An in-situ analyzer for nutritive salt and a nutritive salt content analyzing method

An in-situ analyzer and nutrient technology, applied in chemical instruments and methods, analytical materials, chemical method analysis, etc., can solve the problem of poor sample representation, nutrient loss and variation, and no automatic seawater nutrient online analyzer. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

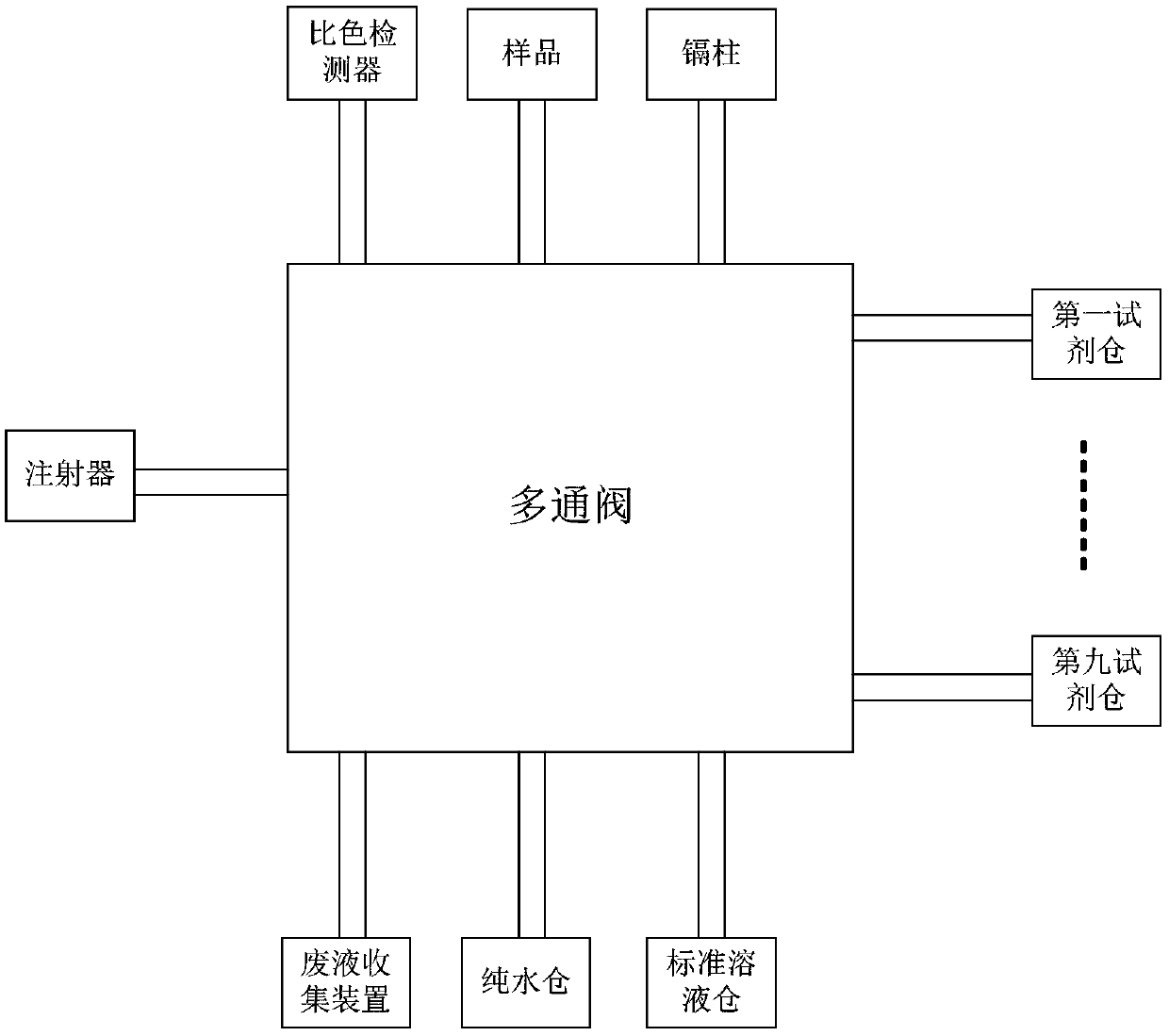

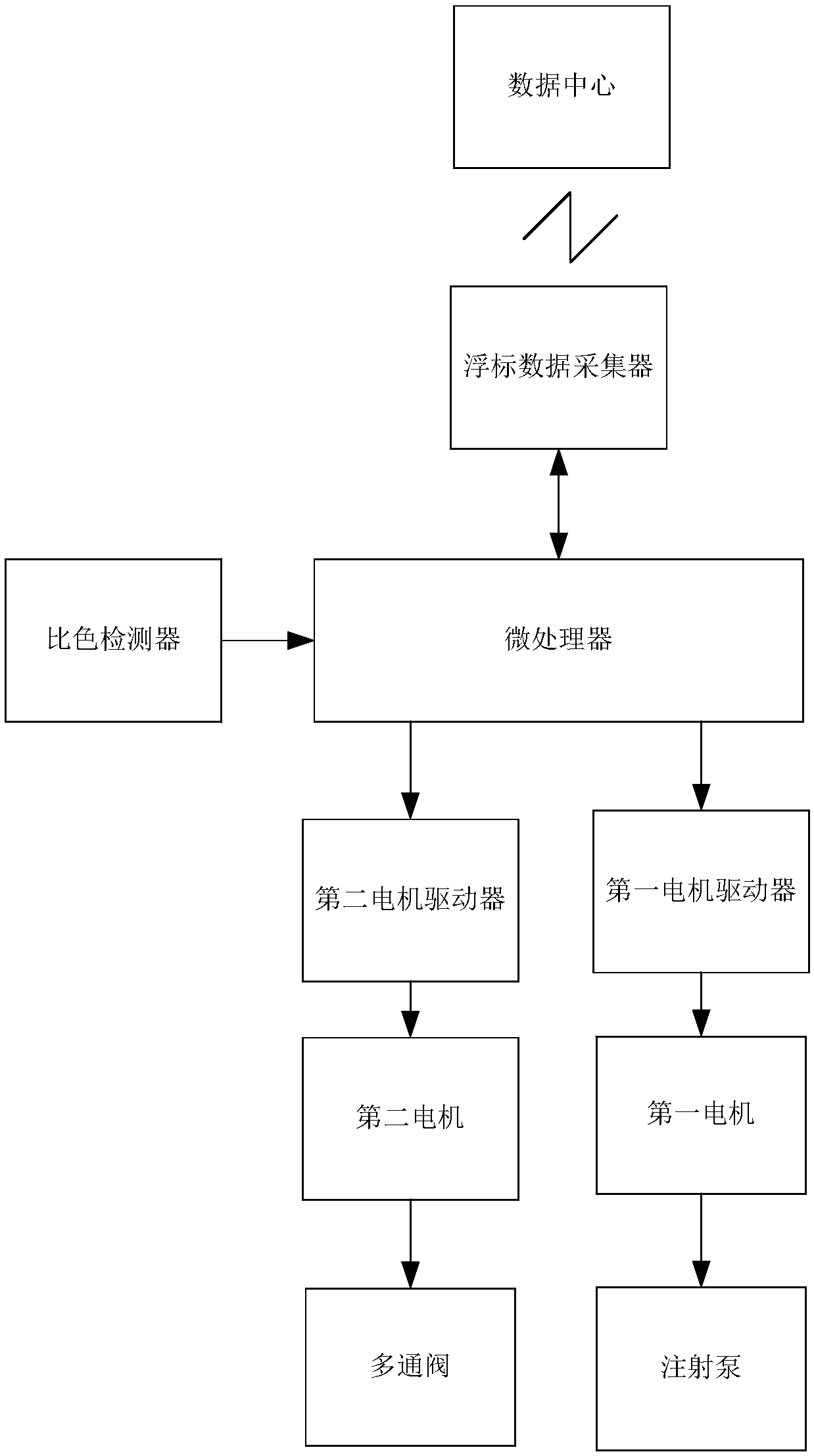

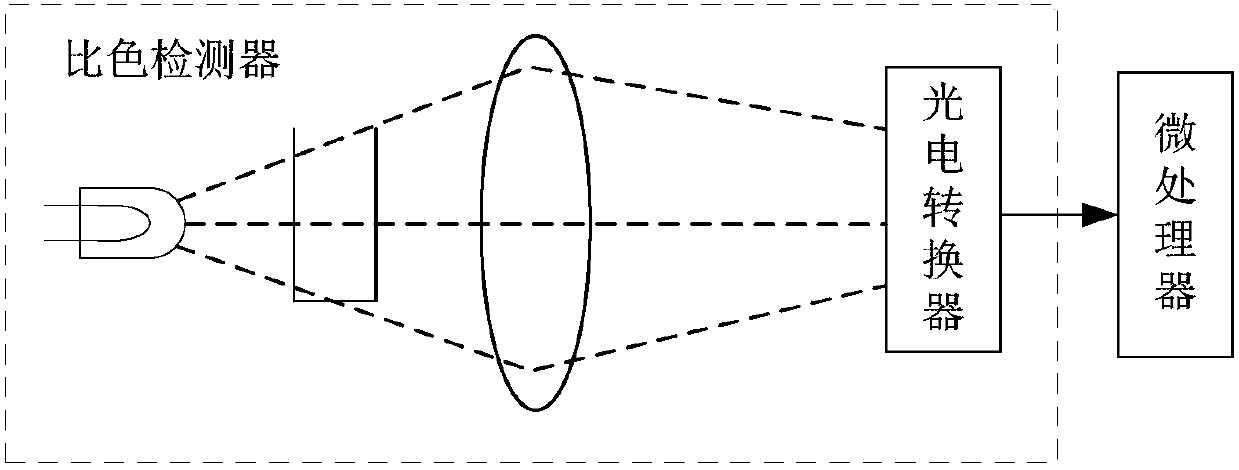

[0106] This embodiment discloses an in-situ analyzer for nutrient salts, including a microprocessor, driving components, a multi-way valve, a syringe, a colorimetric detector, a mixing ring, a sample pipeline, a cadmium column, a waste liquid collection device, and a pure water tank , standard solution chambers and various reagent chambers; figure 1 As shown, the syringe, colorimetric detector, mixing ring, sample pipeline, cadmium column, waste liquid collection device, pure water tank, standard solution tank and various reagent tanks are respectively connected to the ports of the multi-port valve. In this example, if figure 2 As shown, the driving part includes a first motor driver, a first motor, a second motor driver and a second motor; the microprocessor is connected to the first motor driver and the first motor in sequence and then connected to the syringe pump of the syringe, for controlling the syringe pump work; the microprocessor is connected to the second motor dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com