Cholera-diagnosing apparatus with recyclable and easily-dismantlable driving members

A recycling and cholera technology, applied in the field of analysis and testing, can solve the problems of large flow resistance, large flow resistance, and troublesome operation of inner surface modification of PDMS channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

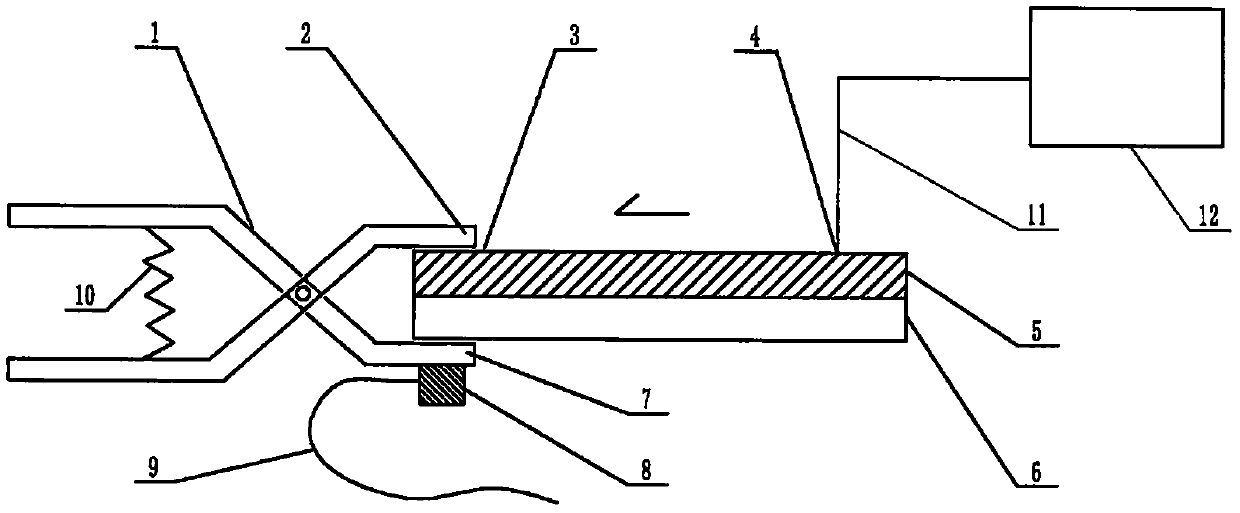

[0073] in figure 1 In the embodiment shown in the present case, the structure of the device includes a multi-channel microfluidic chip. The structure of the microfluidic chip includes a substrate 5 and a cover sheet 6 that are attached to each other and mounted together. The substrate 5 The cover sheet 6 and the cover sheet 6 are both plate-like or sheet-like objects, and the surface of the substrate 5 facing the cover sheet 6 contains a channel structure formed by a molding process or an etching process, and the base sheet is attached to each other and mounted together. The sheet 5 and the cover sheet 6 are jointly constructed to form a microfluidic chip containing a pipe structure. The structure of the pipe is located at the junction area where the substrate 5 and the cover sheet 6 are attached to each other. The sampling end 4 of the microfluidic chip is connected with the terminal 3, the sampling end 4 is the injection end of the sample solution of the microfluidic chip, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com