Integrated PCBN round rod-shaped cutting tool and manufacturing method thereof

A technology for cutting tools and round rods, applied in the field of integral PCBN round rod-shaped cutting tools and its preparation, can solve the problems of increasing equipment costs, inability to cut three-dimensional or shaped PCBN brazing sheets, and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

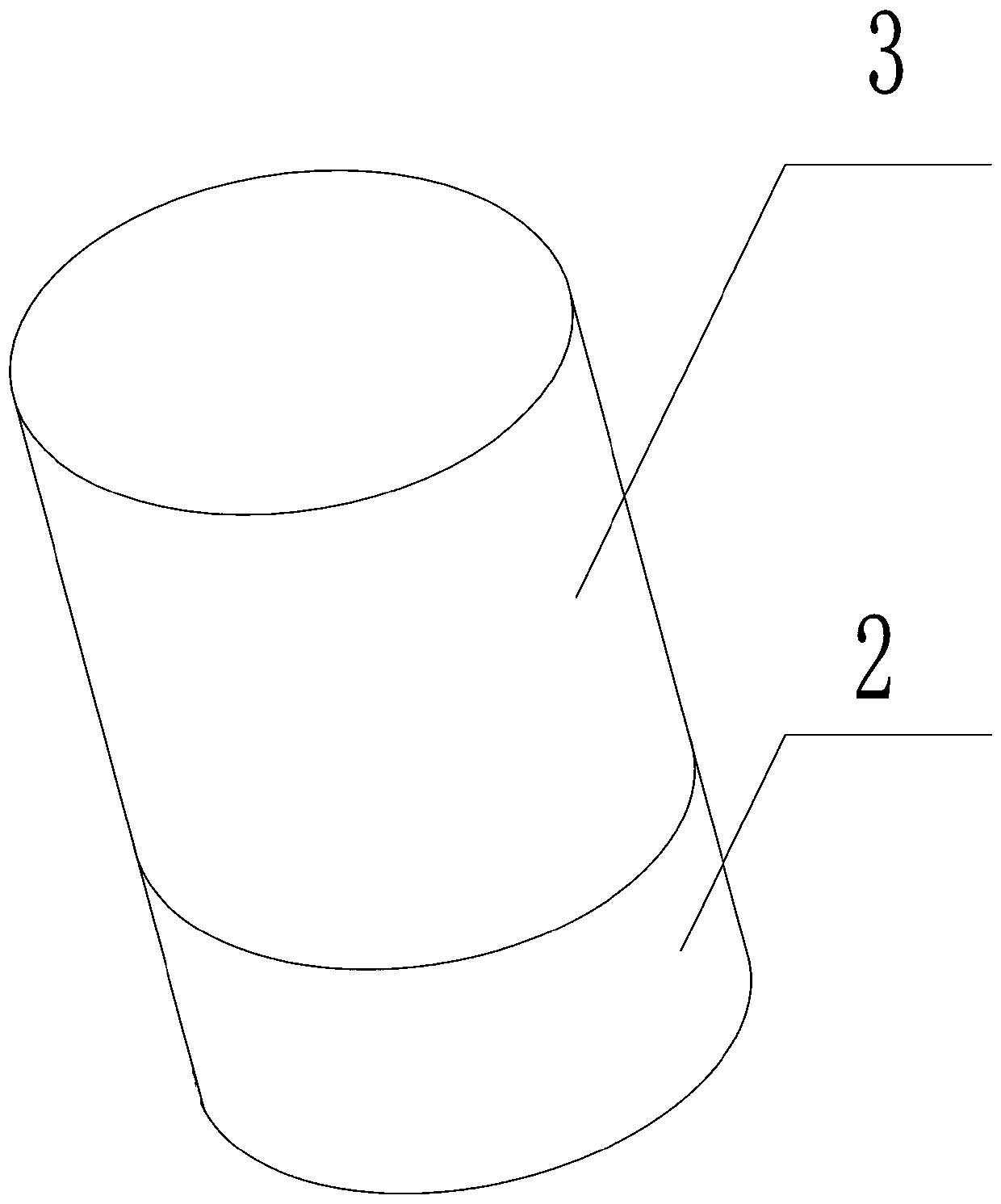

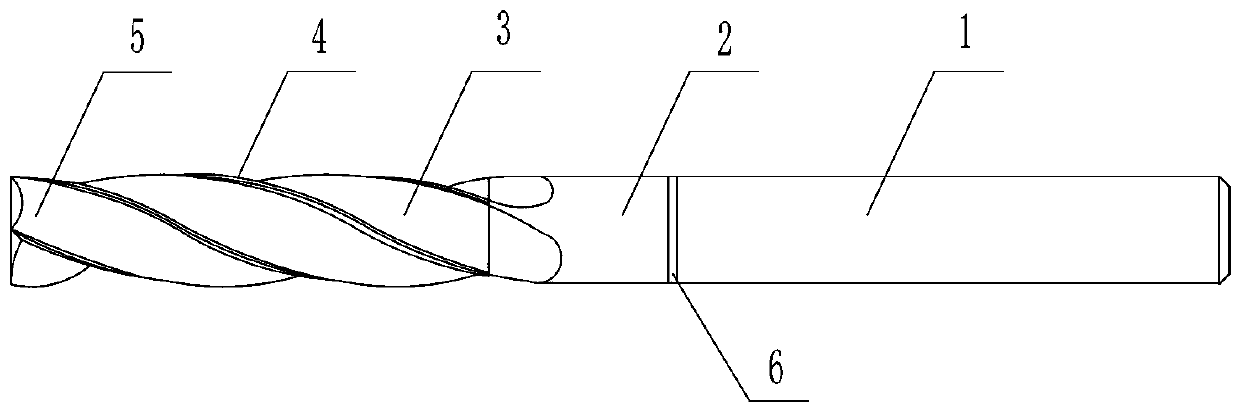

[0028] The present embodiment provides a kind of integral PCBN circular rod-shaped cutting tool, such as figure 1 and figure 2 As shown, it includes a carbide handle 1 and an integral PCBN circular rod-shaped cutter head welded on the carbide handle 1;

[0029] The overall PCBN circular rod-shaped cutter head includes a cemented carbide substrate layer 2 and a polycrystalline cubic boron nitride layer 3 arranged on one side of the cemented carbide substrate layer 2, and the other side of the cemented carbide substrate layer 2 One side is welded with the hard alloy handle 1, and a layer of weld seam 6 is formed between the two.

[0030] Specifically, such as figure 2 As shown, the overall PCBN circular rod-shaped cutter head is provided with a chip removal groove 5, and the chip removal groove 5 extends from the polycrystalline cubic boron nitride layer 3 to the middle of the cemented carbide substrate layer 2 , the edges of the flutes located on the polycrystalline cubic ...

Embodiment 2

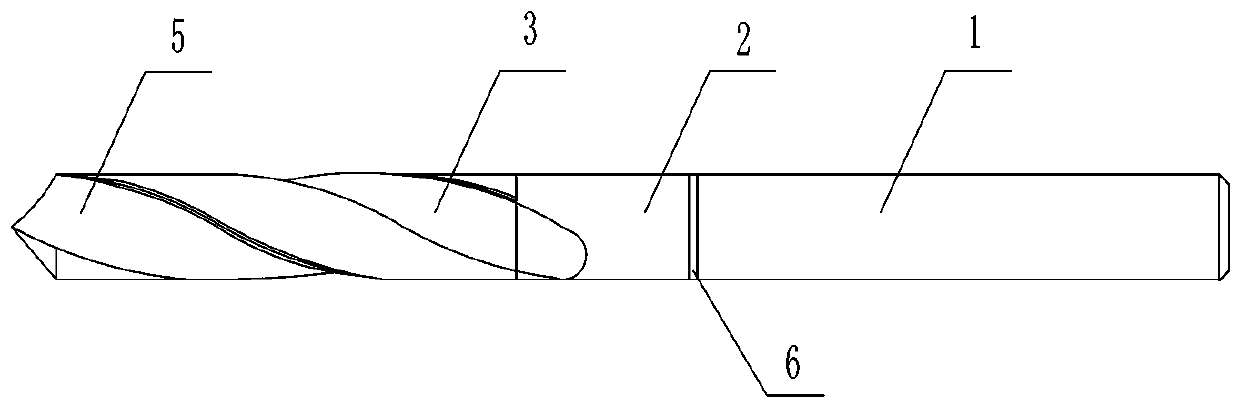

[0040] The present embodiment provides a kind of integral PCBN circular rod-shaped cutting tool, such as figure 1 and image 3 As shown, it includes a carbide handle 1 and an integral PCBN circular rod-shaped cutter head welded on the carbide handle 1;

[0041] The overall PCBN circular rod-shaped cutter head includes a cemented carbide substrate layer 2 and a polycrystalline cubic boron nitride layer 3 arranged on one side of the cemented carbide substrate layer 2, and the other side of the cemented carbide substrate layer 2 One side is welded with the hard alloy handle 1;

[0042] The overall PCBN circular rod-shaped cutter head is provided with a chip removal groove 5, and the chip removal groove 5 extends from the polycrystalline cubic boron nitride layer 3 to the middle part of the hard alloy substrate layer 2, and is located at the The edge of the flute on the polycrystalline cubic boron nitride layer 3 forms a cutting edge. The chip removal groove 5 is a spiral chip ...

Embodiment 3

[0049] This embodiment provides an integral PCBN circular rod-shaped cutting tool, the specific structure is roughly the same as that in Embodiment 2, the difference is that:

[0050] In this embodiment, the outer peripheral surface of the polycrystalline cubic boron nitride layer is also provided with a cutting cone and a calibration thread to form an integral PCBN circular rod-shaped tap.

[0051] This embodiment also provides a method for preparing the above-mentioned integral PCBN circular rod-shaped cutting tool, the specific steps are roughly the same as those in Embodiment 2, the difference is that:

[0052] In this embodiment, the step of preparing the overall PCBN circular rod-shaped cutter head also includes grinding the cutting cone and the calibration thread on the outer peripheral surface of the polycrystalline cubic boron nitride layer by using the vitrified bond diamond grinding wheel. step by step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com