LED lamp bead with characteristic of 360-degree light emitting and production process thereof

A technology of LED lamp beads and LED chips, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problem of not being able to achieve 360 degrees, and achieve the effects of reducing light energy loss, high lighting efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

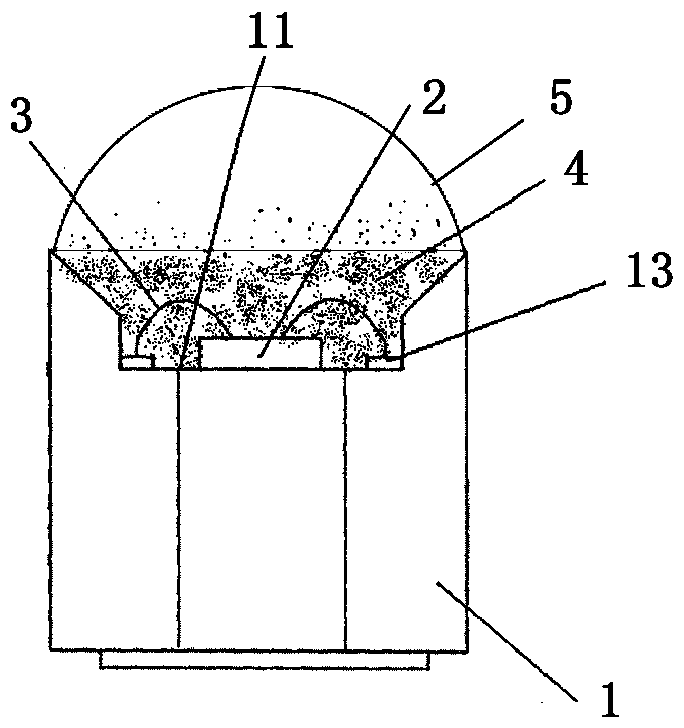

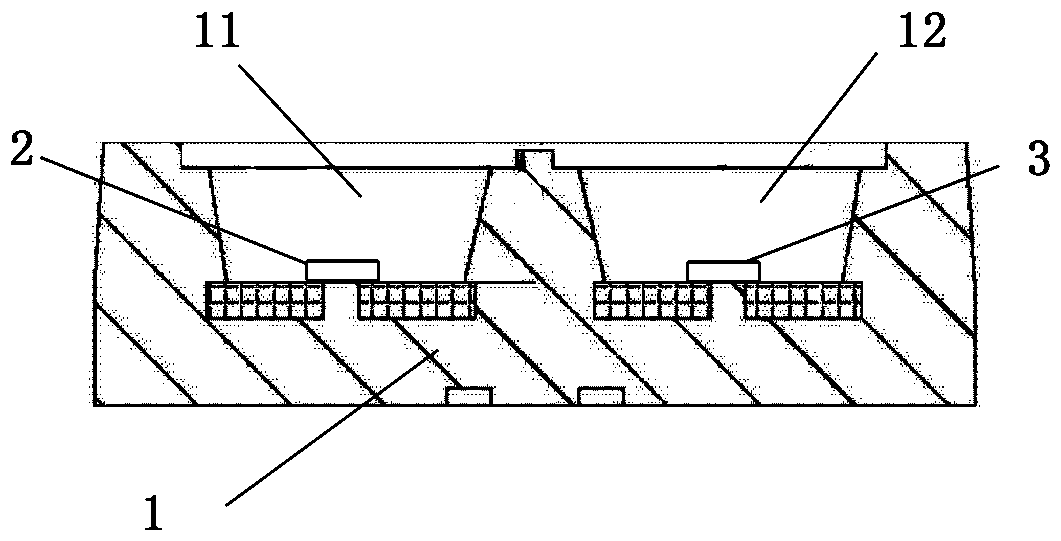

[0041] see Figure 1-2 As shown, the present invention relates to a 360-degree luminous LED lamp bead. The electrodeless double-chip LED lamp bead 100 includes a transparent bracket 1, and the top surface of the transparent bracket 1 is recessed with a reflective cup. The reflective cup includes a first A crystal cup 11 and a second crystal cup 12, the first crystal cup 11 and the second crystal cup 12 are respectively provided with a forward LED chip 2 and a reverse LED chip 3, and the transparent support 1 is provided with a support electrode, The electrodes of the forward LED chip 2 and the reverse LED chip 3 are respectively connected to the bracket electrodes on the transparent bracket 1 through gold wires 3, and the forward LED chip 2 and the reverse LED chip 3 are connected in parallel, A transparent epoxy resin and silica gel mixed layer 5 is encapsulated on the LED chip 2 , the reverse LED chip 3 and the gold wire 4 .

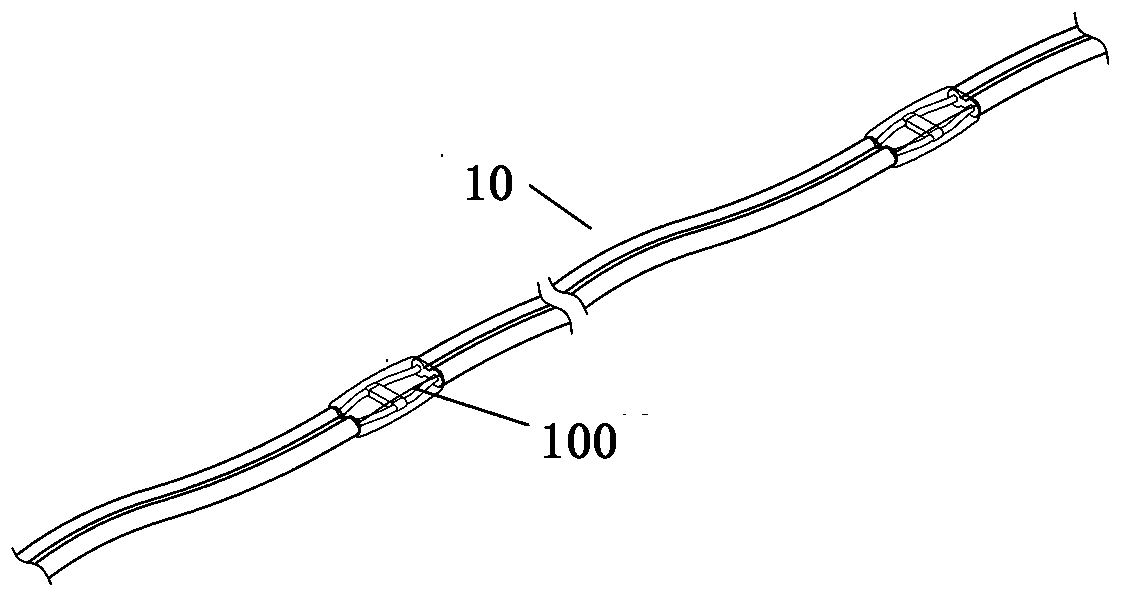

[0042] see Figure 3-6 The LED light strip 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com