Blue mirror for automobile rearview mirror and preparation method thereof

A technology of automobile rearview mirror and film layer, applied in vehicle parts, ion implantation plating, coating and other directions, can solve the problem of inability to effectively achieve anti-glare and other problems, reduce the interference of strong light on the driver's line of sight, and achieve environmental durability. The effect of improving sexuality and reducing the interference of sight lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Embodiments of the present invention also provide a method for preparing a blue mirror for an automobile rearview mirror, comprising the steps of:

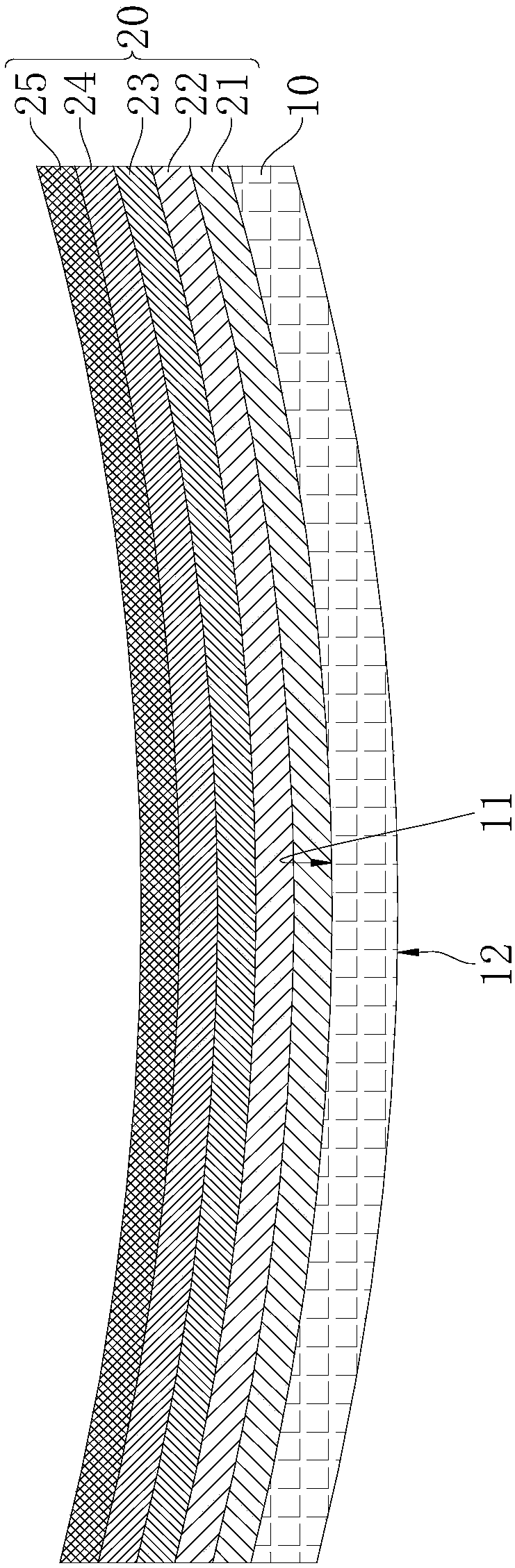

[0046] S1: Obtain the desired hot-bent glass substrate 10, the hot-bend glass substrate 10 includes opposite concave surfaces 11 and convex surfaces 12;

[0047] S2: Coating a first high refractive index film layer 21 on the concave surface 11 of the hot-bending glass substrate 10;

[0048] S3: Coating a first low refractive index film layer 22 on the first high refractive index film layer 21;

[0049] S4: Coating a second high refractive index film layer 23 on the first low refractive index film layer 22;

[0050] S5: Coating a second low refractive index film layer 24 on the second high refractive index film layer 23;

[0051] S6: Plating a metal film layer 25 on the second low refractive index film layer 24 .

[0052] Specifically, the blue mirror for an automobile rearview mirror prepared by the method for preparing ...

Embodiment approach

[0060] 1.85mm plain white float glass is used as the hot-bent glass substrate 10, and a magnetron sputtering coating machine is used. Niobium pentoxide film layer was plated by medium frequency AC magnetron sputtering, Ar gas volume was 200sccm, O 2 The gas volume is 100sccm, and the sputtering pressure is guaranteed to be 2.5×10 -3 , the niobium target used is a twin target, and the niobium pentoxide film is plated on the hot-curved glass substrate 10 by medium-frequency AC magnetron sputtering, and the thickness of the film plated by this process is about 32nm. Subsequently, a 60nm silicon dioxide film layer is plated on the niobium pentoxide film layer, and the preferred Ar gas volume is 200 sccm, O 2 The gas volume control adopts PID control, the control voltage is 380V, and the preferred sputtering gas pressure is 2.5×10 -3 , the target used is a twin target. Then adopt the intermediate frequency AC magnetron sputtering method to plate the niobium pentoxide film layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com