Additive-free normal-temperature yoghourt and preparation method thereof

An additive-free, yoghurt technology, applied in milk preparations, dairy products, applications, etc., can solve problems such as shortening product ingredients, and achieve the effects of high uniformity, stable product properties, and moderate viscosity and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Mix the non-antibiotic milk with sucrose, starch, and blueberry jam evenly after sterilizing at 135°C for 5s to obtain a mixed solution. The mixing ratio is as follows:

[0051] ingredients

Non-antibiotic milk after sterilization

blueberry jam

Addition wt%

88

8

2

2

[0052] The protein content in the raw milk in the above ingredients is 2.8wt%, the fat is 2.5wt%, the lactose content is 3.0wt%, the non-fat milk solid is 6.3wt%, and the titrated acidity is ≤18°T.

[0053] The modified starch corn or waxy corn used in the above ingredients is made by heat treatment and denaturation, and the starch particle size after denaturation is 5 μm.

[0054] The mixing temperature of the above ingredients is 50° C., the stirring speed is 300 rpm, and the stirring time is 5 minutes.

[0055] (2) Homogenize the mixed solution obtained in step (1) at 50° C., the pressure is 200 bar, and the starch granules aft...

Embodiment 2

[0062] (1) After sterilizing at 137°C for 3s, mix the non-antibiotic milk with sucrose and starch evenly to obtain a mixed solution. The ratio is as follows:

[0063] ingredients

Non-antibiotic milk after sterilization

sucrose

Addition wt%

95

4

1

[0064] The protein content in the raw milk in the above ingredients is 3.5wt%, the fat is 3.5wt%, the lactose content is 4.0wt%, the non-fat milk solid is 8.3wt%, and the titrated acidity is ≤18°T.

[0065] The modified starch in the above ingredients is made from cassava starch, which is denatured by microwaves, and the particle size of the starch after denaturation is 150 μm.

[0066] The mixing temperature of the above ingredients is 55° C., the stirring rate is 700 rpm, and the stirring time is 3 minutes.

[0067] (2) Homogenize the mixed solution obtained in step (1) at 55° C., the pressure is 150 bar, and the starch granules after homogenization are 150 μm;

[0068] (...

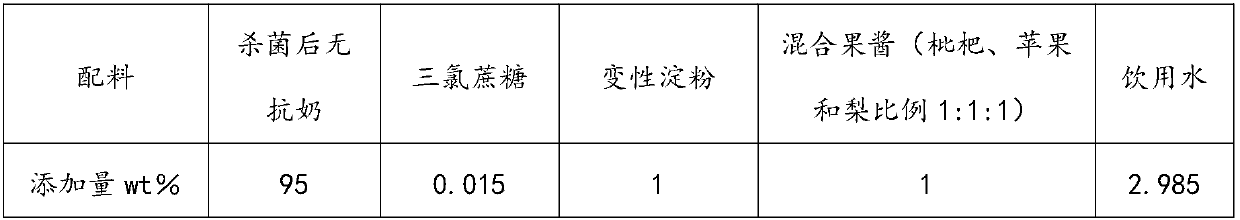

Embodiment 3

[0074] (1) Mix the non-antibiotic milk with aspartame, starch, drinking water and cranberry strawberry jam evenly after sterilizing at 136°C for 4s to obtain a mixed solution. The mixing ratio is as follows:

[0075] ingredients

Non-antibiotic milk after sterilization

modified starch

blueberry jam

drinking water

Addition wt%

81.94

0.005

2

2

7.995

[0076] The protein content in the raw milk in the above ingredients is 3.0wt%, the fat is 3.0wt%, the lactose content is 3.5wt%, the non-fat milk solid is 7.1wt%, and the titrated acidity is ≤18°T.

[0077] Among them, the modified starch is obtained by using potato starch as a raw material, which is denatured by ultrasonic treatment, and the particle size of the starch after denaturation is 100 μm.

[0078] The mixing temperature of the above ingredients is 53° C., the stirring speed is 500 rpm, and the stirring time is 4 minutes.

[0079] (2) Homogenize the mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com