Low-pressure SCR system and method for controlling same

A technology of SCR system and SCR reactor, which is applied to the electric control of exhaust treatment devices, exhaust treatment, mechanical equipment, etc., can solve the problems of increasing operating costs, wasting energy, increasing operating costs, etc., and achieves precise control and small size, effect of effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

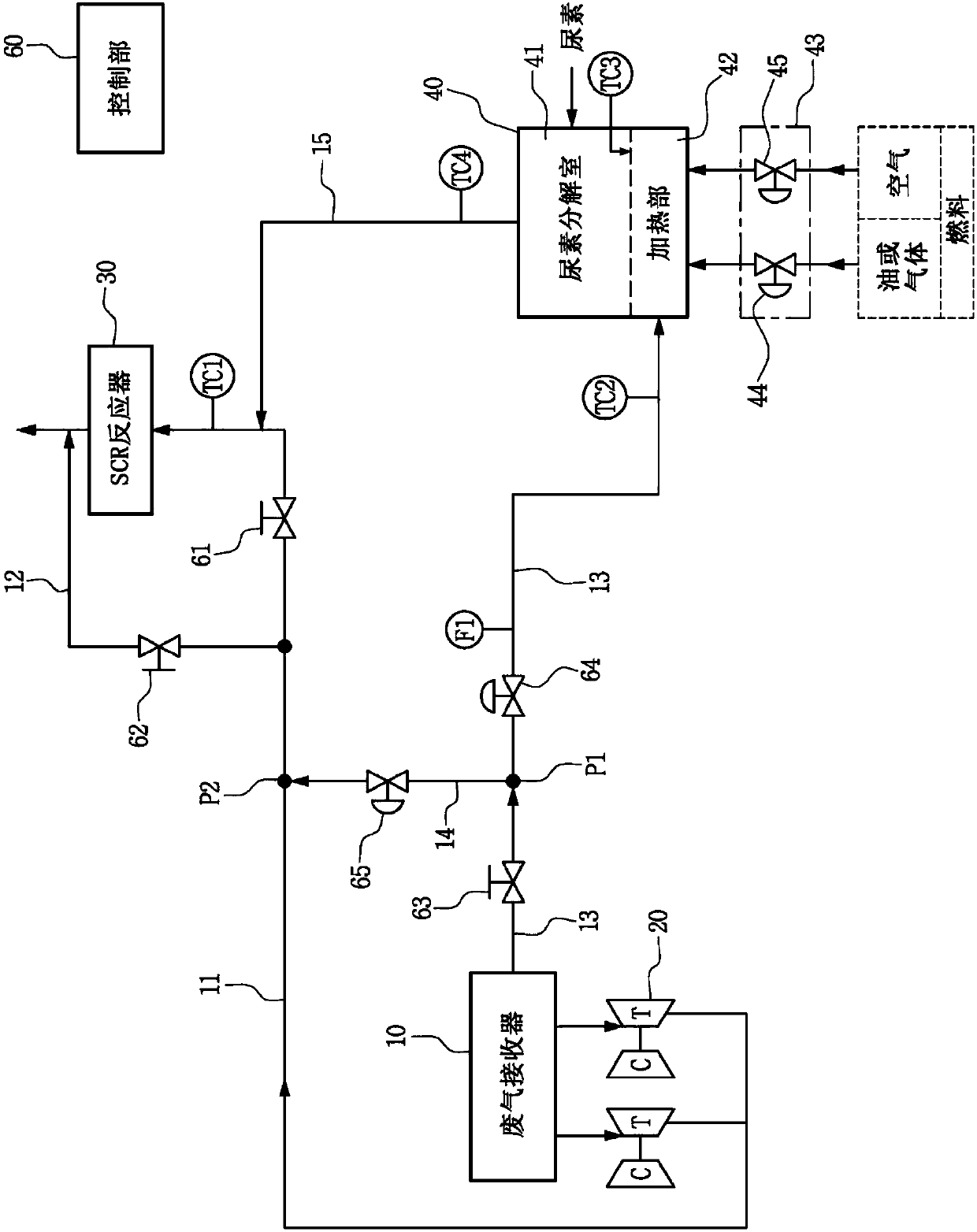

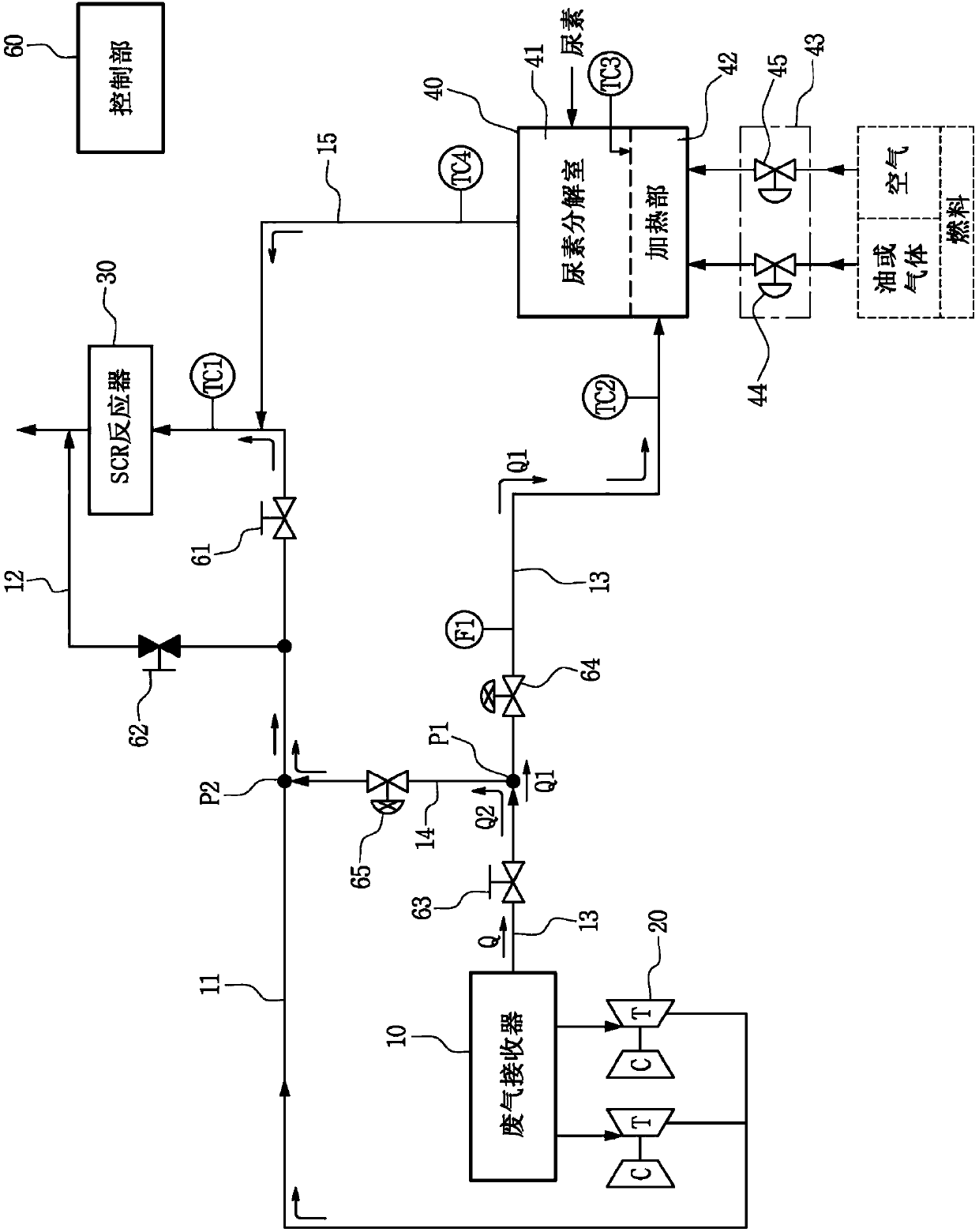

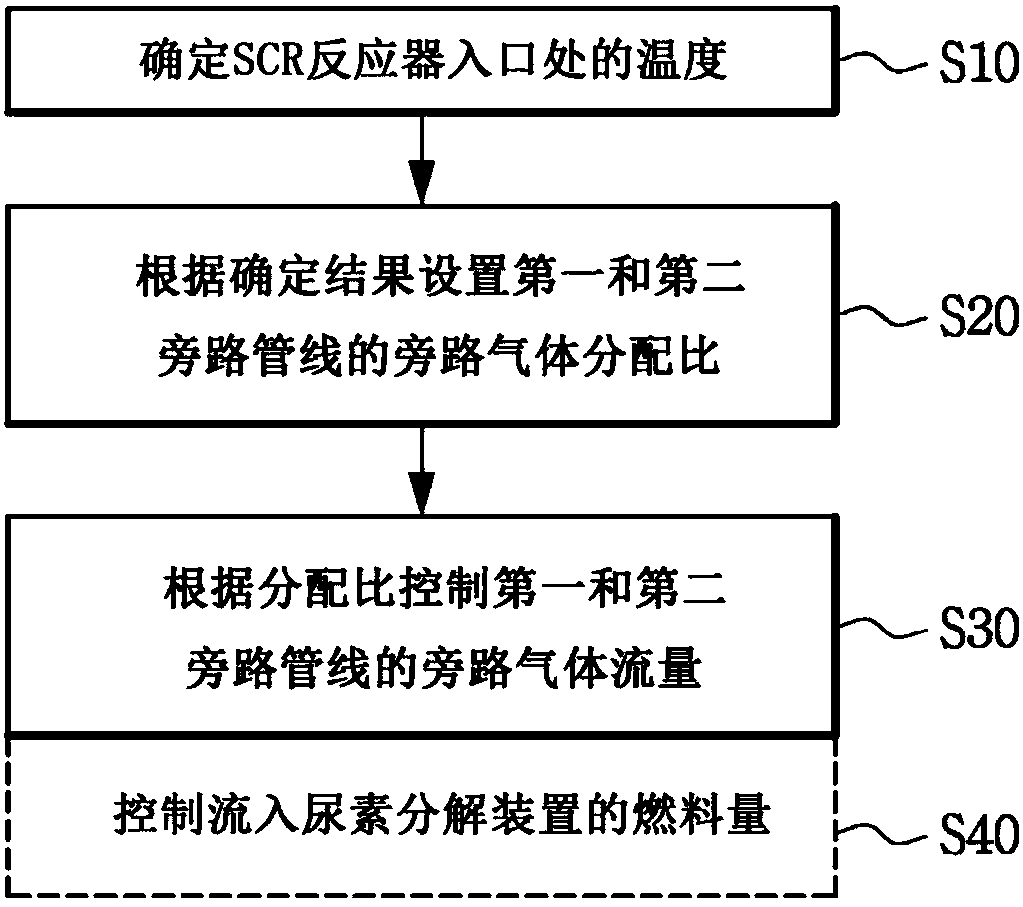

[0055] Hereinafter, a low voltage SCR system and a control method thereof according to an embodiment of the present disclosure will be described in detail with reference to the accompanying drawings. In the following description and claims, the term "SCR target temperature" is the lower limit of the temperature range in which the catalytic reaction for nitrogen oxide removal is normally initiated in the SCR reactor. Therefore, the temperature of the exhaust gas flowing into the SCR reactor should be kept above the "SCR target temperature". For example, if the temperature range for normally initiating a catalytic reaction is 250°C to 400°C, the SCR target temperature is 250°C, which is the lower limit of the above temperature range.

[0056] And, the term "target temperature of the heating gas" refers to the temperature or temperature range that the heating gas for urea decomposition entering the urea decomposition chamber should have. In other words, when the heating gas is k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com