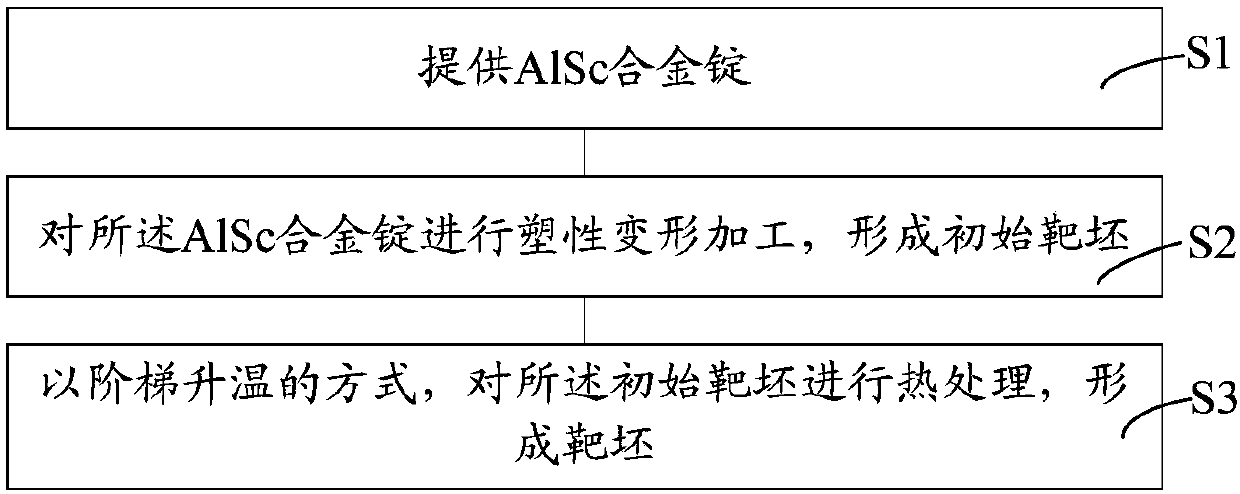

Manufacturing method of target blank and target assembly

A manufacturing method and technology of target blanks, which are applied in the field of sputtering targets, can solve the problems that the sputtering performance of target components needs to be improved, and achieve the effects of improving heating uniformity, uniform crystal orientation, and improving sputtering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] AlSc alloys are gradually used in the manufacture of target blanks because of their superior properties such as corrosion resistance, mechanical strength, toughness, heat resistance, plasticity and weldability. In the manufacturing process of the target blank, the current heat treatment method for the AlSc alloy ingot is mainly: placing the AlSc alloy ingot in a heating furnace, and performing heat treatment on the AlSc alloy ingot.

[0027] However, in the heat treatment process, it is difficult to ensure that the temperature in the heating furnace is stable, and it is difficult to ensure that the AlSc alloy ingot is heated evenly, thus causing the microstructure of the AlSc alloy ingot to be inconsistent in the transverse and longitudinal directions due to uneven heating, The crystal orientation uniformity and grain size uniformity of the formed target blank are poor, which makes it difficult for the formed target blank to meet the requirements of target sputtering.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com