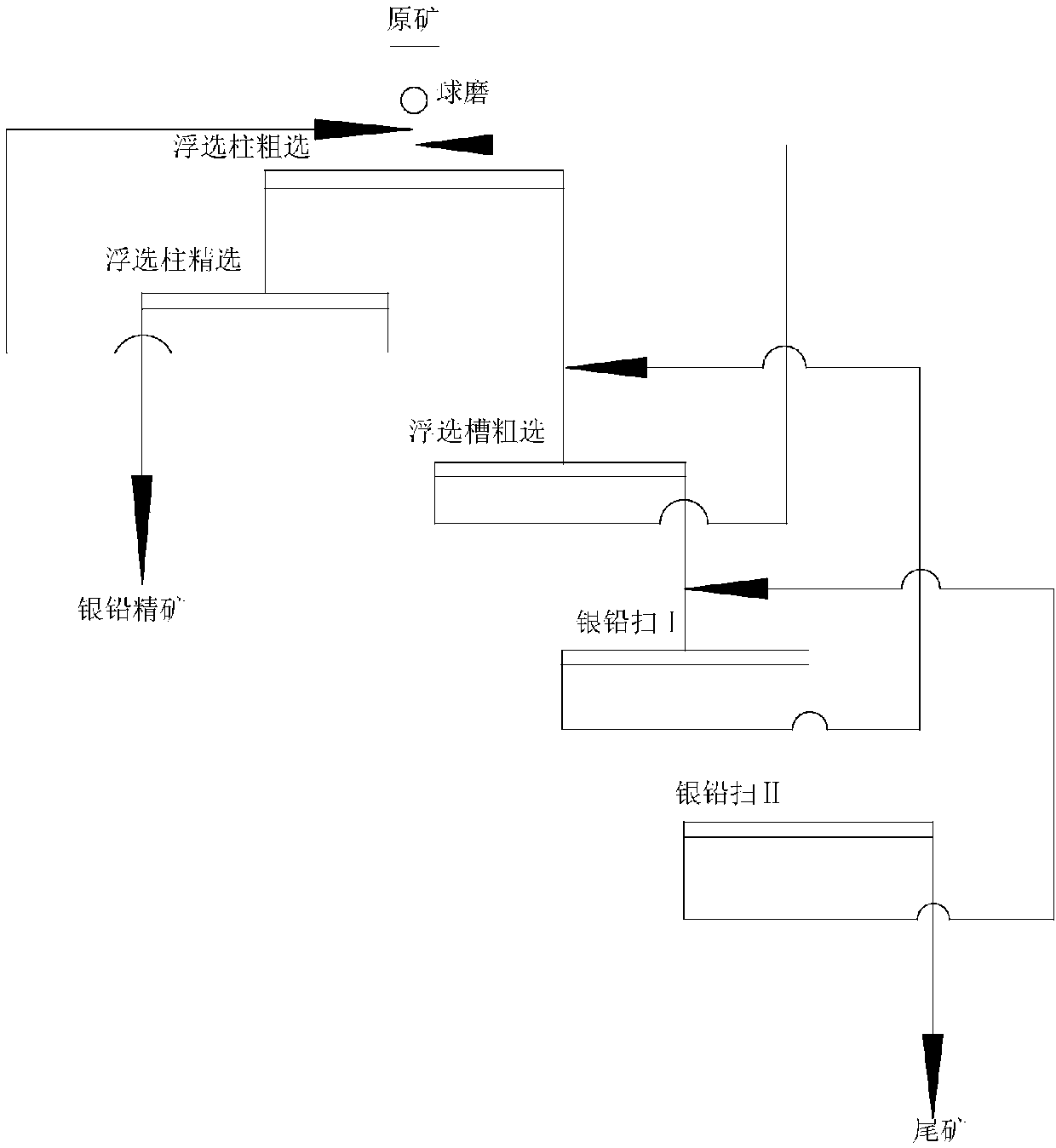

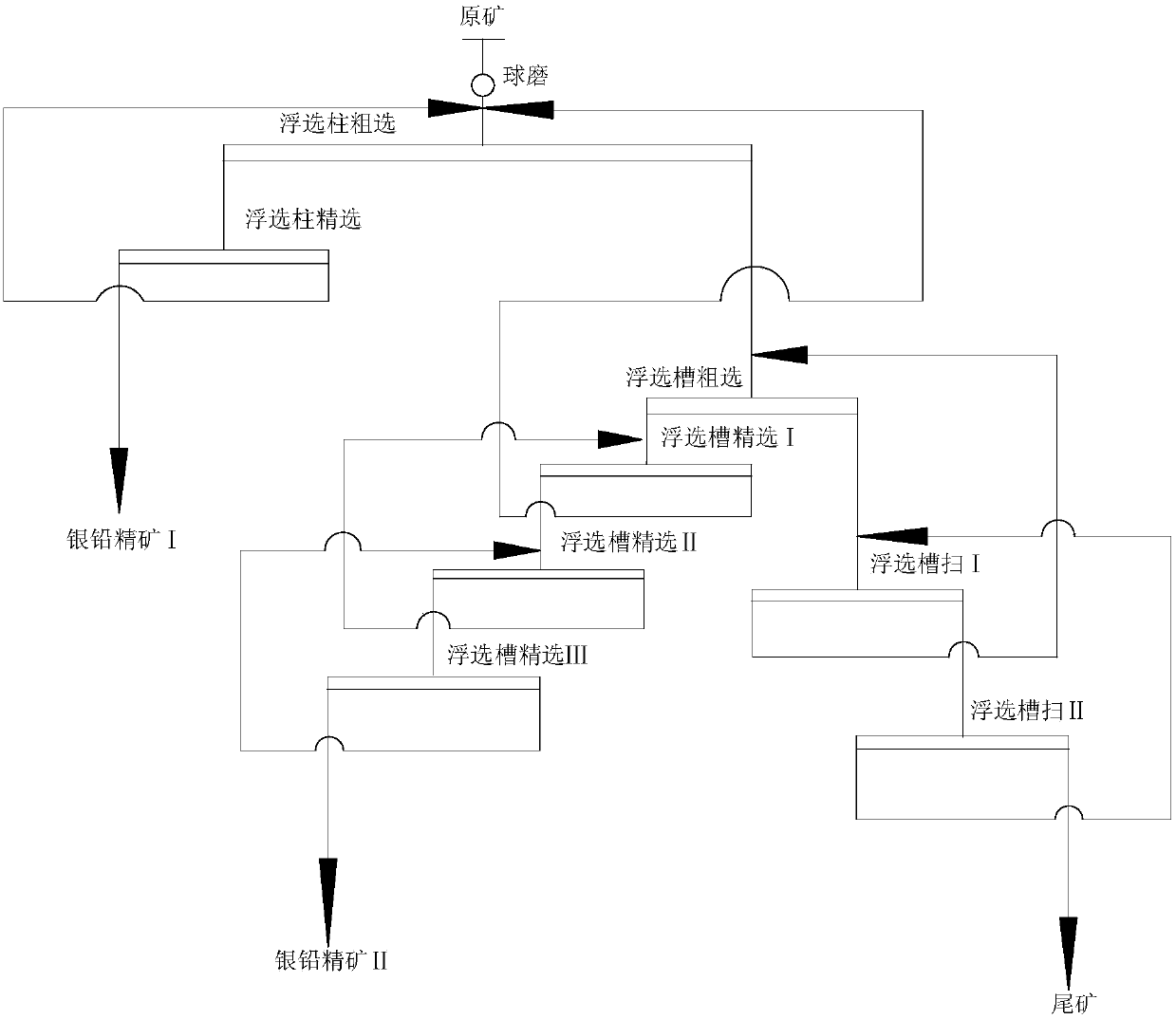

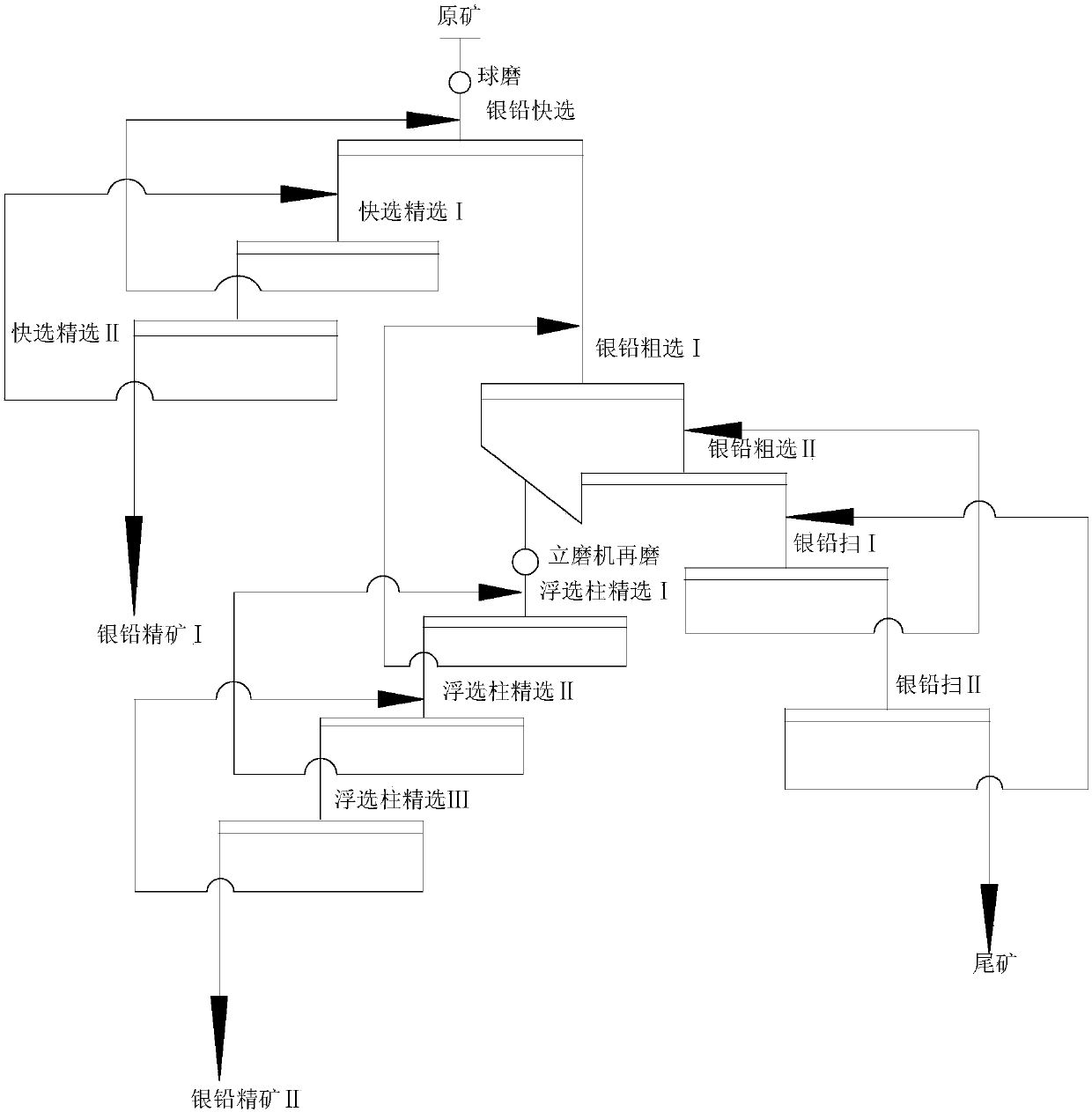

Column-machine jointed segmental asynchronous rough concentrate regrinding and lead selecting method

A coarse concentrate, asynchronous technology, applied in flotation, solid separation and other directions, can solve the problems of complex embedded characteristics, poor beneficiation separation effect, low recovery rate, etc., to improve the recovery rate of silver and lead, and improve the recovery rate of lead , the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The column machine united subsection asynchronous coarse concentrate regrinding method for lead selection includes the following steps:

[0034] A. The raw ore enters the cyclone for grading after being ball milled by the ball mill, and the overflow enters the dense pool to concentrate and then undergoes rapid lead separation by flotation by flotation machine;

[0035] B. After the rapid separation tailings are roughed, the coarse concentrate enters the vertical mill for grinding again, and the cyclone classification overflow is concentrated through the thickening pool and then enters the flotation column for flotation for lead separation.

[0036] The process parameters are as follows: primary grinding pulp PH is 9.20, pulp concentration is 50%, primary grinding fineness -200 mesh is 70%, regrinding fineness -400 mesh is 92.3%, and the chemical system of beneficiation is: BK906 is 85g / t, BK901B is 16g / t, BK204 is 12g / t, zinc sulfate is 1800g / t, and sodium sulfite is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com