Elastic electric contact composite material capable of replacing beryllium copper and preparation method thereof

A composite material and electrical contact technology, applied in electronic equipment, chemical instruments and methods, metal rolling, etc., can solve problems such as inability to meet the production requirements of thin plate materials, poor mechanical properties of welding joint surfaces, and difficulty in controlling the rolling size and thickness , to achieve good economic use value, good elasticity, thermal stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

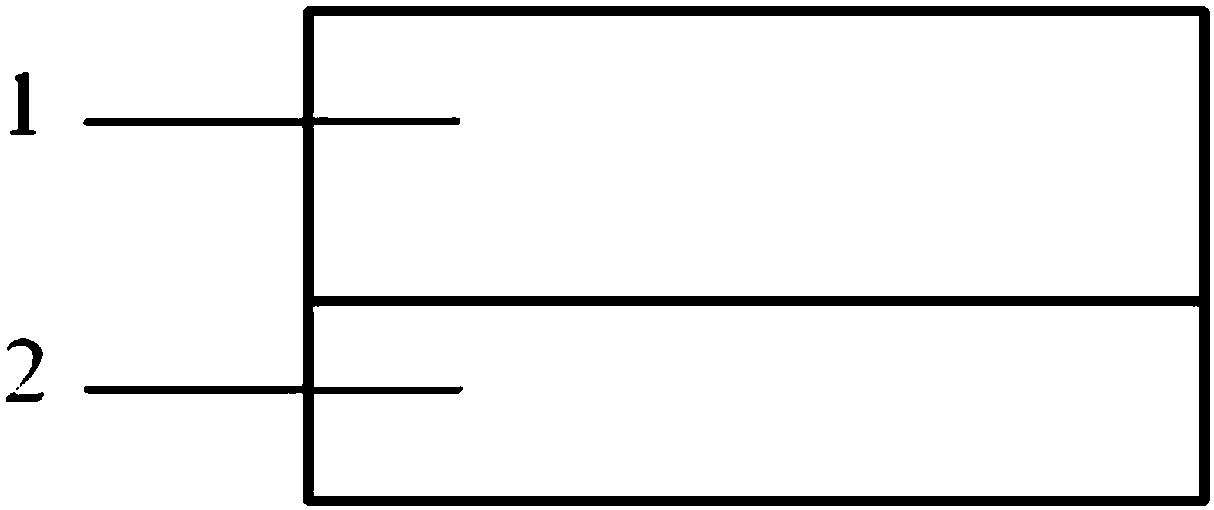

[0049] to prepare as figure 1 The two-layer elastic electrical contact composite material shown is an example, 1 is the 304 stainless steel layer, and the second is the Cu layer: the prepared elastic electrical contact composite material is made of stainless steel / Cu two-layer composite material tape, and the stainless steel in the two-layer composite material tape Layer thickness is 20-80% of the thickness of the entire composite strip;

[0050] Step 1: Composite rolling the 304 stainless steel strip and the Cu strip to prepare a 304 / Cu two-layer composite strip, using cold rolling composite, the strip width is 250mm, the rolling deformation is 60%, and the composite rate is 1.5m / min;

[0051] The second step: the 304 / Cu two-layer composite strip is subjected to diffusion heat treatment at a temperature of 875°C, using continuous annealing at a rate of 1.0m / min, and the atmosphere is H 2 , the gas flow rate is 3m 3 / h;

[0052] The third step: carry out three times (rolli...

Embodiment 2

[0058] to prepare as figure 1 The two-layer elastic electrical contact composite material shown is an example, 1 is 304 stainless steel, and 2 is Cu:

[0059] Step 1: Composite rolling the 304 stainless steel strip and the Cu strip to prepare a 304 / Cu two-layer composite strip, using cold rolling and compounding, the strip width is 400mm, the rolling deformation is 75%, and the composite rate is 3m / min;

[0060] The second step: the 304 / Cu two-layer composite strip is subjected to diffusion heat treatment at a temperature of 900°C, using continuous annealing at a rate of 2.0m / min, and the atmosphere is H 2 , the gas flow rate is 3m 3 / h;

[0061] The third step: carry out three times (rolling→softening heat treatment) cycle treatment on the compound strip after the above heat treatment, the rolling deformation of each cold rolling process before the cold rolling finished product is 35%, adopt softening heat treatment, the temperature is 1000 ℃, The speed is 2.5m / min, the a...

Embodiment 3

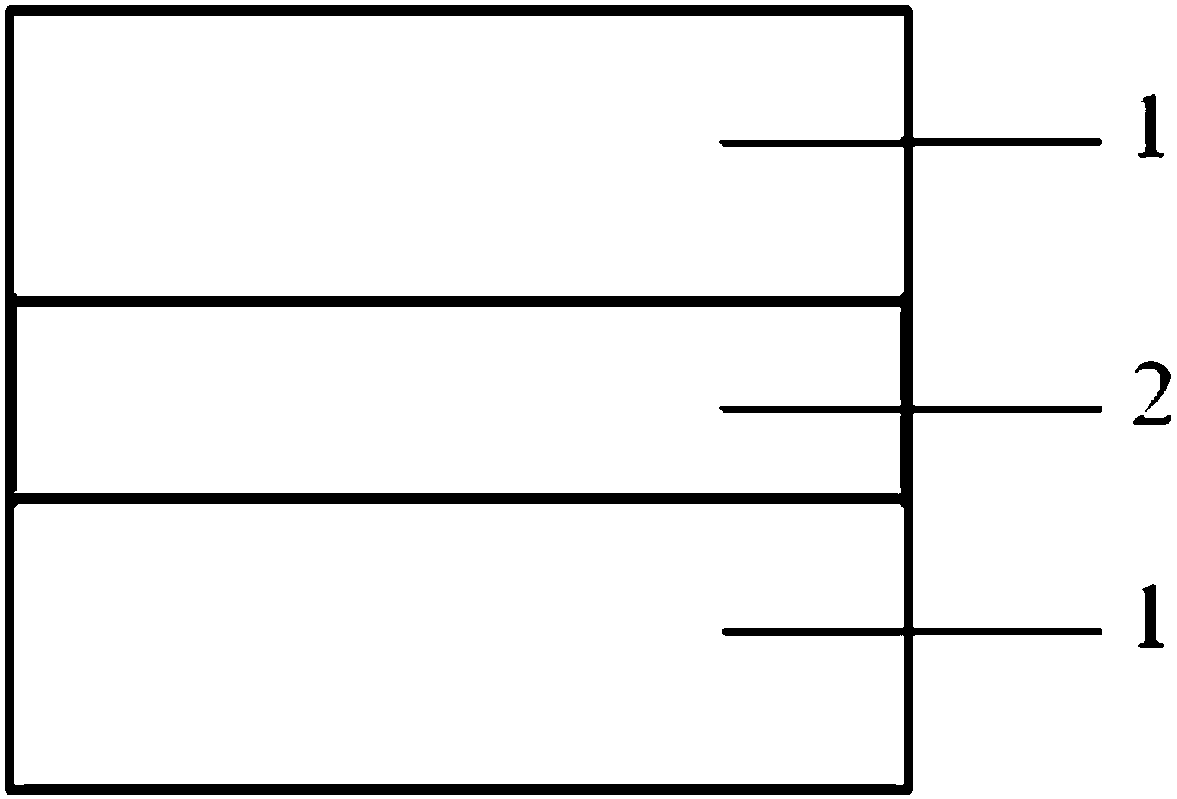

[0071] to prepare as figure 2 The three-layer elastic electrical contact composite material shown is an example, 1 is 301 stainless steel, and 2 is Cu: the prepared elastic electrical contact composite material is made of stainless steel / Cu / stainless steel three-layer composite material tape, and a single layer in the three-layer composite material tape The thickness of the side stainless steel layer is 20%-45% of the whole composite strip.

[0072] The first step: Composite rolling the 301 stainless steel strip and the Cu strip to prepare a 301 / Cu / 301 three-layer composite strip, using cold rolling composite, the width of the strip is 400mm, and the rolling deformation is 60%. The speed is 1.5m / min;

[0073] Step 2: Diffusion heat treatment of stainless steel / Cu / stainless steel three-layer composite strip at a temperature of 925°C, continuous annealing at a rate of 1.5m / min, and an atmosphere of H 2 , the gas flow rate is 3m 3 / h;

[0074] Step 3: Carry out four cycles o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com