PFC inductor

A technology of inductors and winding bobbins, which is applied in the direction of inductors, fixed inductors, transformer/inductor cores, etc., can solve problems such as hindering the development of power supplies, failure of electromagnetic shielding, low power factor, etc., and achieve winding and installation The process is simple, the heat dissipation effect is good, and the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

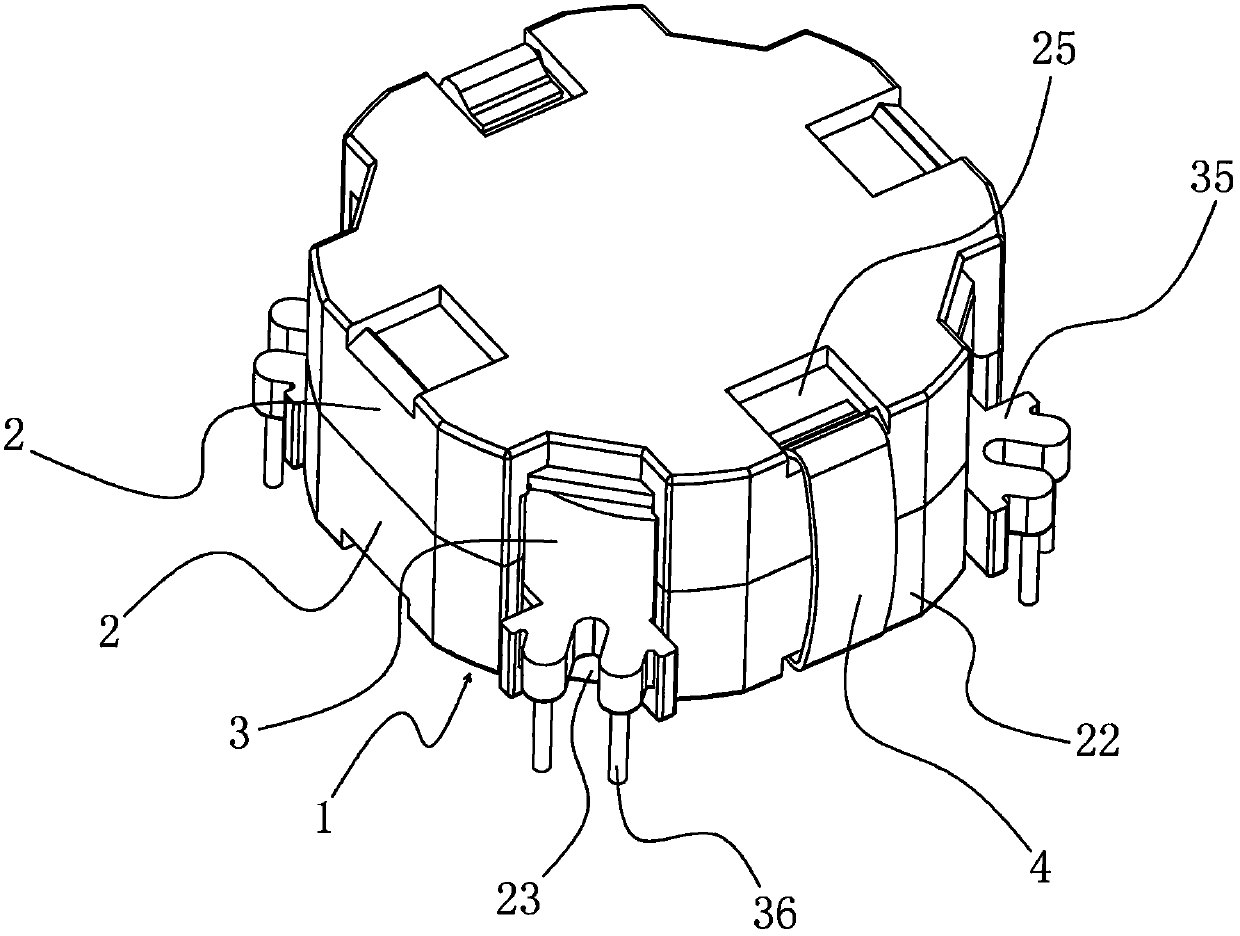

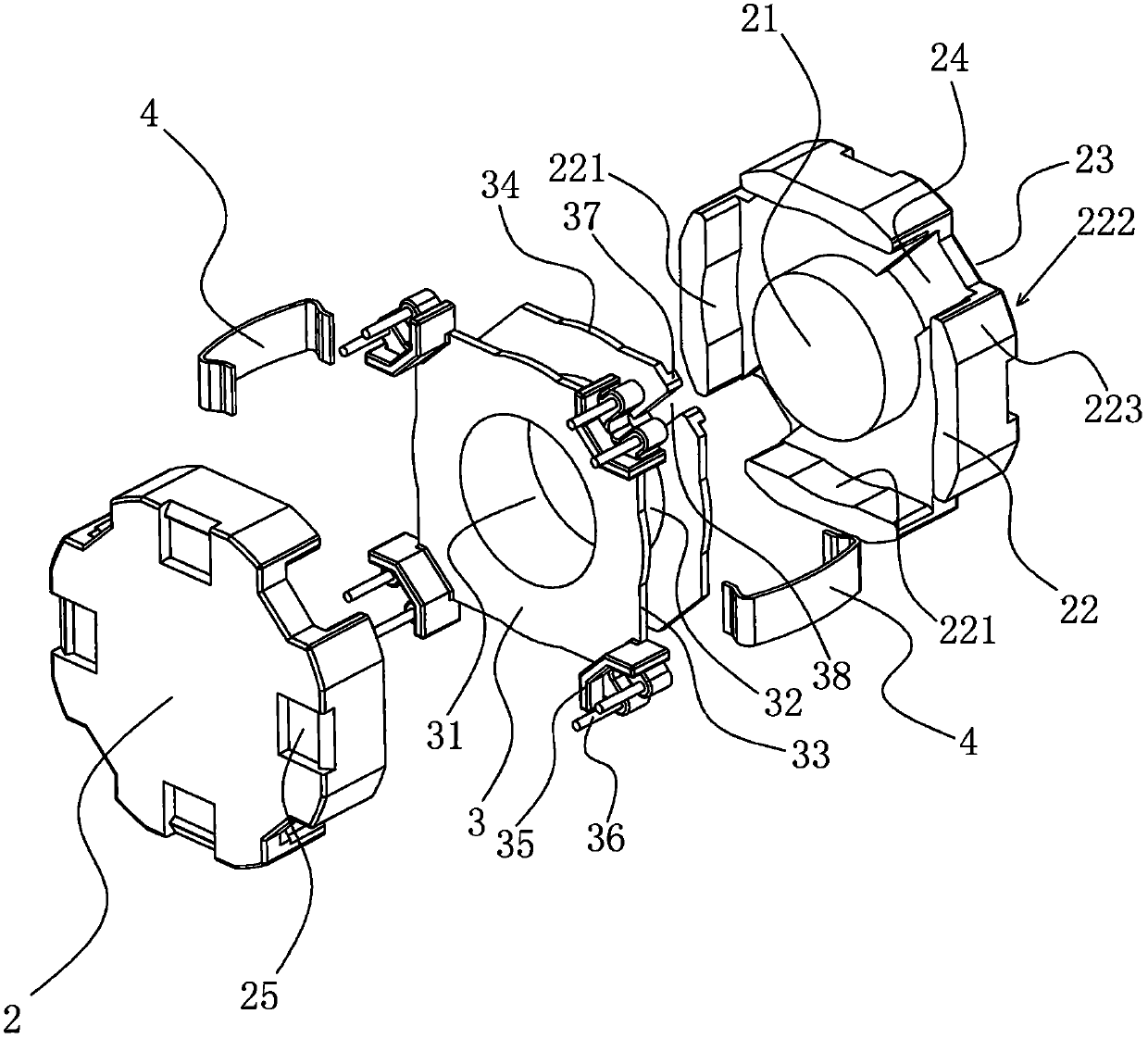

[0025] refer to Figure 1-Figure 5 , a PFC inductor of the present invention, including a magnetic core 1 formed by symmetrically combining two square bases 2, a winding skeleton 3 and a winding group nested on the magnetic core 1;

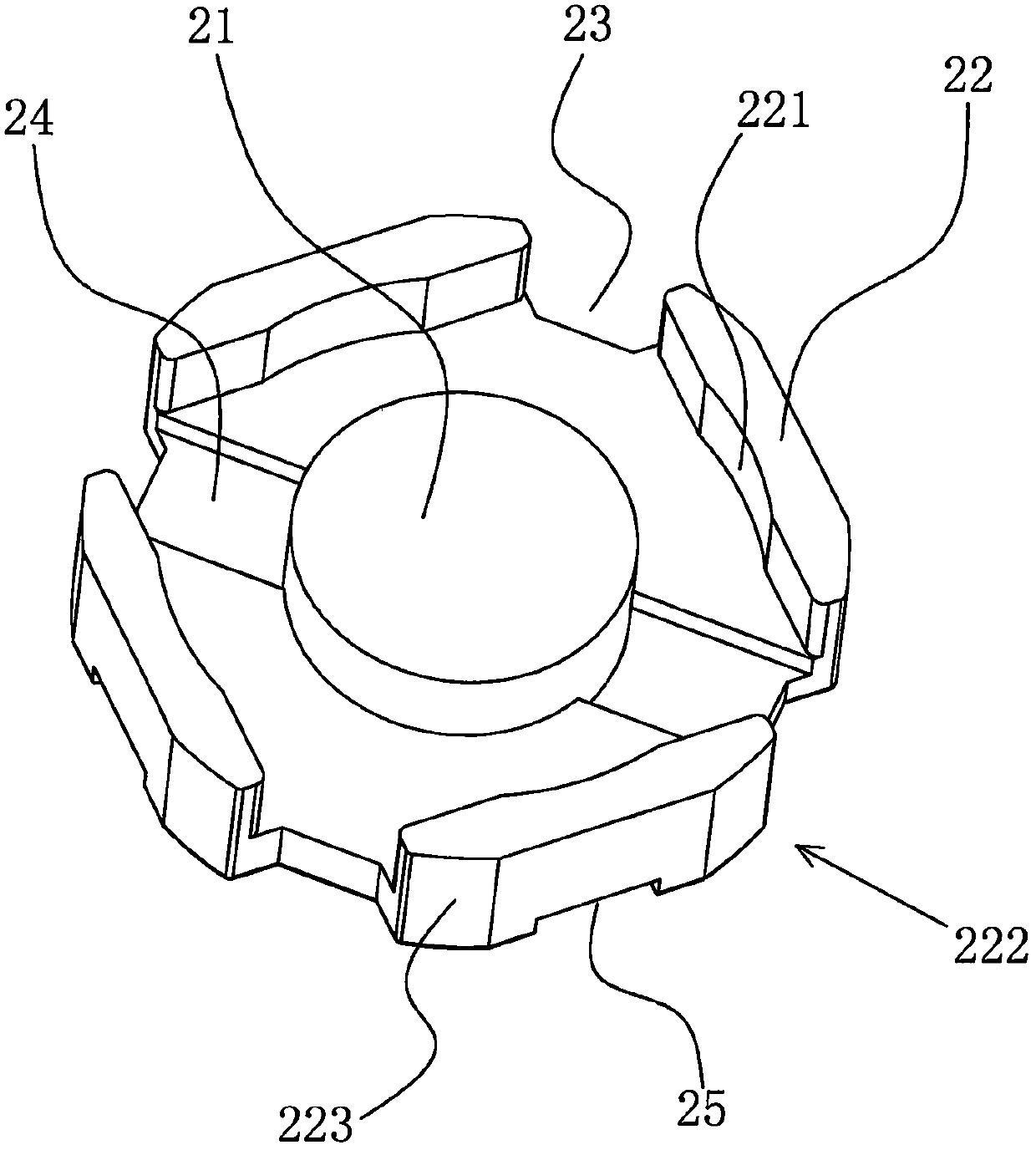

[0026] The base 2 includes a main core 21, which is cylindrical; a plurality of side wings 22 are arranged around the base 2, and slots 23 are arranged between adjacent side wings 22;

[0027] The winding frame 3 is provided with a perforation 31 having approximately the same shape as the main core portion 21, the perforation 31 is installed on the main core portion 21, and the winding frame 3 is installed on the gap between the main core portion 21 and the side wing portion 22. In the gap, the middle part of the winding skeleton 3 is a circular winding shaft 32, and the winding group is wound on the circular winding shaft 32 (not shown in the figure), adopting a cylindrical main core 21 whose cross section The winding method with a larger area a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com