Preparation and application of amorphous TiO2 thin-layer coated three-dimensional carbon network loaded SnO2 nano-particle composite material

A nanoparticle and network-loaded technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of large volume change, slow ion transmission rate, poor conductivity, etc., and achieve material The effect of uniform structure, excellent shape and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

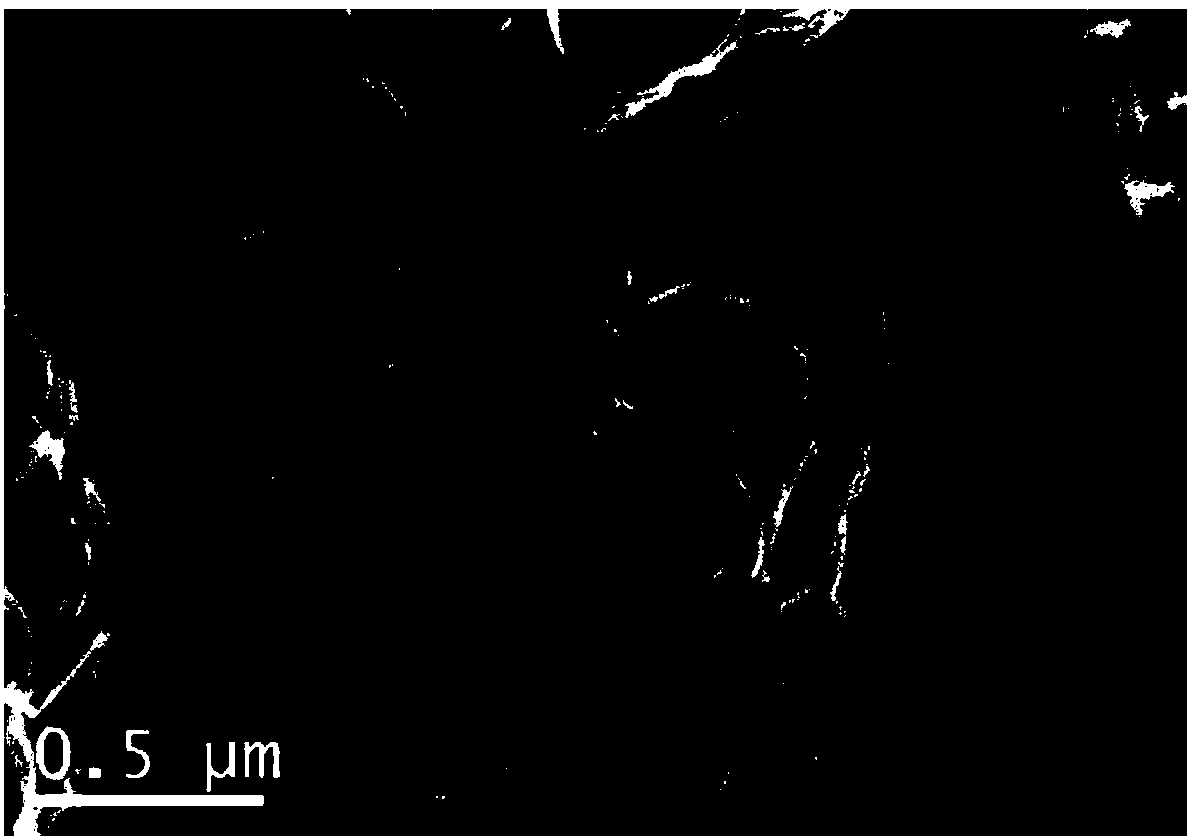

[0025] Weigh 30g of sodium chloride, 1.80g of tin tetrachloride pentahydrate and 3.60g of citric acid, add 200mL of deionized water to prepare a mixed solution; use the spray drying method to obtain the precursor powder. Take 10g of precursor powder and spread it in the ark, and place the ark stably in the constant temperature zone of the high-temperature tube furnace. Ar is used as a protective atmosphere, and the temperature in the furnace is raised to 600° C. at a heating rate of 10° C. / min, and kept for 2 hours to complete the calcination of the material. Take out the powder and remove the NaCl template with deionized water to obtain a three-dimensional carbon network loaded SnO 2 Nanoparticle composites. Take 0.1g three-dimensional carbon network loaded SnO 2 The nanoparticle composite material powder was dispersed in 100 mL of absolute ethanol to obtain a dispersion liquid, and then 0.4 mL of concentrated ammonia water was added dropwise to the dispersion liquid, and s...

Embodiment 2

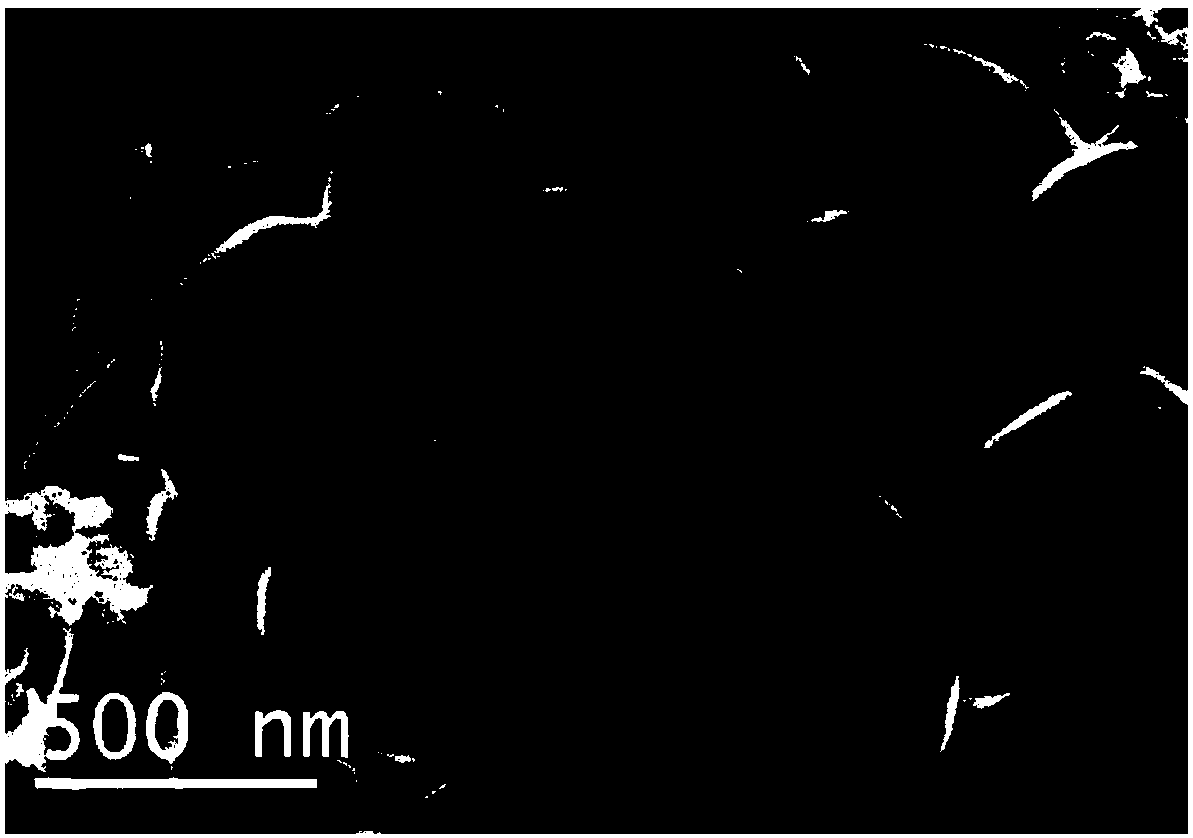

[0027] Weigh 30g of sodium chloride, 1.80g of tin tetrachloride pentahydrate and 3.60g of citric acid, add 200mL of deionized water to prepare a mixed solution; use the spray drying method to obtain the precursor powder. Take 10g of precursor powder and spread it in the ark, and place the ark stably in the constant temperature zone of the high-temperature tube furnace. Ar is used as a protective atmosphere, and the temperature in the furnace is raised to 600° C. at a heating rate of 10° C. / min, and kept for 2 hours to complete the calcination of the material. Take out the powder and remove the NaCl template with deionized water to obtain a three-dimensional carbon network loaded SnO 2 Nanoparticle composites. Take 0.1g three-dimensional carbon network loaded SnO 2 The nanoparticle composite material powder was dispersed in 100 mL of absolute ethanol to obtain a dispersion liquid, and then 0.4 mL of concentrated ammonia water was added dropwise to the dispersion liquid, and sti...

Embodiment 3

[0030] Weigh 30g of sodium chloride, 1.80g of tin tetrachloride pentahydrate and 3.60g of citric acid, add 200mL of deionized water to prepare a mixed solution; use the spray drying method to obtain the precursor powder. Take 10g of precursor powder and spread it in the ark, and place the ark stably in the constant temperature zone of the high-temperature tube furnace. Ar is used as a protective atmosphere, and the temperature in the furnace is raised to 600° C. at a heating rate of 10° C. / min, and kept for 2 hours to complete the calcination of the material. Take out the powder and remove the NaCl template with deionized water to obtain a three-dimensional carbon network loaded SnO 2 Nanoparticle composites. Take 0.1g three-dimensional carbon network loaded SnO 2 The nanoparticle composite material powder was dispersed in 100 mL of absolute ethanol to obtain a dispersion liquid, and then 0.4 mL of concentrated ammonia water was added dropwise to the dispersion liquid, and s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap