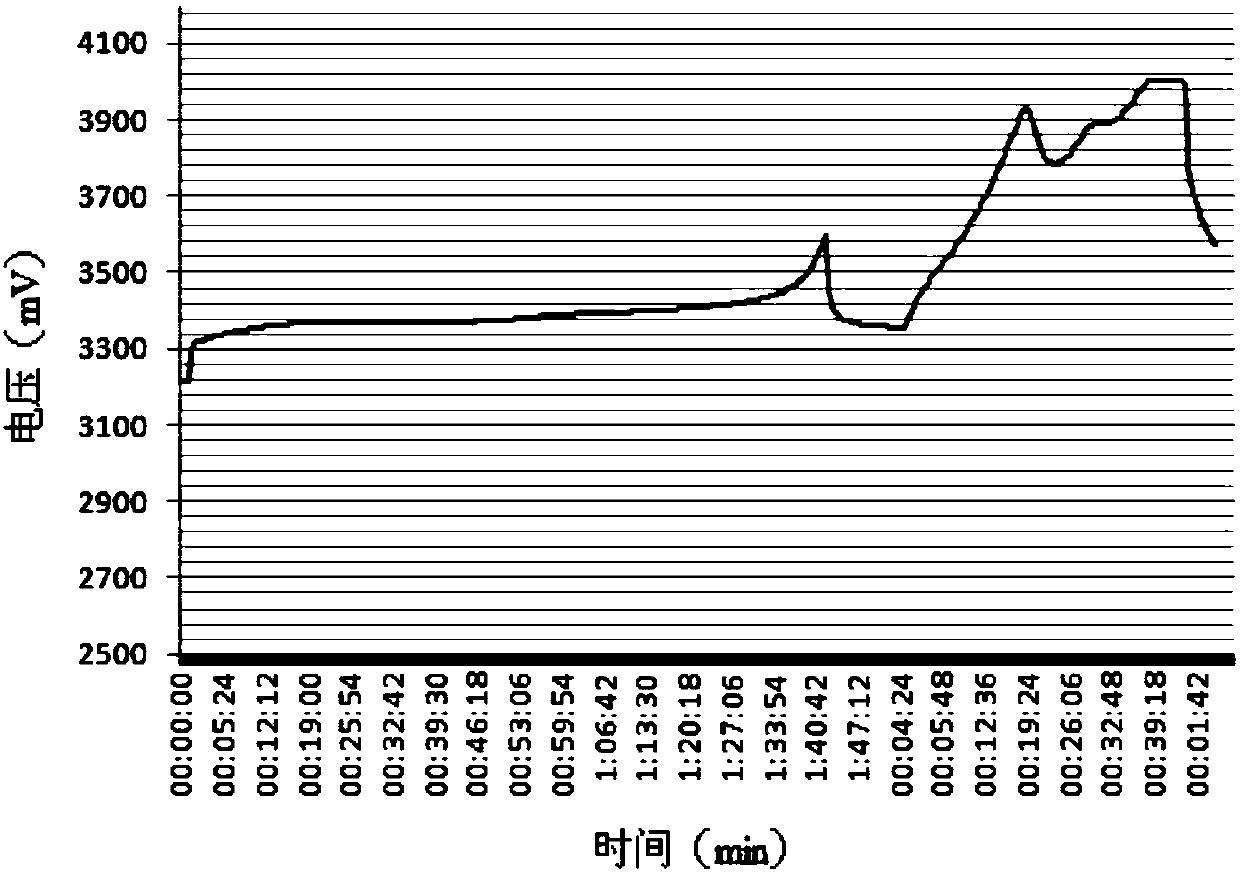

[0022] The voltage monitoring of the equipment shows that the voltage of the lithium-ion power to be tested is abnormal in the constant current stage during the small current constant-current constant-voltage charging process. The analysis of real-time collected data reveals that the lithium-ion power to be tested is in the 0.15C constant-current charging process, 19min After the voltage reached 3.927V, the potential attenuation began to appear, and the duration was 5 minutes. It was preliminarily determ...

Embodiment approach 2

[0025] The lithium-ion power battery used was preformed and then sealed for 5 hours. The preformed SOC was 25%. The positive electrode material of the power battery was lithium iron phosphate, and the charging environment temperature was 25°C.

[0026] The lithium-ion power battery to be tested is charged for the first time by the following methods: ①Stand aside for 3 minutes; ②0.4C constant current charging, cut-off voltage 3.5V; ③Stay for 3 minutes; C;

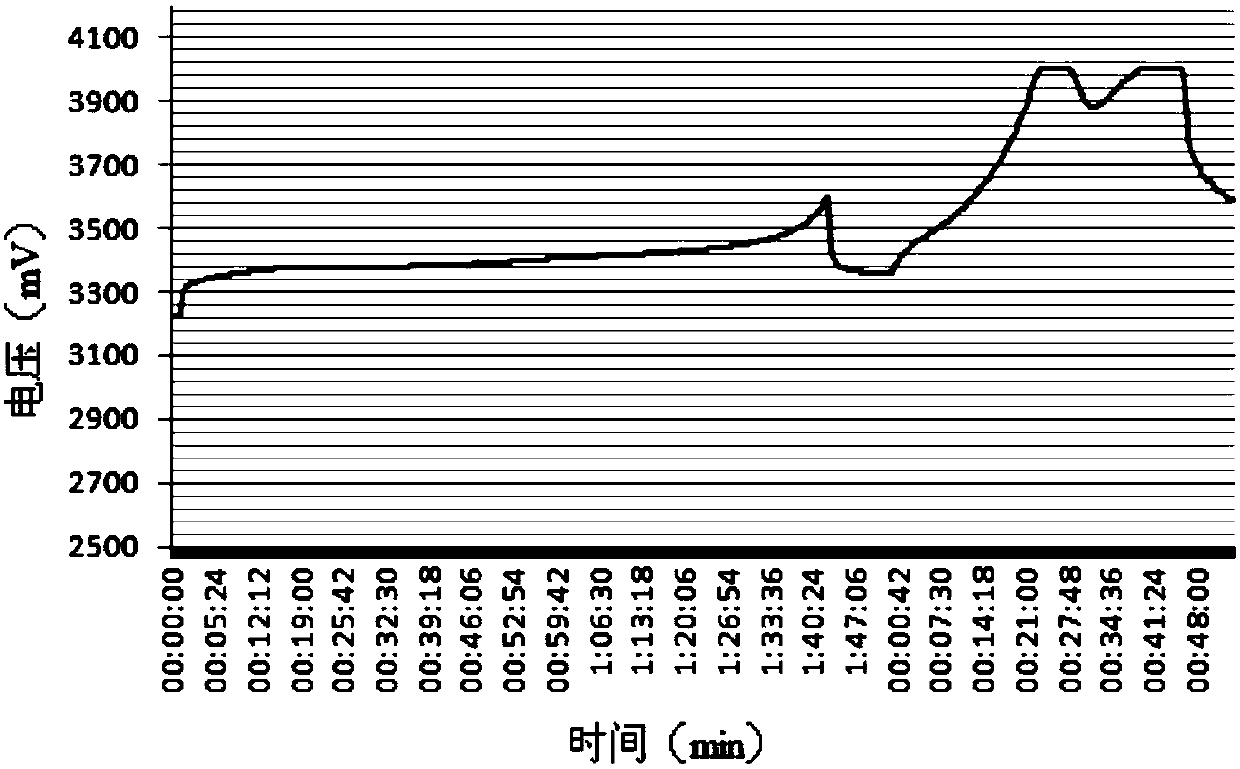

[0027] The device voltage monitoring found that the voltage of the lithium-ion power battery under test was abnormal in the constant-voltage stage during the small-current constant-current constant-voltage charging process. Analysis of the real-time collected data found that the lithium-ion power battery under test appeared in the constant-voltage stage when the voltage reached 4.0V. The potential decay lasts for 4 minutes, and it is preliminarily determined that the lithium-ion power battery to be tested is decomposed of li...

Embodiment approach 3

[0030] The lithium-ion power battery used is a sealed battery after pre-formation and charging, the pre-formation SOC is 30%, the positive electrode material of the power battery is lithium iron phosphate, and the charging environment temperature is 25°C.

[0031] The lithium-ion power battery to be tested is charged for the first time by the following methods: ①Stand aside for 4min; ②0.7C constant current charging, cut-off voltage 3.7V; ③Stay for 4min; C;

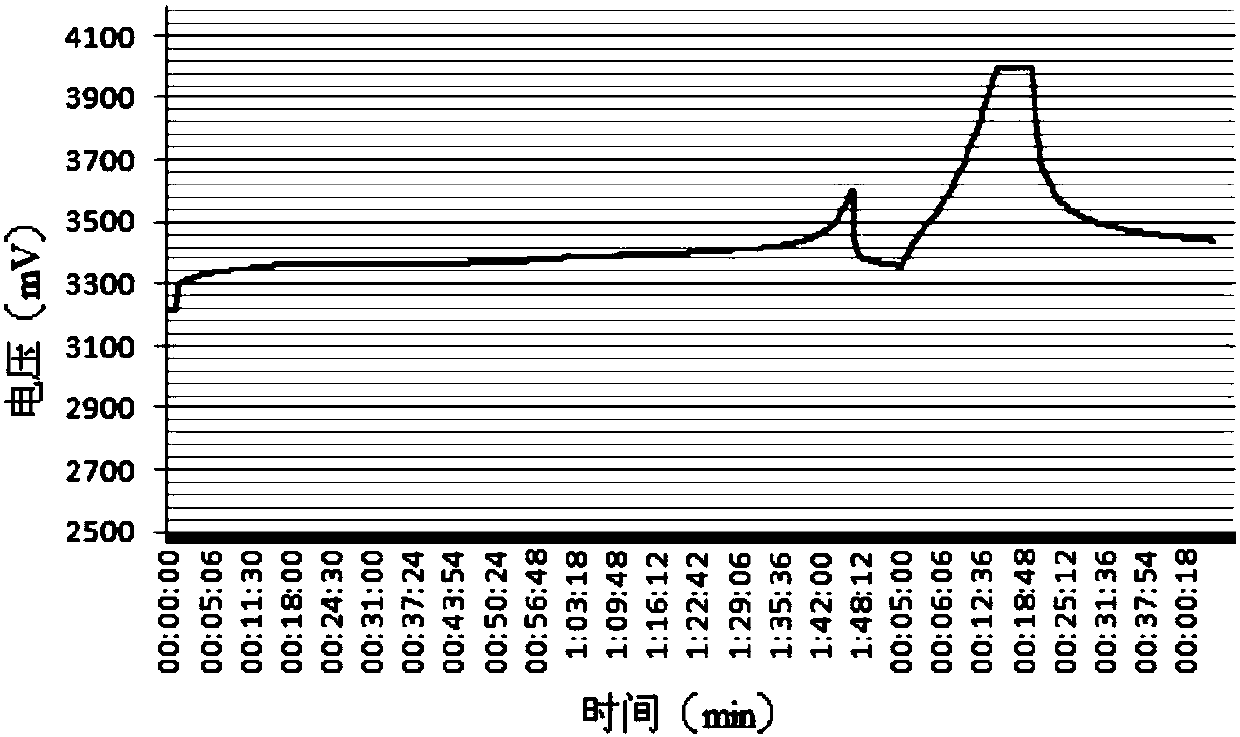

[0032] The equipment voltage monitors that the lithium-ion power battery under test is not found to be abnormal in the small current constant-current constant-voltage charging process, and it is determined that the lithium-ion power battery under test is a normal battery.

[0033] Verification: The lithium-ion power battery to be tested was disassembled, and it was found that the lithium-ion power battery to be tested did not decompose lithium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com