Method of storing finally produced triethanolamine after preparation process of triethanolamine

A technology of triethanolamine and hydroxylamine, applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve problems such as the toxicity of triethanolamine, and achieve the effect of improving color and preventing discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

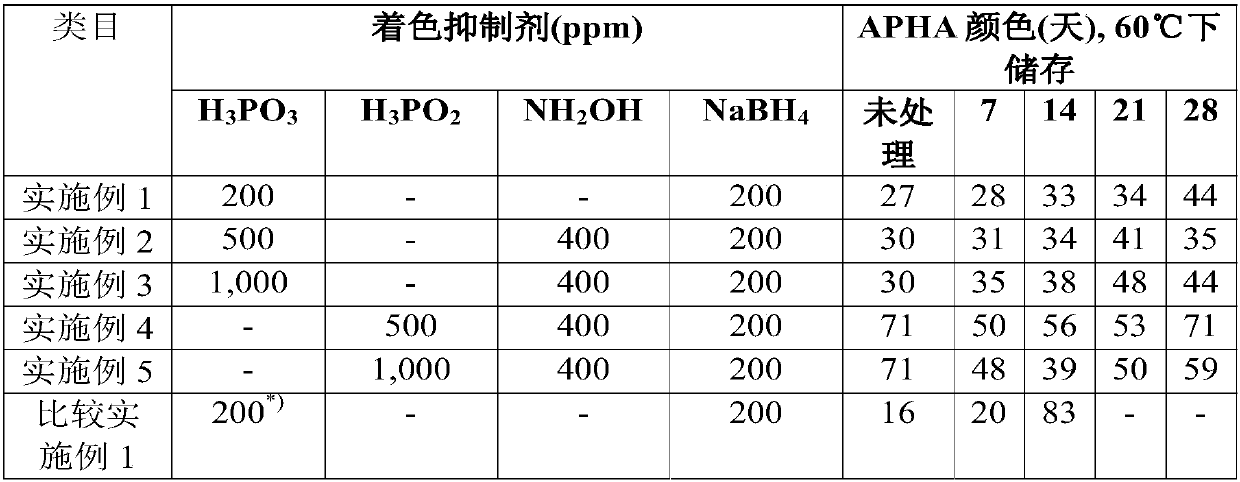

Embodiment 1

[0034] First, crude triethanolamine was prepared by a process comprising reacting ammonia with ethylene oxide in an aqueous medium at a molar ratio of 1:2 (ammonia:ethylene oxide) at 60° C. and atmospheric pressure. A mixture of crude triethanolamine, water and residue unreacted with ammonia is obtained and the water and ammonia are separated from crude triethanolamine using a distillation column arranged in series connecting said mixture to a crude triethanolamine separation step. Then, in order to continuously connect said crude triethanolamine free of water and ammonia to purification, ethanolamine, diethanolamine and ethoxylated triethanolamine are sequentially separated from triethanolamine by distillation of three distillation columns arranged in series to obtain Preparation of purified triethanolamine. Then, before the purified triethanolamine becomes discolored, quantify 200 ppm of phosphorous acid (using a 50% aqueous solution relative to the amount of phosphorous aci...

Embodiment 2

[0036] The experiment was carried out in the same manner as in Example 1, except that phosphorous acid (500 ppm), sodium borohydride (400 ppm) and hydroxylamine (200 ppm; a 50% aqueous solution relative to the amount of hydroxylamine was used) were treated in Example 1.

Embodiment 3

[0038] Experiments were performed in the same manner as in Example 1, except that phosphorous acid (1,000 ppm), sodium borohydride (400 ppm) and hydroxylamine (200 ppm) in Example 1 were treated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com