PVC(chlorinated polyvinyl chloride)-C power cable sleeve and production method thereof

A power cable and bushing technology, applied in the field of PVC-C power cable bushing and its production, can solve the problems of inability to meet the requirements of strength and high temperature resistance, inability to meet the requirements of cold resistance, and increased difficulty in installation and transportation, and achieve excellent physical and chemical properties. performance, improved extrusion stability and dimensional stability, resistance to uneven settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

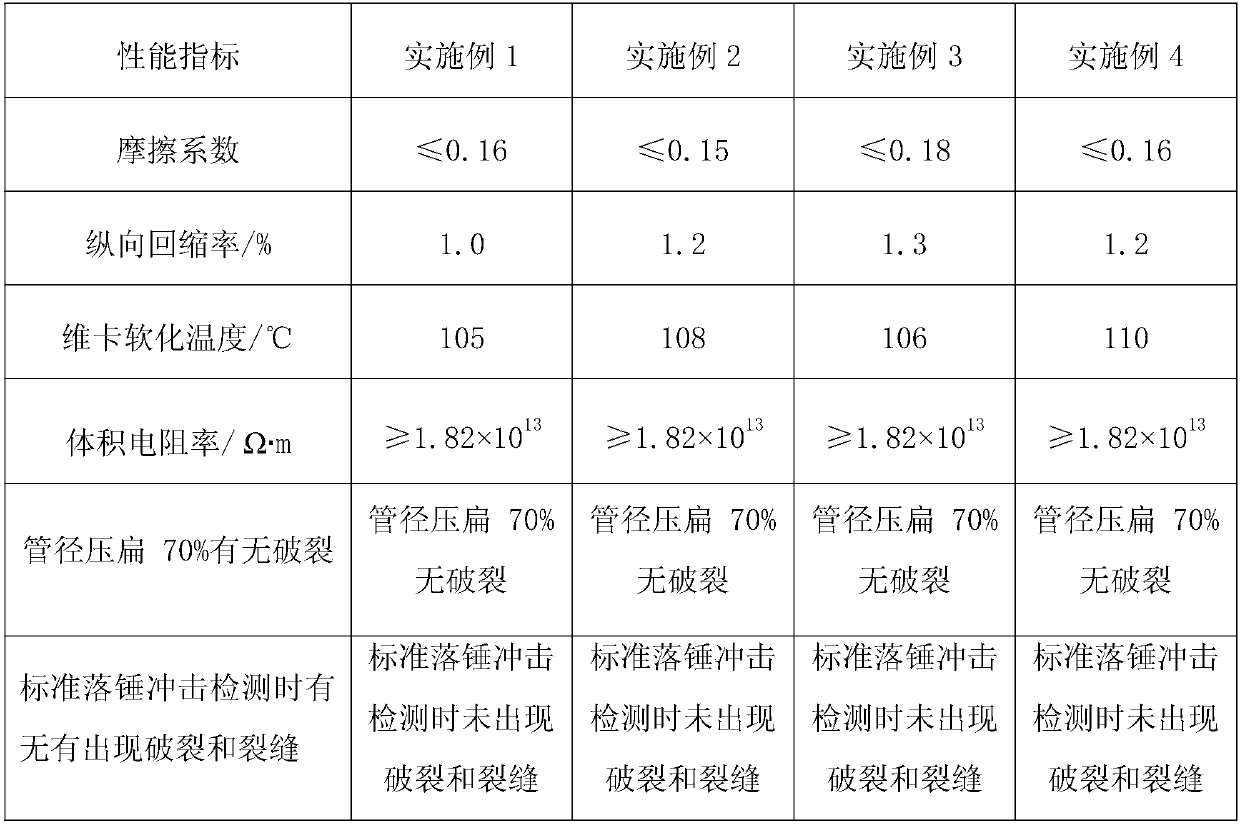

Examples

Embodiment 1

[0033] S1. Mixing of raw materials: 100 parts of chlorinated polyvinyl chloride resin, 20 parts of nanometer anhydrous calcium sulfate, 2 parts of heat conducting agent, 1 part of composite stabilizer, 0.5 part of methyl methacrylate-butadiene-styrene copolymer , 0.2 parts of polypropylene wax and 0.1 parts of coupling agent according to the weight ratio, placed in the material tank of the high-temperature mixer for high-temperature mixing, the mixing temperature is 115-130 ° C, after mixing for 15-30 minutes, the mixed material Cool to 40-55°C and collect for use;

[0034] S2, granulation: send the materials collected in S1 into a granulator for granulation, and control the temperature of the barrel of the granulator at 175-200°C to obtain pellets;

[0035] S3. Pipe making: Cool the pellets obtained in S2 and put them into the barrel, control the temperature of the barrel to 170-220°C, and the extrusion pressure to 35MPa, and then extrude the material through the die of the e...

Embodiment 2

[0037] S1. Mixing of raw materials: 110 parts of chlorinated polyvinyl chloride resin, 25 parts of nanometer anhydrous calcium sulfate, 3 parts of heat conducting agent, 2 parts of composite stabilizer, 1 part of methyl methacrylate-butadiene-styrene copolymer , 0.5 parts of polypropylene wax and 0.2 parts of coupling agent according to the weight ratio, placed in the material tank of the high-temperature mixer for high-temperature mixing, the mixing temperature is 115-130 ° C, after mixing for 15-30 minutes, the mixed material Cool to 40-55°C and collect for use;

[0038] S2, granulation: send the materials collected in S1 into a granulator for granulation, and control the temperature of the barrel of the granulator at 175-200°C to obtain pellets;

[0039] S3. Pipe making: Cool the pellets obtained in S2 and put them into the barrel, control the temperature of the barrel to 170-220°C, and the extrusion pressure to 40MPa, and then extrude the material through the die of the ex...

Embodiment 3

[0041]S1. Mixing of raw materials: 115 parts of chlorinated polyvinyl chloride resin, 28 parts of nano-anhydrous calcium sulfate, 5 parts of heat conducting agent, 2.5 parts of composite stabilizer, and 1.5 parts of methyl methacrylate-butadiene-styrene copolymer , 0.8 parts of polypropylene wax and 0.4 parts of coupling agent according to the weight ratio, placed in the material tank of the high-temperature mixer for high-temperature mixing, the mixing temperature is 115-130 ° C, after mixing for 15-30 minutes, the mixed material Cool to 40-55°C and collect for use;

[0042] S2, granulation: send the materials collected in S1 into a granulator for granulation, and control the temperature of the barrel of the granulator at 175-200°C to obtain pellets;

[0043] S3. Pipe making: Cool the pellets obtained in S2 and put them into the barrel, control the temperature of the barrel to 170-220°C, and the extrusion pressure to 45MPa, and then extrude the material through the die of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com