Resin complex-containing rubber composition and application

A technology of rubber composition and resin compound, applied in the field of rubber industry, can solve the problems of reducing the protection of the adhesive layer, the degradation of damp heat aging performance, and the damage of the adhesive layer, and achieves the improvement of dynamic adhesive force, high modulus, resistance to Good aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

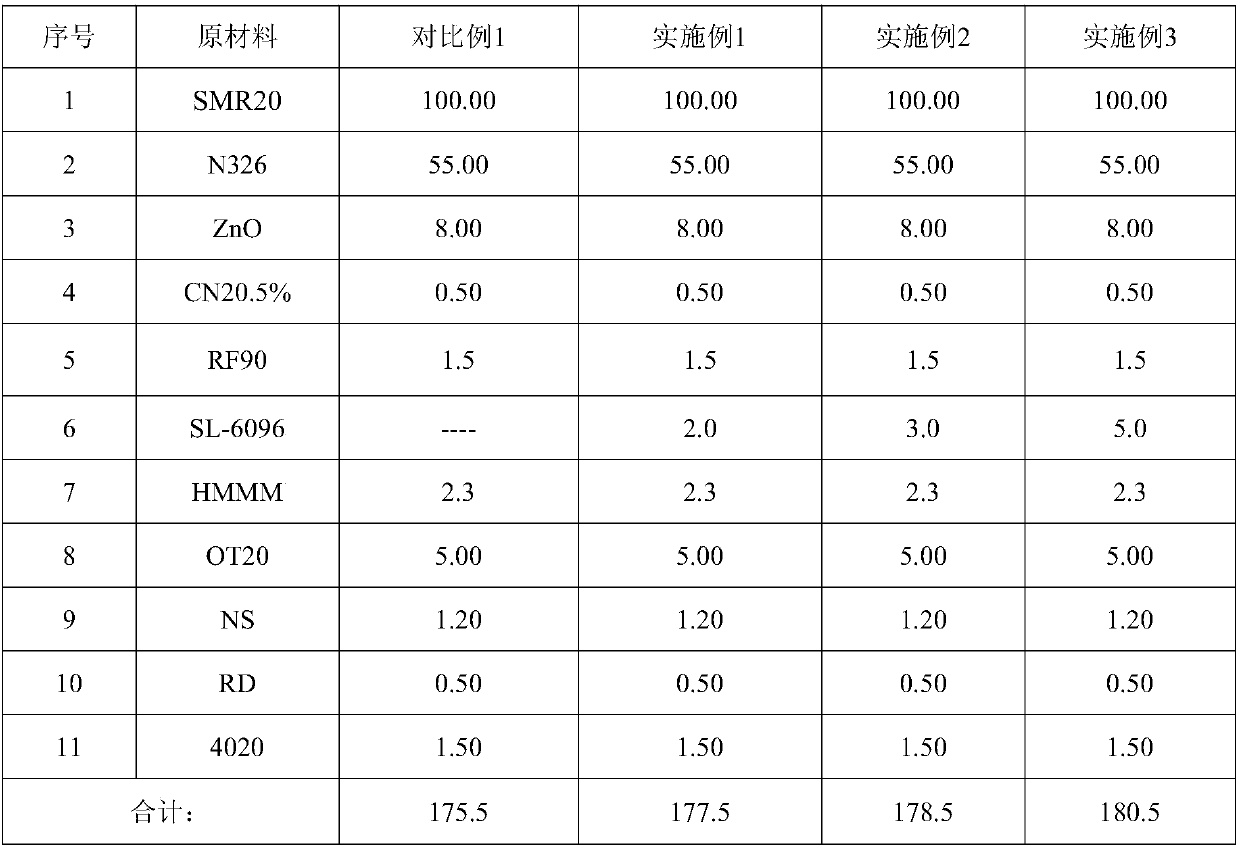

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. It should be pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they are all deemed to be included in the present invention.

[0025] Other components and source in embodiment and comparative example rubber composition are as follows:

[0026] Natural rubber, SMR20, product from Malaysia;

[0027] Carbon black N326, Cabot (China) Investment Co., Ltd.;

[0028] Zinc Oxide, Dalian Zinc Oxide Factory;

[0029] Cobalt salt, CN20.5%, American Shepherd product;

[0030] HMMM, Jinan Baiyi Chemical Co., Ltd.;

[0031] Metaformic resin, RF90, product of Changzhou Changjing Chemical Co., Ltd.

[0032] Antiaging agent 4020, Jiangsu Sunon Chemical Co., Ltd.;

[0033] Antiaging agent RD, Jiangsu Sunon Chemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com