Intelligent method for moisture retention spraying curing of concrete through coupling of temperature, humidity and wind speed

A technology for concrete and concrete surfaces, which is applied in hydropower stations, hydroelectric power generation, construction, etc., and can solve problems such as backward technology, large water consumption, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

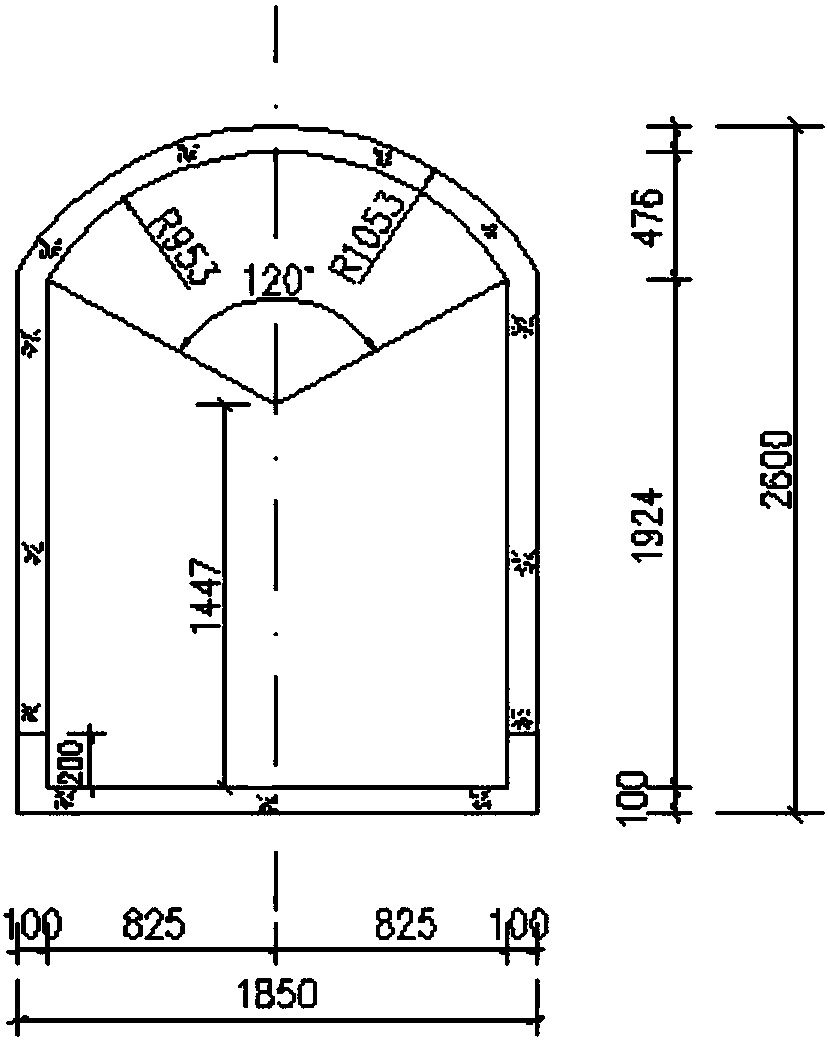

[0052] Intelligent method of coupling temperature, humidity and wind for concrete moisturizing and spraying maintenance

[0053] Such as image 3 As shown, the intelligent method for coupling temperature, humidity and wind of concrete moisturizing spray curing provided by this embodiment 1 includes the following steps:

[0054] Step 1. Arrange the concrete surface protection layer 1, select and arrange the sprinkler device.

[0055] Here, the concrete surface protection layer is: a thin layer of soft material that is laid on the concrete curing surface and has thermal insulation and moisturizing effects. It can be geotextiles, linen, straw curtains, plastic films, and other soft materials. It is recommended to cover horizontal or inclined surfaces with geotextiles, linen, straw curtains, etc. in summer, focusing on moisturizing. In winter, cover them with plastic film after spraying and then cover them with geotextiles, linen, straw curtains, etc. to keep warm and moisturize...

Embodiment 2

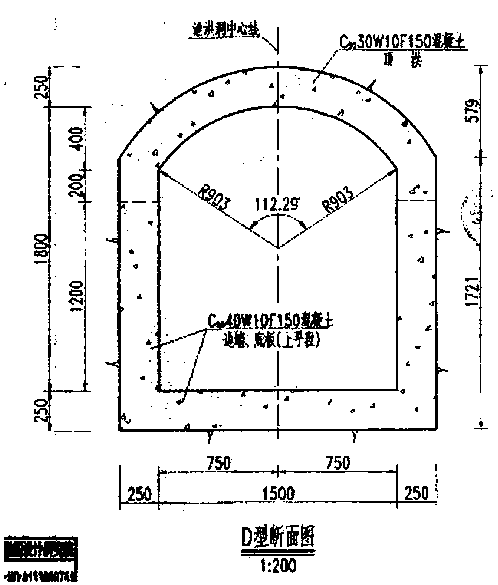

[0079] Intelligent moisturizing and spraying maintenance of lining concrete in the non-pressure section of the flood discharge tunnel of Baihetan Hydropower Station

[0080] (1) Basic information

[0081] The Baihetan Hydropower Station is located in Ningnan County, Sichuan Province, and Qiaojia County, Yunnan Province, on the lower reaches of the Jinsha River. It is a control project for the development and management of the Yangtze River. The installed capacity of the power station is 14,004MW, and the annual average power generation is 60.241 billion kW·h. It is the second largest hydropower station in the world (after the Three Gorges). The hub project is composed of main buildings such as barrage, flood discharge and energy dissipation buildings and water diversion power generation system. The barrage is a concrete hyperbolic arch dam with a maximum height of 289.0m. The flood discharge facilities include 6 surface holes of the dam, 7 deep holes and 3 flood discharge t...

Embodiment 3

[0105] Baihetan Hydropower Station Dam Concrete Moisturizing and Sprinkling Maintenance Intelligentization

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com