A kind of method of synthesizing cetrorelix

A technology of cetrorelix and condensation reagents, which is applied in the field of synthesizing cetrorelix, can solve the problems that the total yield cannot be increased, and achieve the effects of mild conditions, high total yield and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

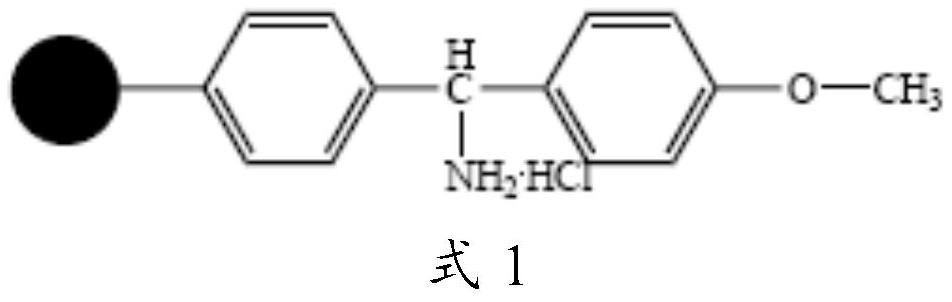

[0049] Embodiment 1: the synthesis of D-Ala-MOBHA resin

[0050] Take 0.15mol Fmoc-D-Ala and 0.15mol HOBt, and dissolve them with an appropriate amount of DMF; take another 0.15mol DIC, and slowly add it to the DMF solution of the protected amino acid under stirring, and stir and react at room temperature for 30 minutes to obtain the activated protected amino acid. Amino acid solution, spare.

[0051] Take 0.05mol of MOBHA resin (substitution value about 0.6mmol / g), swell with DMF for 25 minutes, wash and filter, add activated Fmoc-D-Ala solution, stir at room temperature for 3 hours, remove the reaction solution, and wash with DMF for 3 times Finally, DCM was washed 3 times, and the washing time was 3 minutes each time to obtain Fmoc-D-Ala-MOBHA resin, which was deprotected with 20% PIP / DMF solution for 25 minutes, washed and filtered to obtain D-Ala-MOBHA resin.

Embodiment 2

[0052] Embodiment 2: the synthesis of D-Ala-MOBHA resin

[0053] Take 0.15mol Boc-D-Ala and 0.15mol HOBt, and dissolve them with appropriate amount of DMF; take another 0.15mol DIC, slowly add it into the DMF solution of the protected amino acid under stirring, and stir and react at room temperature for 30 minutes to obtain the activated protected amino acid. Amino acid solution, spare.

[0054] Take 0.05mol of MOBHA resin (substitution value about 0.6mmol / g), swell with DMF for 25 minutes, wash and filter, add activated Fmoc-D-Ala solution, stir at room temperature for 3 hours, remove the reaction solution, and wash with DMF for 3 times Finally, wash with DCM 3 times, each washing time is 3min, to obtain Boc-D-Ala-MOBHA resin, deprotect with 30% TFA / DCM solution for 30 minutes, neutralize with DIEA / DCM solution, wash and filter with DMF and DCM D-Ala-MOBHA resin was obtained.

Embodiment 3

[0055] Embodiment 3: the synthesis of Pro-D-Ala-MOBHA resin

[0056] Take 0.15mol Fmoc-Pro and 0.15mol HOBt, and dissolve them with an appropriate amount of DMF; take another 0.15mol DIC, slowly add it to the protected amino acid DMF solution under stirring, and stir and react at room temperature for 30 minutes to obtain the activated protected amino acid solution .

[0057] Add the above-mentioned activated protected amino acid solution to the D-Ala-MOBHA resin prepared in Example 1, stir and react at room temperature for 3 hours, remove the reaction solution, wash 3 times with DMF, and wash 3 times with DCM, each washing time is After 3 minutes, deprotect with 20% PIP / DMF solution for 25 minutes, wash and filter to obtain Pro-D-Ala-MOBHA resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com