Water-based paint spray mist agglutinant

A paint mist coagulant and water-based paint technology, which is applied in water/sewage treatment, adsorption water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of poor separation between water and paint, and achieve the goal of inhibiting bacterial growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

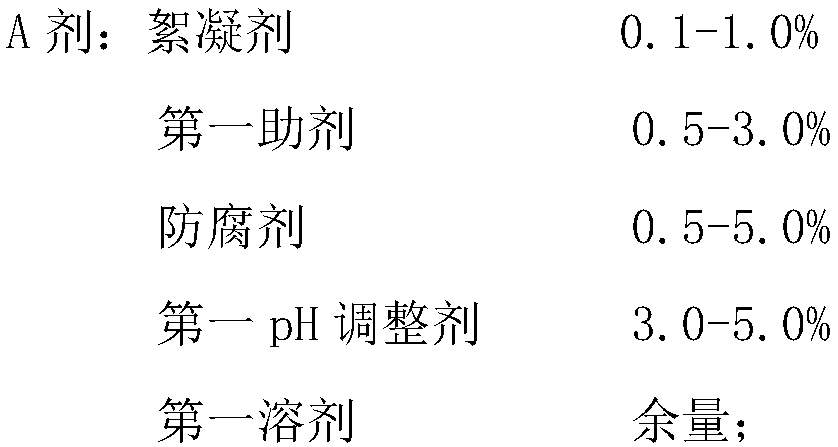

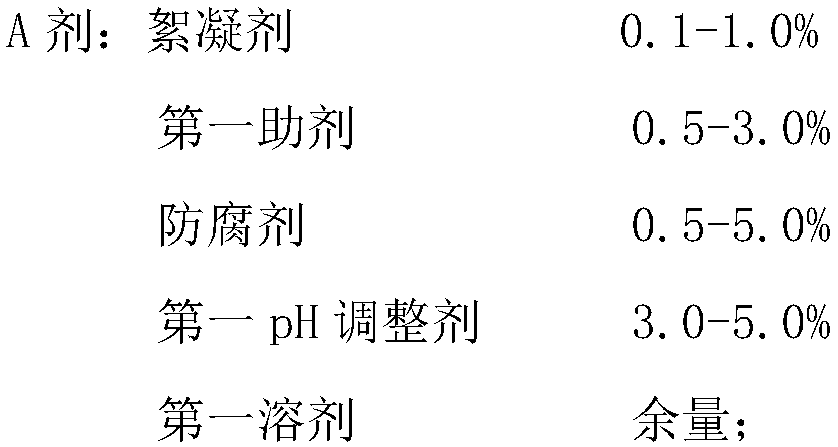

[0013] Agent A:

[0014] Step 1: Add 95.9 kg of deionized water into the reactor, and turn on the agitator provided in the reactor to stir;

[0015] Step 2: During the stirring process, add 3.0kg hydrochloric acid until the stirring is uniform;

[0016] Step 3: Add 0.5kg fungicide AH, and continue stirring until uniform;

[0017] Step 4: Then add 0.5kg of aluminum sulfate until there is no precipitation in the reaction, then slowly add 0.1kg of DMC-AM copolymer, and stir for about 3 hours until the mixture is uniform and free of particles.

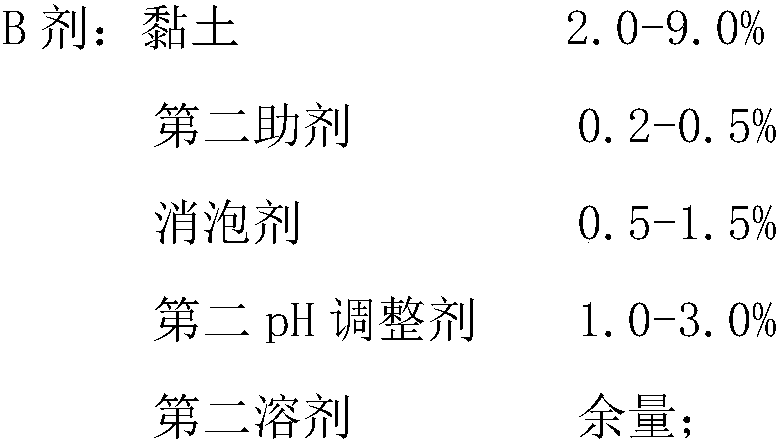

[0018] Agent B:

[0019] Step 1: Add 96.3kg of deionized water into the reactor, and turn on the agitator provided in the reactor to stir;

[0020] Step 2: In the process of stirring, add 1.0kg of sodium hydroxide to make it dissolve and wait for the temperature of the solution to drop to room temperature;

[0021] Step 3: Add 0.2kg of hydroxycellulose ether and continue to stir for 1-2 hours until the solution is uniform and free of p...

Embodiment 2

[0024] Agent A:

[0025] Step 1: Add 86kg of deionized water to the reactor, and turn on the agitator provided in the reactor to stir;

[0026] Step 2: During the stirring process, add 5.0kg hydrochloric acid until the stirring is uniform;

[0027] Step 3: Add 5.0kg fungicide AH again, and continue to stir until uniform;

[0028] Step 4: Then add 3.0kg of zinc sulfate until there is no precipitation in the reaction, then slowly add 1.0kg of polydimethyldipropylenepropylammonium chloride, and stir for about 3 hours until the mixture is uniform and free of particles.

[0029] Agent B:

[0030] Step 1: Add 86kg of deionized water to the reactor, and turn on the agitator provided in the reactor to stir;

[0031] Step 2: In the process of stirring, add 3.0kg of sodium hydroxide to make it dissolve and wait for the temperature of the solution to drop to room temperature;

[0032] Step 3: Add 0.5kg of hydroxycellulose ether and continue to stir for 1-2 hours until the solution is...

Embodiment 3

[0035] Agent A:

[0036] Step 1: Add 90.5kg of deionized water into the reactor, and turn on the agitator provided in the reactor to stir;

[0037] Step 2: In the process of stirring, add 4.0kg of sulfuric acid until the stirring is uniform;

[0038] Step 3: Add 3.0kg of BIT20 and continue stirring until uniform;

[0039] Step 4: Then add 2.0kg of zinc chloride until there is no precipitation in the reaction, then slowly add 0.5kg of dicyandiamide-formaldehyde cationic flocculant, and stir for about 3 hours until the mixture is uniform and free of particles.

[0040] Agent B:

[0041] Step 1: Add 91.15kg of deionized water into the reactor, and turn on the agitator provided in the reactor to stir;

[0042] Step 2: In the process of stirring, add 2.0kg potassium hydroxide to make it dissolve and wait for the temperature of the solution to drop to room temperature;

[0043] Step 3: Add 0.35kg of hydroxycellulose ether and continue to stir for 1-2 hours until the solution is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com