Novel photocatalyst K-g-C3N4 as well as preparation and application thereof

A photocatalyst, k-g-c3n4 technology, applied in the field of photocatalysis, can solve the problem that the catalytic performance of photocatalyst has not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

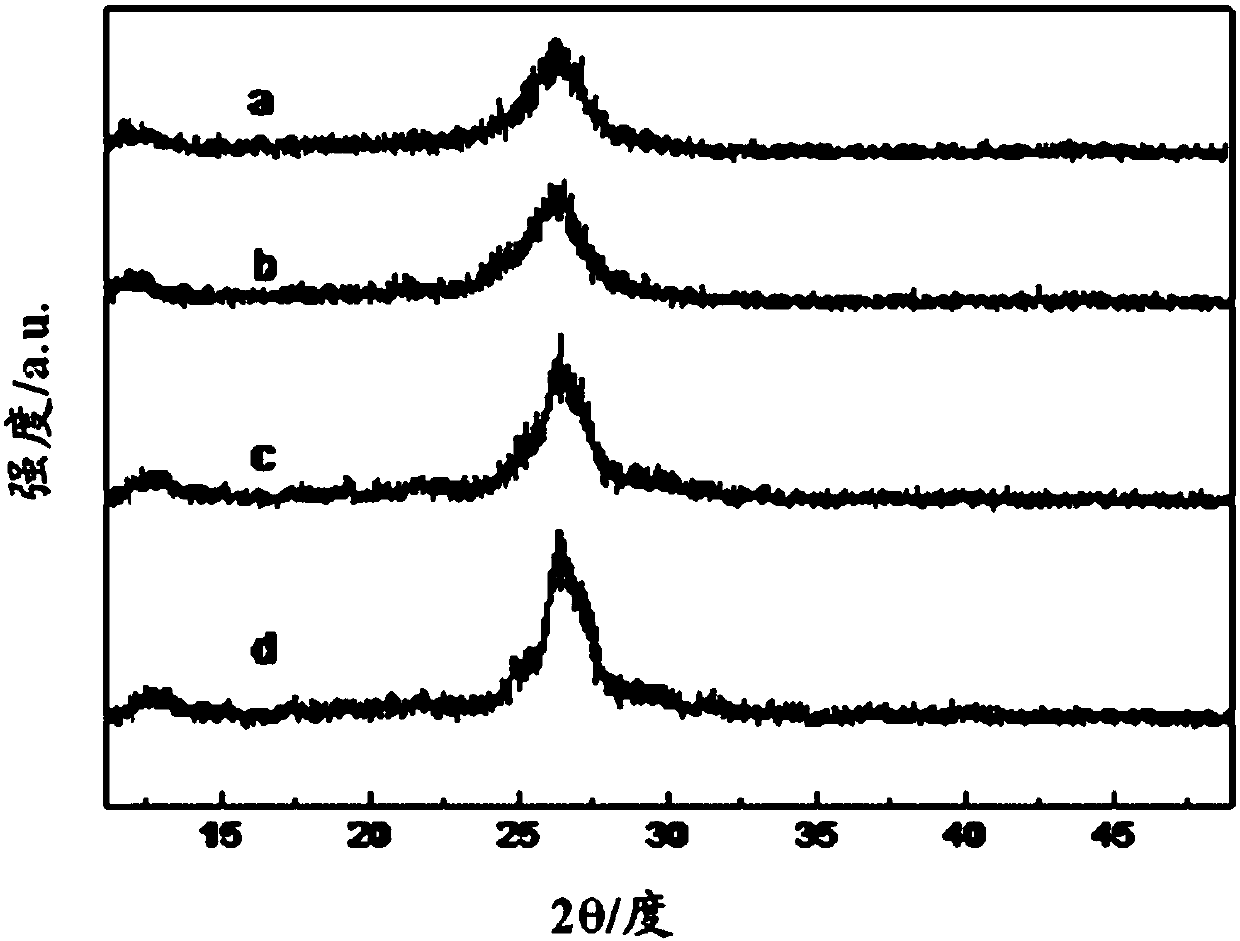

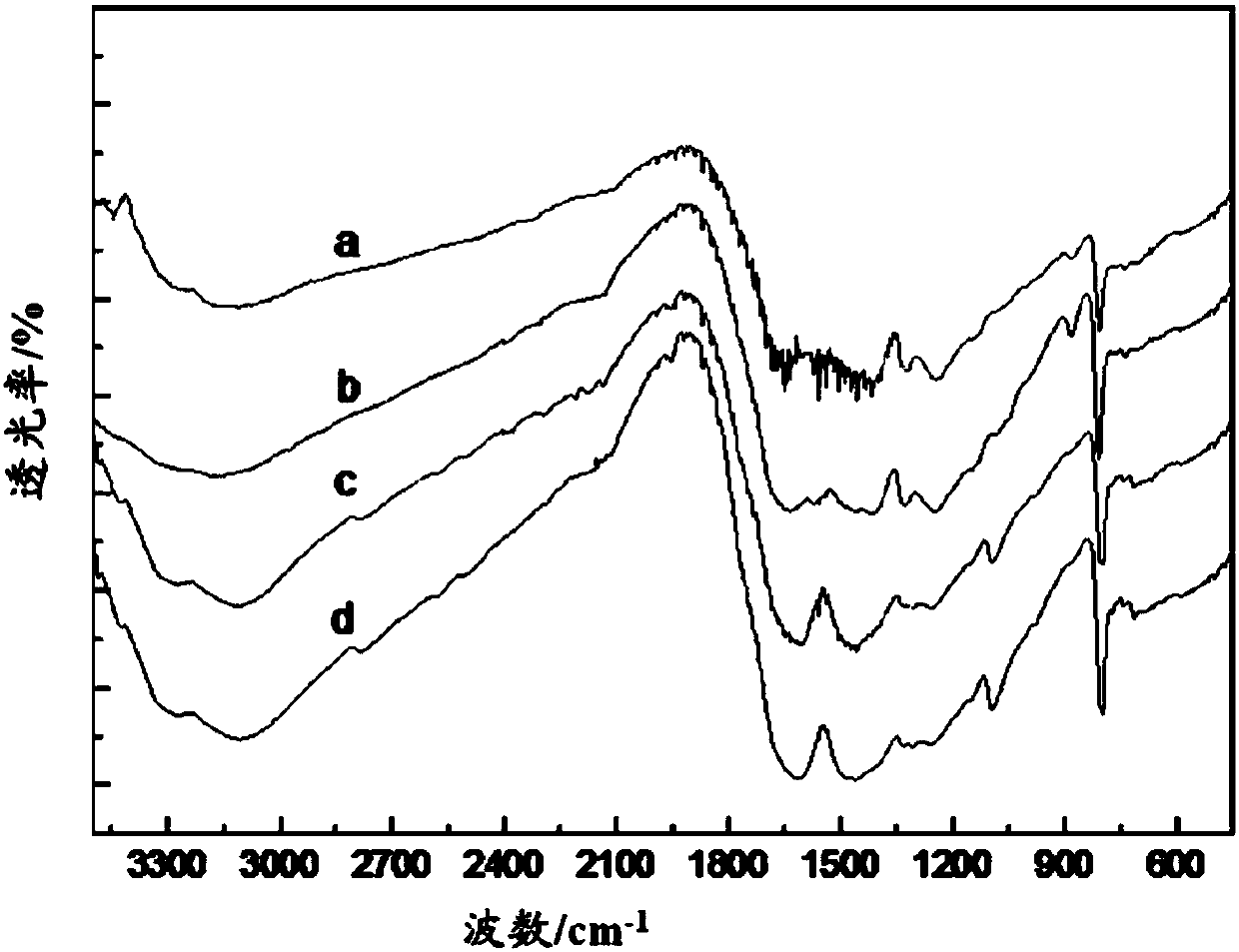

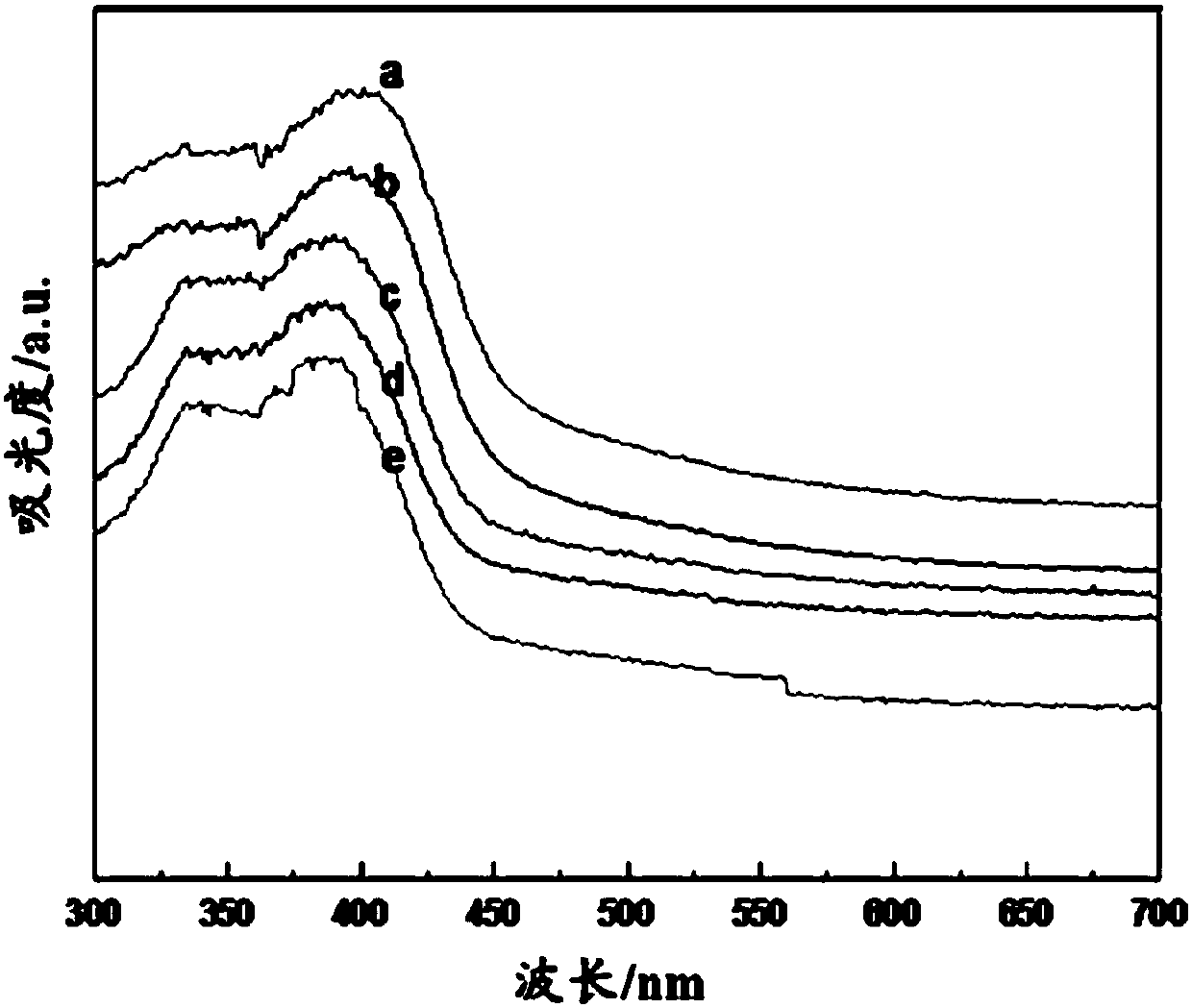

Embodiment 1

[0047] Accurately weigh 2.0000g of dicyandiamide into a 50mL beaker, add about 10mL of deionized water to dissolve. Under vigorous stirring, after dicyandiamine is completely dissolved, accurately measure 10 mL of potassium hydroxide solution (concentration is 0.02 mol / L) with a graduated cylinder and add it to the reaction system to obtain a suspension;

[0048] Heat the obtained suspension to 100°C, remove a large amount of water in the reaction system, and dry the solid in an oven at 80°C;

[0049] Put the evaporated solids in a crucible and place them together in a muffle furnace for calcination at 550°C for 2 hours, with a heating rate of 5°C min -1 After the calcination is completed, the product is cooled to room temperature, ground into powder with an agate mortar, placed in a sample bag, sealed and protected from light, stored in a dry place, and labeled. The obtained product was named K(0.02)-CN.

Embodiment 2

[0051] Use an electronic balance to accurately weigh 2.0000g of dicyandiamide and place it in a 50mL beaker, add about 10mL of deionized water to dissolve, stir vigorously, and after the dicyandiamine is completely dissolved, use a graduated cylinder to accurately measure 10mL of hydrogen Potassium oxide solution (concentration is 0.05mol / L) is added in the reaction system, obtains suspension;

[0052] Heat the obtained suspension to 100°C, remove a large amount of water in the reaction system, and dry the solid in an oven at 80°C;

[0053] Then calcined in a muffle furnace at 550°C for 2h, the heating rate is 5°Cmin -1 , when the product is cooled to room temperature, grind it into powder with an agate mortar, put it in a sample bag, seal it away from light, store it in a dry place, and stick a label. The obtained product was named K(0.05)-CN.

Embodiment 3

[0055] Accurately weigh 2.0000g of dicyandiamide and place it in a 50mL beaker, add about 10mL of deionized water to dissolve, stir vigorously, after the dicyandiamide is completely dissolved, accurately measure 10mL of potassium hydroxide solution with a graduated cylinder (Concentration is 0.07mol / L) is added in the reaction system, obtains suspension;

[0056] Heat the obtained suspension to 100°C, remove a large amount of water in the reaction system, and dry the solid in an oven at 80°C;

[0057] Put the evaporated solid in a crucible, and then calcinate it in a muffle furnace at 550°C for 2h, and the heating rate is 5°Cmin -1 After calcination, the product is cooled to room temperature, ground into powder with an agate mortar, placed in a sample bag, sealed and protected from light, stored in a dry place, and labeled. The obtained product was named K(0.07)-CN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com