A composite solid-state electrolyte with a multi-level structure for a wide potential window for lithium batteries

A solid electrolyte, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as affecting battery performance, low ionic conductivity, and inhibiting application of interface compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] PVCA-PPC-PEO three-layer composite solid electrolyte

[0045] Dissolve PVCA and LiDFOB with a molecular weight of 150,000 in DMF, the mass ratio of PVCA and LiDFOB is 5:1, and the concentration of PVCA in DMF is 2 g mL -1 ; Dissolve PPC and LiDFOB with a molecular weight of 300,000 in acetonitrile, the mass ratio of PPC and LiDFOB is 5:1, and the concentration of PPC in acetonitrile is 4 g mL -1 ; Dissolve PEO and LiDFOB with a molecular weight of 5 million in acetonitrile, the mass ratio of PEO and LiDFOB is 5:1, and the concentration of PEO in acetonitrile is 2 g mL -1 .

[0046] Scrape the PVCA solution on the glass plate with a 75 μm spatula; 60 o C dry for 6 hours, scrape the PPC solution on the PVCA film with a 400 μm spatula; 60 o C dry for 6 hours, scrape the PEO solution on the PPC film with a 250 μm spatula; place the electrolyte at 60 o C vacuum oven for 12 hours to obtain a PVCA-PPC-PEO three-layer composite polymer electrolyte with a thickness of 200 μm.

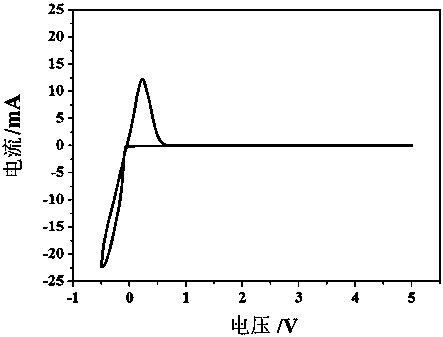

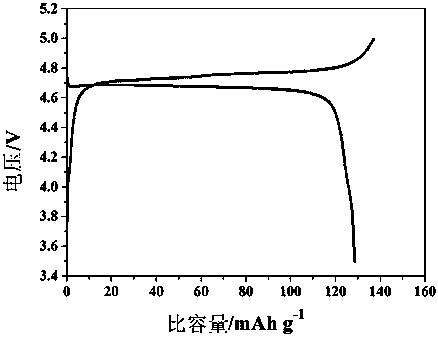

[0047] T...

Embodiment 2

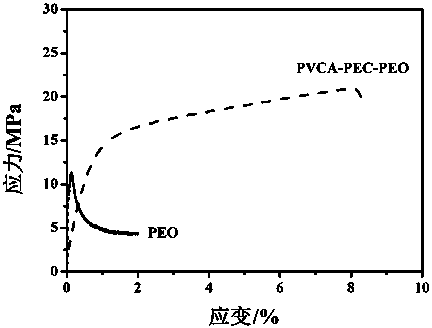

[0049] PVCA-PEC-PEO three-layer composite solid electrolyte

[0050] Dissolve PVCA and LiTFSI with a molecular weight of 150,000 in DMF, the mass ratio of PVCA and LiTFSI is 5:1, and the concentration of PVCA in DMF is 2 g mL -1 ; Dissolve PEC and LiTFSI with a molecular weight of 300,000 in acetonitrile, the mass ratio of PEC and LiTFSI is 2:1, and the concentration of PEC in acetonitrile is 4 g mL -1 ; Dissolve PEO and LiTFSI with a molecular weight of 1 million in acetonitrile, the mass ratio of PEO and LiTFSI is 5:1, and the concentration of PEO in acetonitrile is 2 g mL -1 .

[0051] Scrape the PVCA solution on the glass plate with a 50 μm spatula; 60 o C dry for 6 hours, scrape the PEC solution on the PVCA film with a 600 μm spatula; 60 o C dry for 6 hours, scrape the PEO solution on the PEC membrane with a 400 μm spatula; place the electrolyte at 60 o C vacuum oven for 12 hours to obtain a PVCA-PEC-PEO three-layer composite polymer electrolyte with a thickness of 300 μm.

[005...

Embodiment 3

[0054] PMMA-PPC-PPO three-layer composite solid electrolyte

[0055] Dissolve PMMA and LiTFSI with a molecular weight of 300,000 in DMF, the mass ratio of PMMA and LiTFSI is 5:1, and the concentration of base PMMA in DMF is 0.5 g mL -1 ; Dissolve PPC and LiTFSI with a molecular weight of 300,000 in acetonitrile, the mass ratio of PPC and LiTFSI is 5:1, and the concentration of PPC in acetonitrile is 4 g mL -1 ; Dissolve PPO and LiTFSI with a molecular weight of 300,000 in acetonitrile, the mass ratio of PPO and LiTFSI is 8:1, and the concentration of PPO in acetonitrile is 1 g mL -1 .

[0056] Scrape the PMMA solution on the glass plate with a 20 μm spatula; 60 o C dry for 6 hours, scrape the PPC solution on the PMMA film with a 100 μm spatula; 60 o C dry for 6 hours, scrape the PPO solution on the PPC film with a 100 μm spatula; place the electrolyte at 60 o C vacuum oven for 12 hours to obtain a PMMA-PPC-PPO three-layer composite polymer electrolyte with a thickness of 80 μm.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com