Graphite dust treatment and recovery method based on double dust removal units

A recycling method and technology of graphite dust, applied in separation methods, chemical instruments and methods, loading/unloading, etc., can solve problems such as health threats to operators, pollution of workshop environment, difficult settling, etc., and achieve reasonable process design and convenient operation and maintenance. , The effect of high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

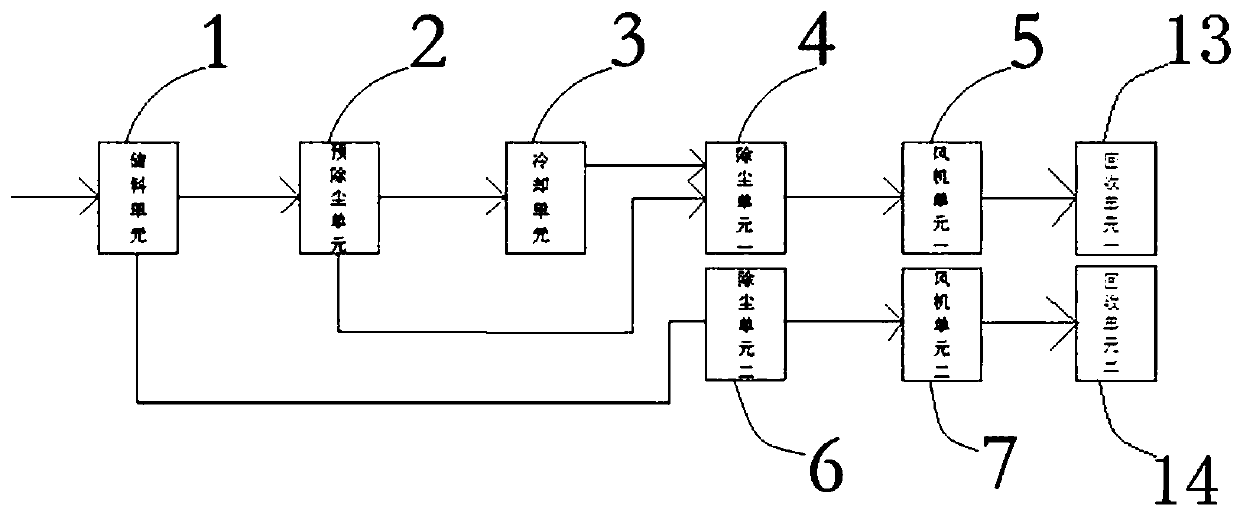

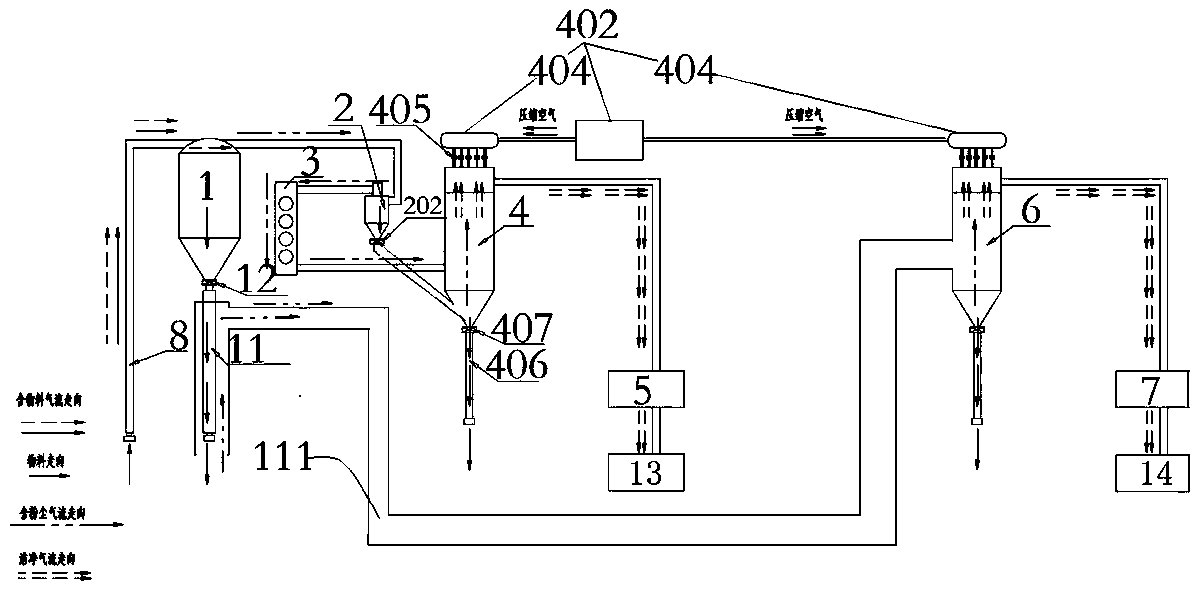

[0040] Such as Figure 1~6 As shown, a kind of graphite dust treatment recovery method based on double dedusting unit is provided in the present embodiment, comprising:

[0041] The fan unit-5 is set to provide conveying power, and the negative pressure air flow is generated to transport the high-temperature graphite powder through the storage unit 1, the pre-dust removal unit 2, the cooling unit 3 and the dust removal unit-4 in sequence;

[0042] The fan unit one 5 communicates with the output end of the dust removal unit one 4, and the pre-dust removal unit 2 communicates with the dust removal unit one 4;

[0043] A recovery unit one 13 is set, and the recovery unit one 13 communicates with the output end of the fan unit one 5;

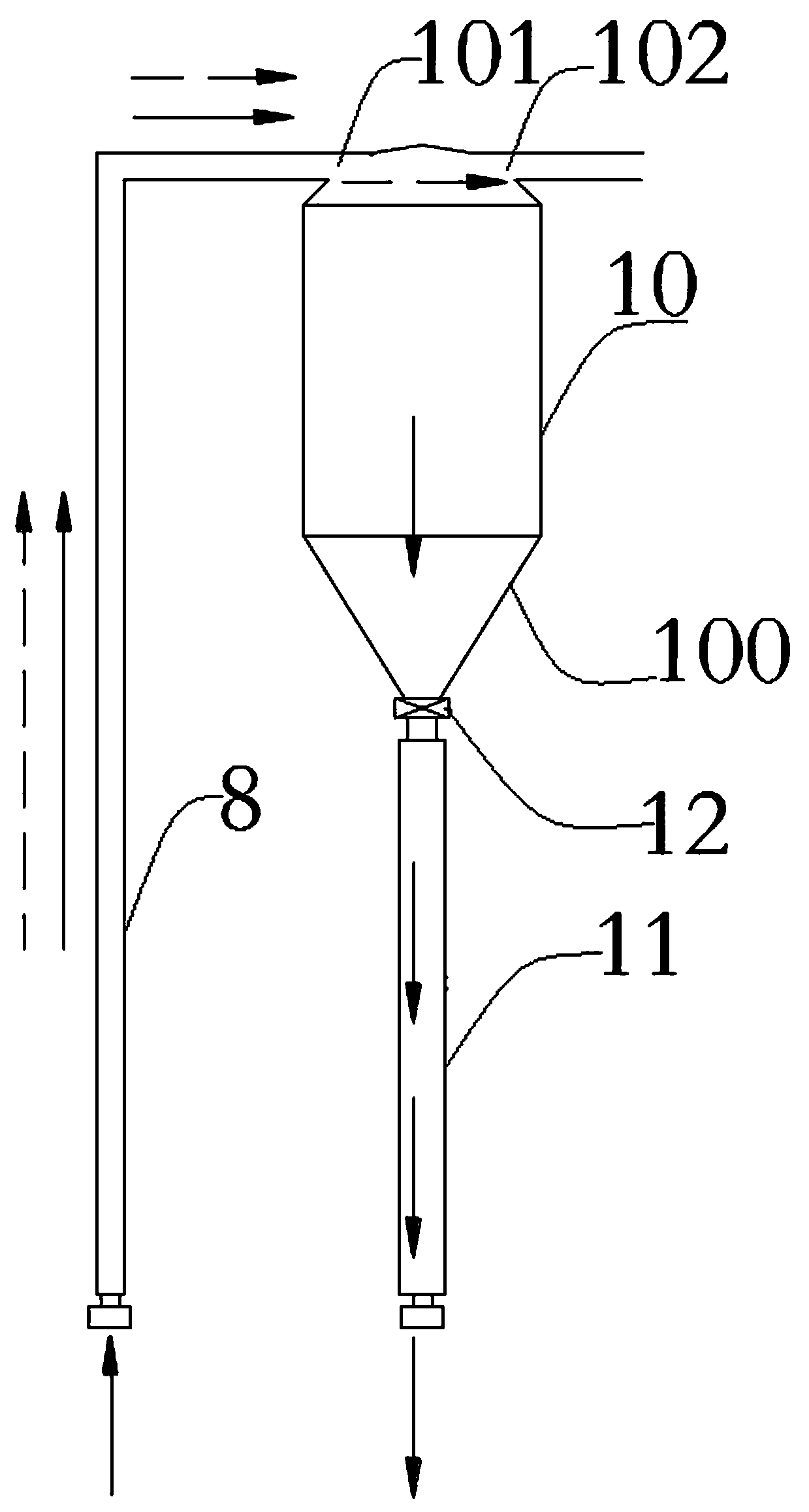

[0044] Set dust cover 110;

[0045] Set the fan unit 27 to provide dust removal power, generate negative pressure air flow to convey the dust in the graphite powder transportation and graphite powder unloading process through the dust cover 110 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com