Method for treating solvent in lithium hexafluorophosphate electrolyte

A technology of lithium hexafluorophosphate and processing method, which is applied to circuits, electrical components, secondary batteries, etc., can solve the problems of difficult production dehydration and high viscosity, achieve good operability and practicability, quality control and cost reduction, and speed up production progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The solvent of the lithium ion electrolyte is a mixed solvent, which includes ethylene carbonate solvent and other carbonate organic solvents, and the weight percentage of ethylene carbonate solvent in the mixed solvent is: 10% to 50%; The weight percent of the ester organic solvent is: 50% to 90%;

[0026] The processing method includes the following steps:

[0027] 1) Liquefaction treatment:

[0028] After sealing the ethylene carbonate solvent, place it in an oven, adjust the temperature of the oven to 70-90°C, and place it for 10-14 hours, so that the ethylene carbonate solvent is evenly heated and liquefied;

[0029] 2) Dehydration treatment:

[0030] Sampling and analyzing the water content of the liquefied ethylene carbonate solvent and other carbonate solvents, then inject other carbonate solvents into the dehydration treatment equipment first, and then inject the ethylene carbonate solvent into the dehydration equipment for dehydration treatment , until the ...

Embodiment 2

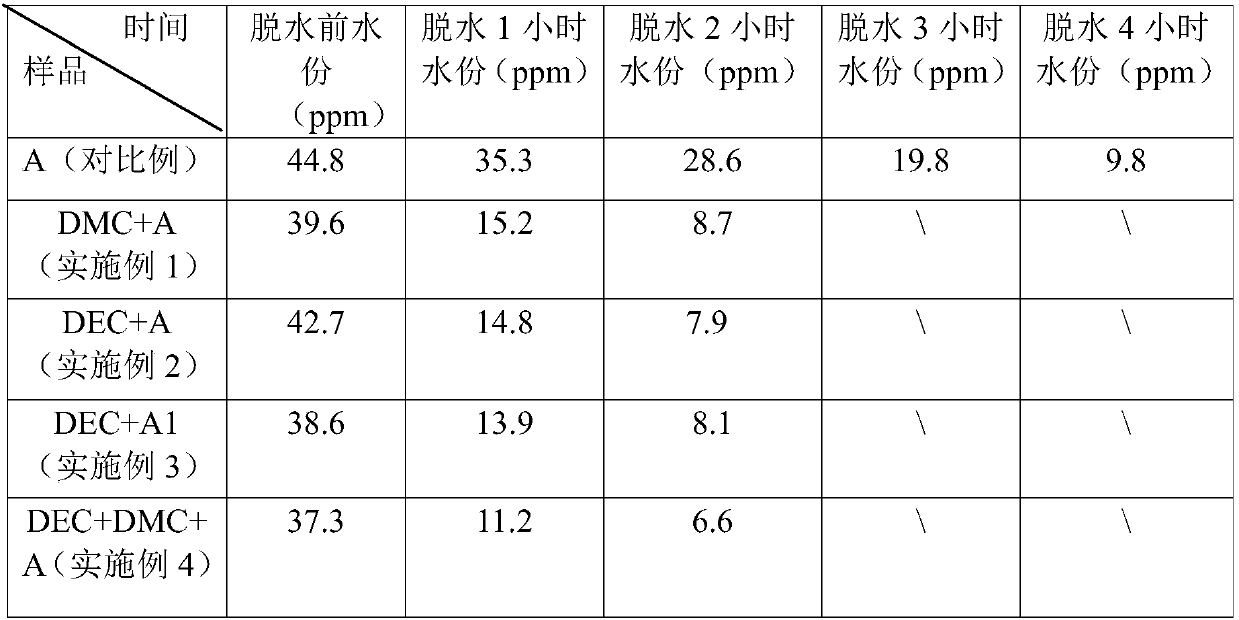

[0033] The difference between this embodiment 2 and the above-mentioned embodiment 1 is that: in the ethylene carbonate production system with heat preservation at 30 degrees and no heat tracing, 400 kilograms of diethyl carbonate raw materials are injected first, and then 400 kilograms of liquefied ethylene carbonate are injected . Then turn on the circulating pump for 15 minutes, take a sample and analyze the moisture before dehydration. Then open the relevant valves of the production system to start dehydration. Samples were then taken every hour for moisture analysis. Labeled as sample DEC+A.

Embodiment 3

[0035] The difference between this embodiment 2 and the above-mentioned embodiment 1 is that: in the ethylene carbonate production system with heat preservation at 20 degrees and no heat tracing, 800 kilograms of diethyl carbonate raw materials are injected first, and then 400 kilograms of liquefied ethylene carbonate are injected . Then turn on the circulating pump for 15 minutes, take a sample and analyze the moisture before dehydration. Then open the relevant valves of the production system to start dehydration. Samples were then taken every hour for moisture analysis. Labeled as sample DEC+A1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com