Synthesis method of graphite phase carbonitride homotype heterojunction photocatalysis material with multilayer structure and application

A technology of graphitic carbon nitride and photocatalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of less research, small specific surface area, and serious photogenerated electron-hole recombination and other problems, to achieve the effects of mild conditions, enhanced absorption, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Synthesis of graphite phase carbon nitride homogeneous heterojunction photocatalytic material with multi-level structure, the method is as follows:

[0024] Step 1. At room temperature, weigh 0.126g of melamine powder and 0.129g of cyanuric acid powder, disperse them in 150ml of deionized water, and stir for 4h at a speed of 8000r / min to obtain a melamine / cyanuric acid suspension; weigh 0.5 g urea, dissolved in 5mL deionized water to obtain 0.1g / ml urea aqueous solution;

[0025] Step 2, disperse the suspension obtained in step 1 into a hydrothermal kettle, place it in a muffle furnace and heat it at 180°C, react for 6 hours, and cool it down to room temperature naturally; centrifuge to obtain melamine / cyanuric acid that has completed the assembly reaction macromolecular crystals;

[0026] Step 3: Add 0.5 g of the melamine / cyanuric acid macromolecular crystal prepared in step 2 to the urea aqueous solution configured in step 1, mix and stir for 4 hours, a...

Embodiment 2

[0033] Embodiment 2: Synthesis of graphite phase carbon nitride homogeneous heterojunction photocatalytic material with multi-level structure, the method is as follows:

[0034] Step 1, with embodiment 1 step 1, make melamine / cyanuric acid suspension and 0.2g / ml urea aqueous solution;

[0035] Step 2, make melamine / cyanuric acid macromolecular crystal with embodiment 1 step 2;

[0036] Step 3, adding 1 g of the melamine / cyanuric acid macromolecular crystal prepared in step 2 to the urea aqueous solution configured in step 1, mixing and stirring for 6 hours, and centrifuging to obtain a urea-(melamine / cyanuric acid) composite precursor;

[0037] Step 4. The urea-(melamine / cyanuric acid) composite precursor prepared in step 3 was dried overnight at 60°C, and then calcined at 520°C for 2 hours in a nitrogen atmosphere in a tube furnace to obtain g-C 3 N 4 Nanoparticles deposited on g-C 3 N 4 Multi-hierarchical g-C on microtubes 3 N 4 The homogeneous heterojunction photocat...

Embodiment 3

[0041] Example 3 Synthesis of a graphitic phase carbon nitride homogeneous heterojunction photocatalytic material with a multi-level structure, the steps are basically the same as in Example 2, the only difference is: in step 4, the calcination temperature is changed from 520 ° C to 500 ° C, and finally with g-C 3 N 4 Nanoparticles deposited on g-C 3 N 4 Multi-hierarchical g-C on microtubes 3 N 4 The homogeneous heterojunction photocatalytic material is denoted as TCNH-3 photocatalyst.

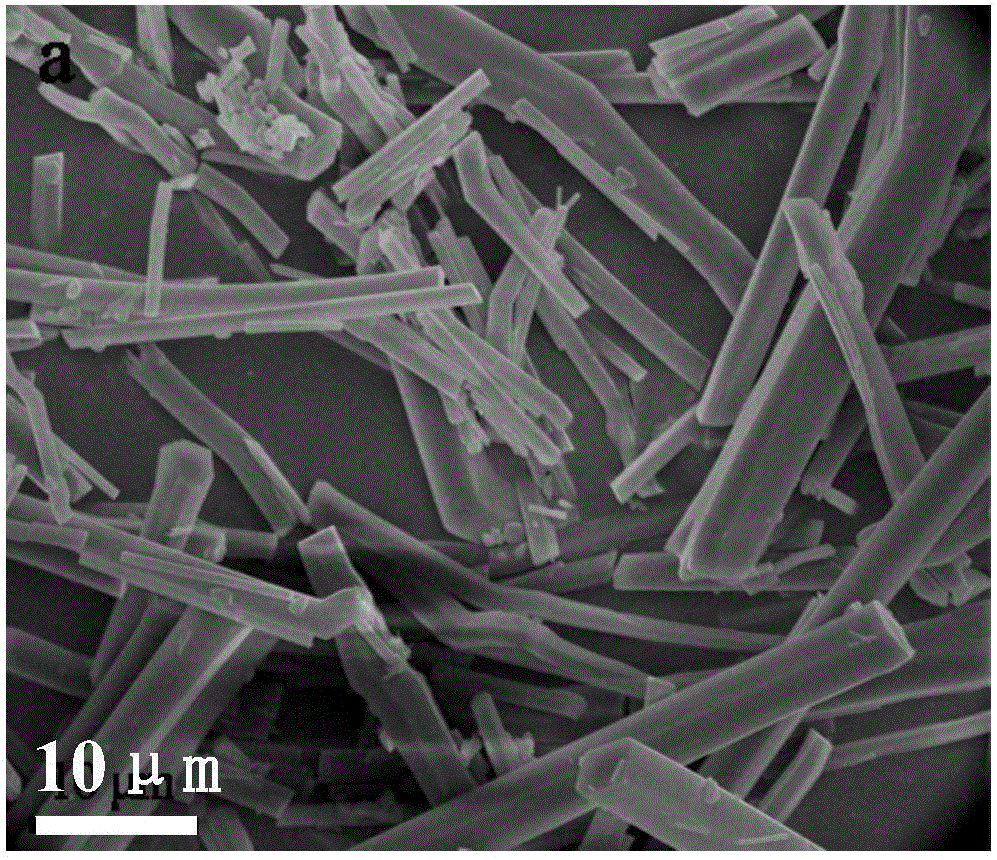

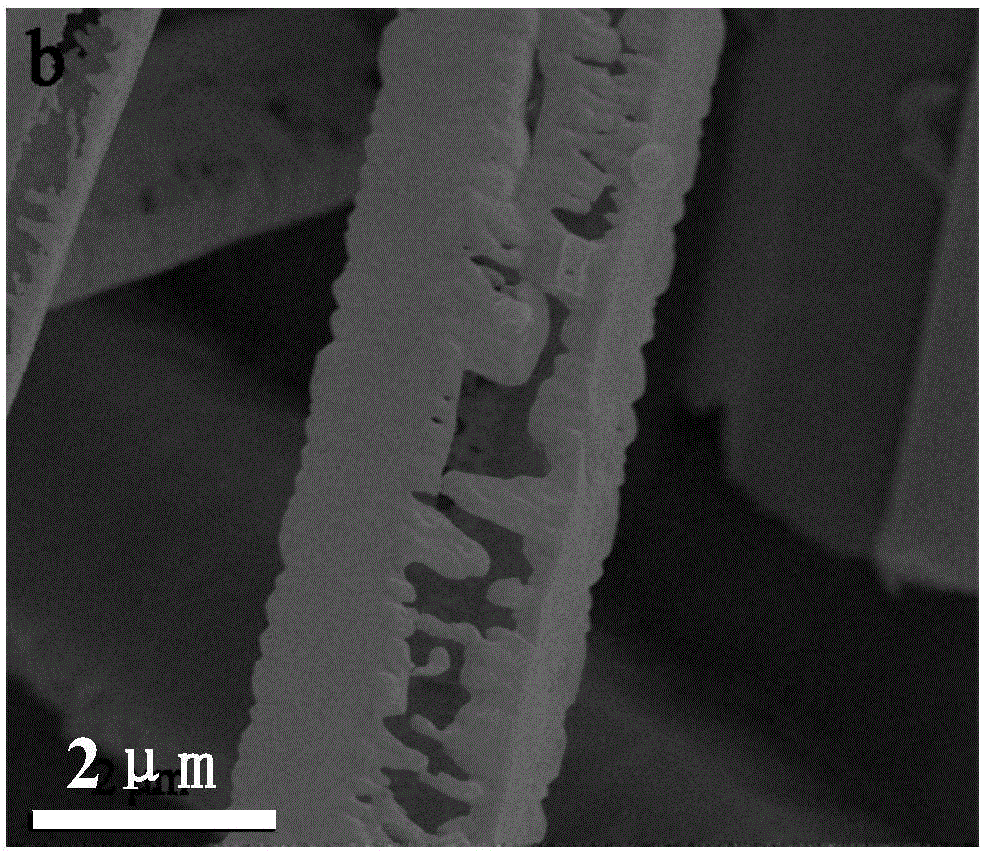

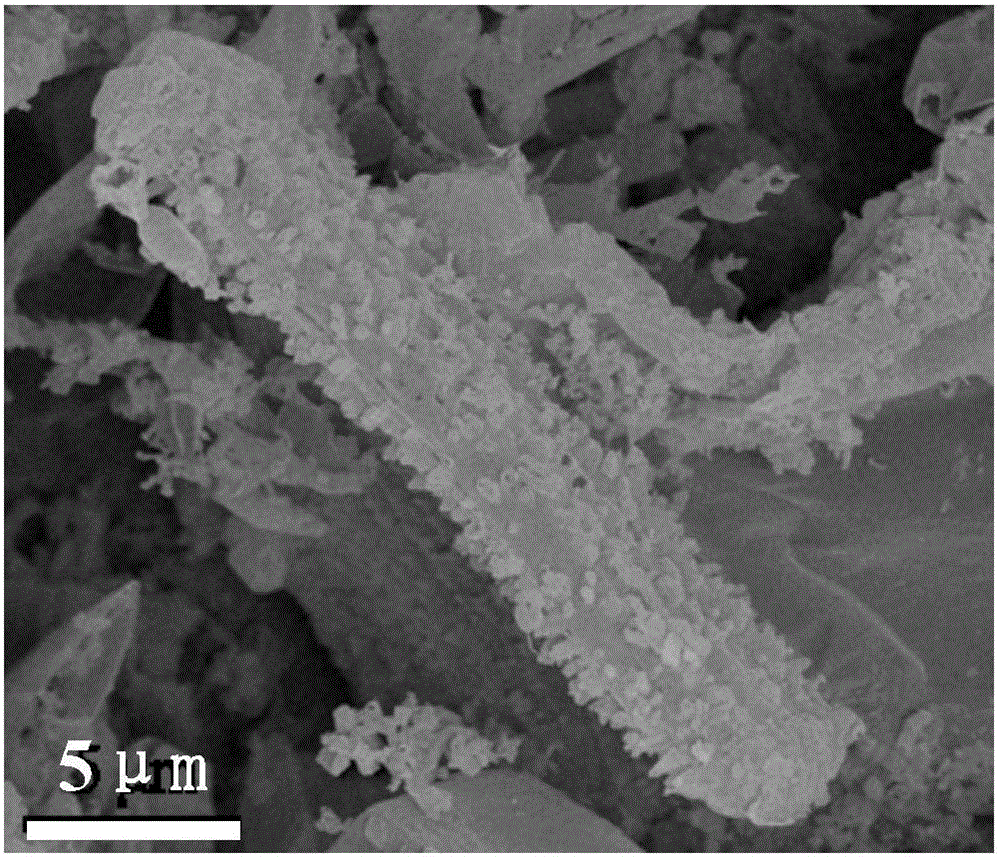

[0042] Observation by scanning electron microscope (SEM), TCNH-1 photocatalyst, TCNH-2 photocatalyst and TCNH-3 photocatalyst obtained in embodiment 1-3 all present the structure of g-C3N4 nanoparticle deposition g-C3N4 microtube, wherein The particle size of g-C3N4 is about 200nm, and they are distributed on the surface of g-C3N4 microtubes with a diameter of about 1.5μm.

[0043] The graphitic phase carbon nitride homogeneous heterojunction photocatalytic material with multi-level stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com