An integrated electric power-assisted braking system

An electric power assist and braking system technology, applied in electric braking systems, brakes, electric vehicles, etc., can solve the problems of stuck, excessive mechanical resistance, high production cost, etc., to reduce the axial size and improve braking The effect of performance and convenient installation in real vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

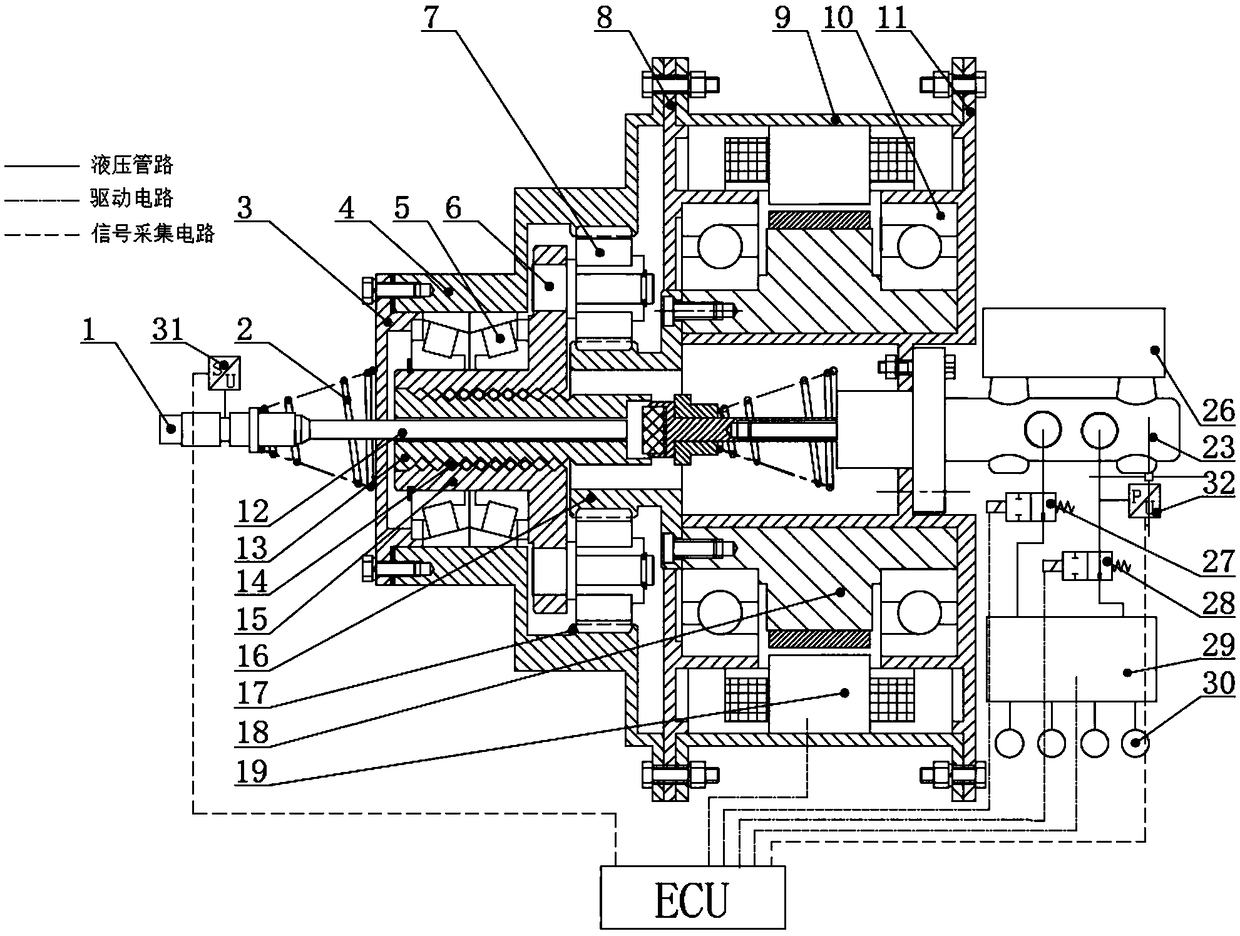

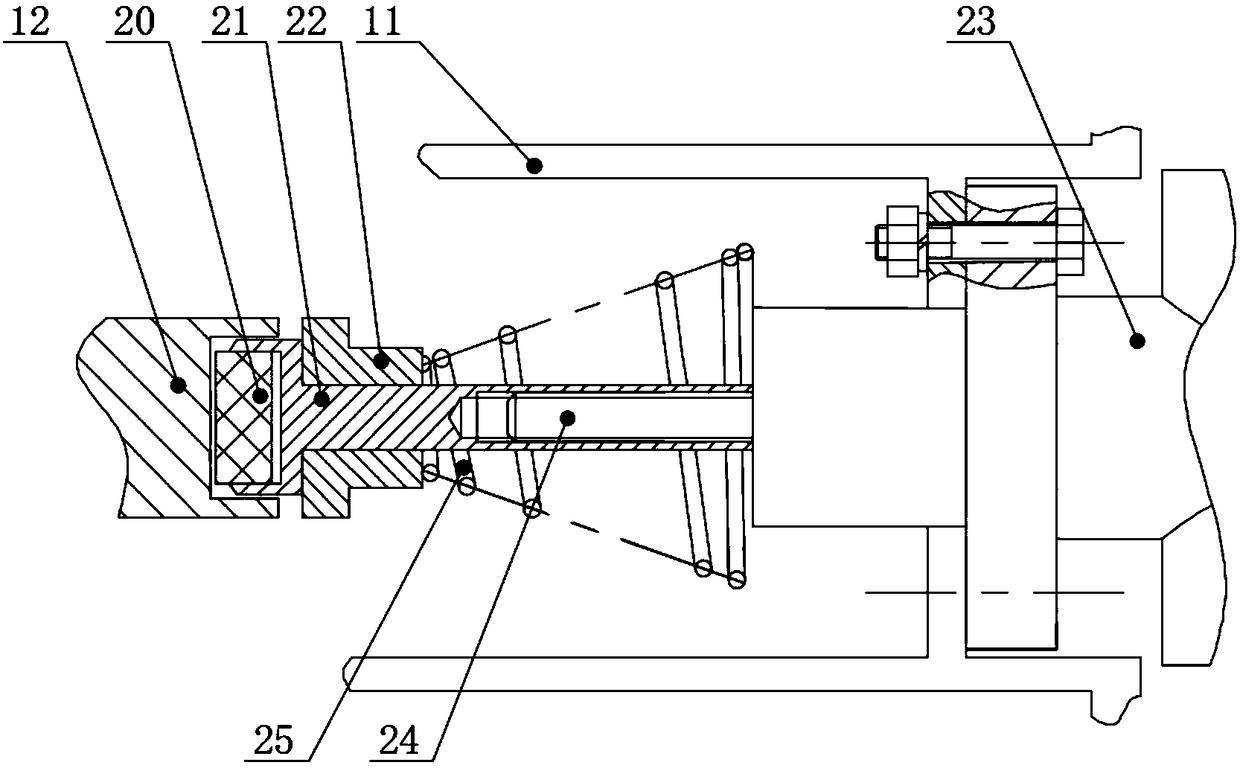

[0031] The present invention is described below in conjunction with accompanying drawing:

[0032] refer to figure 1 , an integrated electric power-assisted braking system according to the present invention includes a motor housing 9 , a planetary gear housing 4 and a middle end cover 8 . Take the direction of the driver's braking force input as the front. The rear end face of the planetary gear housing 4, the middle end cover 8, and the front end face of the motor housing 9 are evenly distributed with four threaded holes of the same specification. The front end faces of the machine housing 9 are connected by bolts and nuts. The front end of the planetary gear housing 4 is covered by a front end cover 3, and the two are connected by screws.

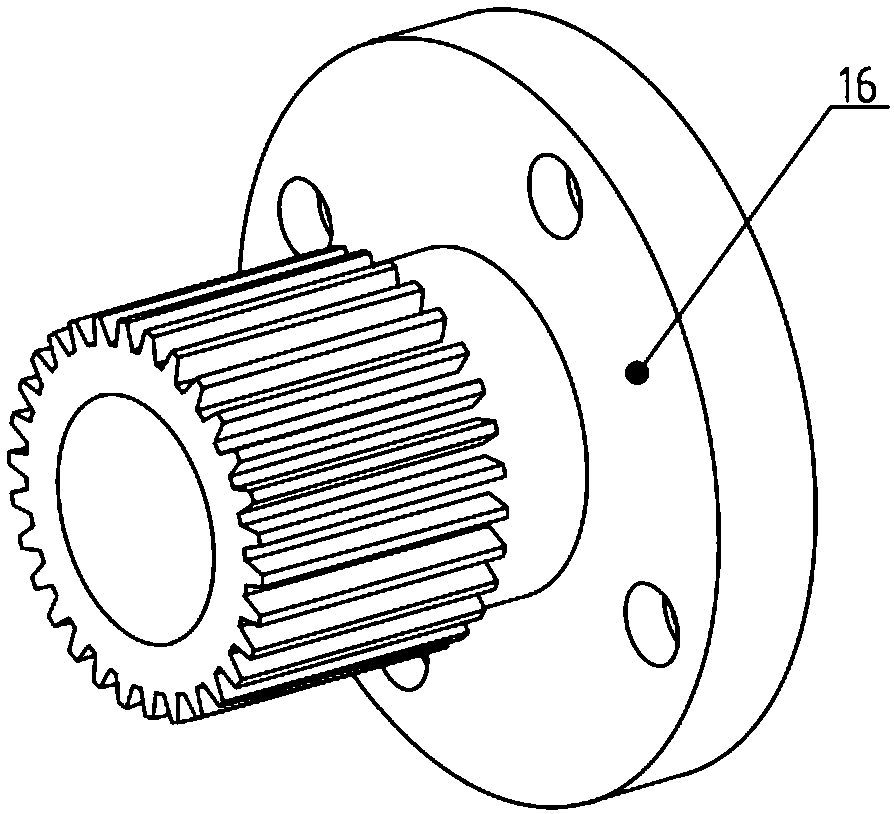

[0033] refer to figure 1 , the motor housing 9 is provided with a motor, the motor includes a motor stator 19 and a motor rotor 18, the front section of a hollow stepped shaft-shaped rear end cover 11 is a small journal section, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com