Raw material composition for anti-slip high-temperature-resistant plastic woven bag

A technology of plastic woven bags and high temperature resistance, applied in the field of plastic woven bags, can solve the problems of easy slippage, low service life, poor high temperature resistance, etc., and achieve the effects of increasing friction coefficient, prolonging service life and increasing softening temperature

Inactive Publication Date: 2018-03-16

TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Due to the advantages of light weight, high strength, and acid and alkali corrosion resistance, plastic woven bags are widely used in fertilizers, packaging and other fields. At present, commonly used plastic woven bags have poor high temperature resistance and low service life in summer high temperature environments. , In addition, plastic woven bags have the problem of slipping easily due to their smooth surface during the stacking process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

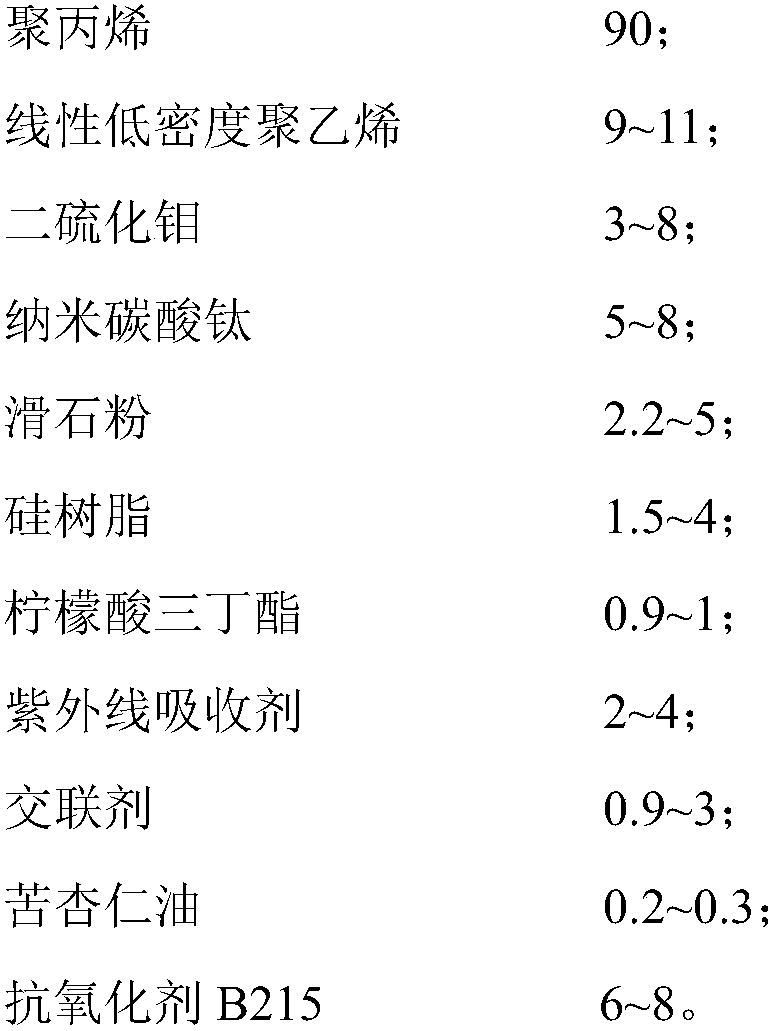

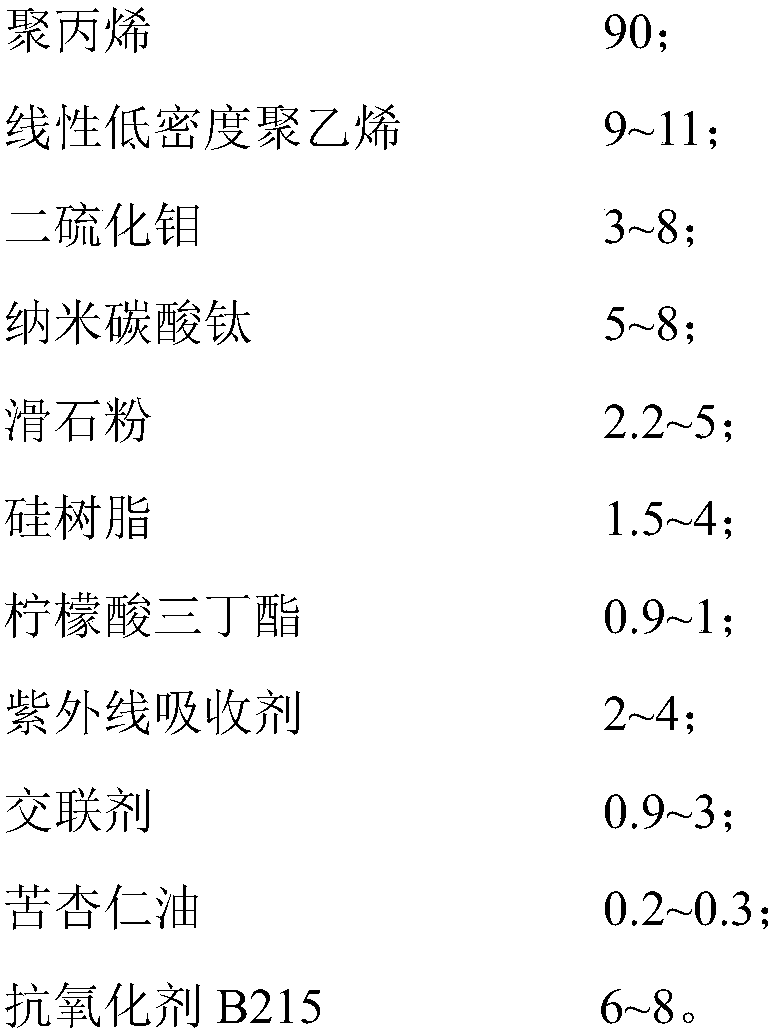

[0011] A raw material formula for an anti-slip and high-temperature resistant plastic woven bag, which consists of the following raw materials in parts by weight:

[0012]

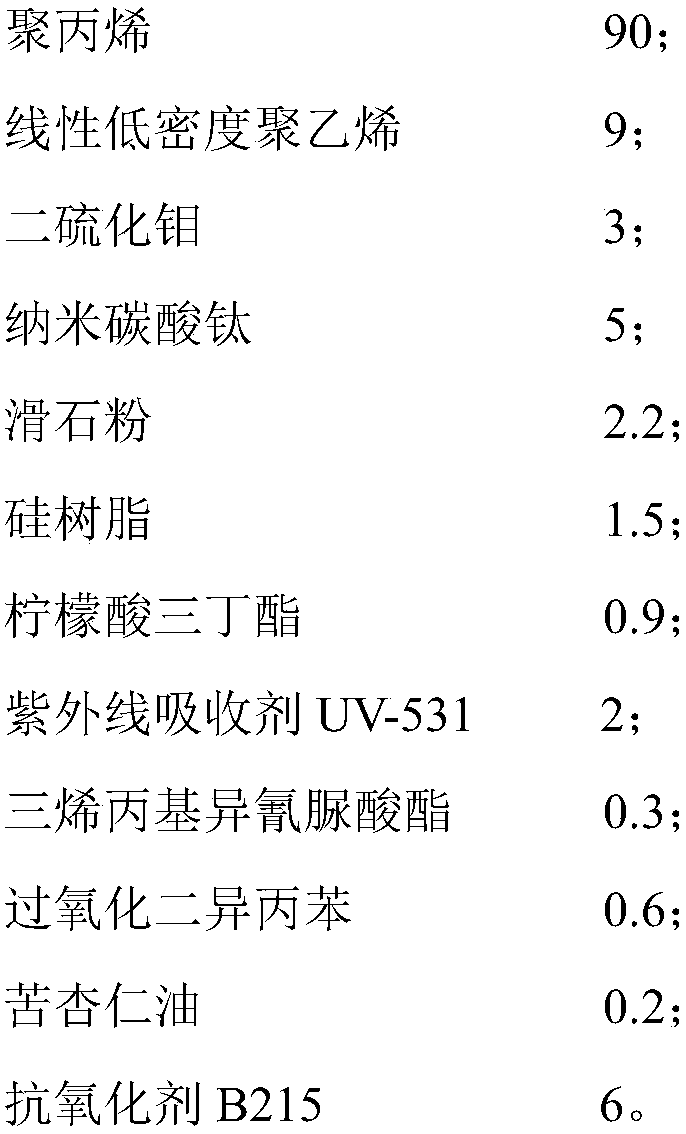

Embodiment 2

[0014] A raw material formula for an anti-slip and high-temperature resistant plastic woven bag, which consists of the following raw materials in parts by weight:

[0015]

[0016]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a raw material formula for an anti-slip and high-temperature resistant plastic woven bag, which consists of the following raw materials in parts by weight: 90 parts of polypropylene; 9-11 parts of linear low-density polyethylene; 3-8 parts of molybdenum disulfide; Nano-titanium carbonate is 5-8 parts; talcum powder is 2.2-5 parts; silicone resin is 1.5-4 parts; tributyl citrate is 0.9-1 part; ~3 parts; bitter almond oil 0.2~0.3 parts; antioxidant B215 6~8 parts. The invention provides a raw material formula for non-slip and high-temperature resistant plastic woven bags. By adding nano-titanium carbonate, talcum powder and silicone resin, under the action of a crosslinking agent, the softening temperature of the plastic woven bag is improved, and the plastic woven bag is effectively extended. The service life in the high temperature environment in summer, by adding molybdenum disulfide to increase the friction coefficient between the plastic woven bags, solves the problem that the plastic woven bags are easy to slip during the stacking process.

Description

technical field [0001] The invention relates to the technical field of plastic woven bags, in particular to a raw material formula for non-slip and high-temperature resistant plastic woven bags. Background technique [0002] Due to the advantages of light weight, high strength, and acid and alkali corrosion resistance, plastic woven bags are widely used in fertilizers, packaging and other fields. At present, commonly used plastic woven bags have poor high temperature resistance and low service life in summer high temperature environments. , In addition, plastic woven bags have the problem of easy slipping due to their smooth surface during stacking. Contents of the invention [0003] The invention aims to solve the deficiencies of the prior art, and provides a raw material formula for an anti-slip and high-temperature resistant plastic woven bag. [0004] In order to achieve the above object, the present invention adopts the following technical scheme: a raw material form...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/12C08L23/08C08L83/04C08L91/00C08K13/02C08K3/30C08K3/26C08K3/34C08K5/11C08K5/132D01F6/46D01F1/10

CPCC08L23/12C08L2201/08C08L2203/12C08L2205/02C08L2205/035D01F1/10D01F6/46C08L23/0815C08L83/04C08L91/00C08K13/02C08K3/30C08K3/26C08K3/34C08K5/11C08K5/132

Inventor 王旭辉

Owner TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com