Method for preparing silica modified barium sulfate powder

A technology of silicon dioxide, barium sulfate powder, applied in chemical instruments and methods, calcium/strontium/barium sulfate, inorganic chemistry, etc., can solve the problems of complex process, uneven dispersion, organic matter modification, etc. Simple, simple process, reducing the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

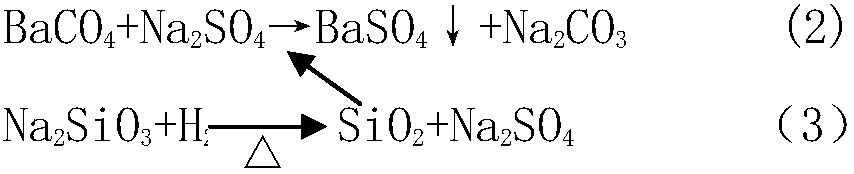

Method used

Image

Examples

Embodiment 1

[0023] (1) Prepare a barium sulfide solution with a concentration of 15wt%, add it to a sodium carbonate solution with a concentration of 25wt% according to a molar ratio of 1:1.5, and react with high-shear stirring at a speed of 8000r / min at 30°C for 4 hours;

[0024] (2) After step (1) is filtered and washed, according to the molar ratio of sodium sulfate and barium sulfide is 1:1.5, the filter cake is added to a concentration of 25wt% sodium sulfate solution to carry out a high-shear stirring reaction at a speed of 8000r / min. , the reaction temperature is 30°C, and the reaction time is 8 hours;

[0025] (3) After completing step (2), add sodium silicate with a concentration of 15wt% in step (2), the addition amount is 10% of the molar weight of barium sulfide, and at the same time add 0.8 moL -1 The sulfuric acid solution was stirred and reacted at a speed of 8000r / min for 2 hours, filtered, washed with water, and dried at 200°C to obtain ultrafine silica-modified barium s...

Embodiment 2

[0027] (1) Prepare a barium sulfide solution with a concentration of 0.1wt%, add it to a sodium carbonate solution with a concentration of 1wt% according to a molar ratio of 1:1.2, and react with high-shear stirring at a speed of 500r / min at 20°C for 0.5 hours;

[0028] (2) After step (1) is filtered and washed, according to the molar ratio of sodium sulfate and barium sulfide is 1:1.2, the filter cake is added to a concentration of 1wt% sodium sulfate solution to carry out a high-shear stirring reaction at a speed of 500r / min. , the reaction temperature is 20°C, and the reaction time is 0.5 hours;

[0029] (3) After completing step (2), add sodium silicate with a concentration of 10wt% in step (2), the addition amount is 0.1% of the molar weight of barium sulfide, and at the same time add 0.2% sodium silicate with a molar ratio of 1.1:1 moL -1 Sulfuric acid solution, continue to react with high-shear stirring at a speed of 500r / min for 1 hour, filter, wash with water, and dr...

Embodiment 3

[0031] (1) Prepare a barium sulfide solution with a concentration of 10wt%, add it to a sodium carbonate solution with a concentration of 15wt% according to a molar ratio of 1:1.3, and react with high-shear stirring at a speed of 3000r / min at 65°C for 2 hours;

[0032] (2) After step (1) is filtered and washed, according to the molar ratio of sodium sulfate and barium sulfide is 1:1.3, the filter cake is added to a concentration of 15wt% sodium sulfate solution to carry out a high-shear stirring reaction at a speed of 3000r / min. , the reaction temperature is 65°C, and the reaction time is 2 hours;

[0033] (3) After completing step (2), add sodium silicate with a concentration of 12wt% in step (2), and the addition amount is 5% of the molar weight of barium sulfide, and at the same time add sodium silicate with a molar ratio of 1.1:1 0.4molL -1 Sulfuric acid solution, continue to react at a speed of 3000r / min under high shear for 1.5 hours, filter, wash with water, and dry at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com