Sprinkling liquid for tea leaves and application of sprinkling liquid

A technology for spraying liquid and tea, which is applied in the fields of application, tea, tea spices, etc. It can solve the problems of low content of thearubigins and theaflavins, insufficient oxidation of tea polyphenols, and insufficient fermentation of tea leaves, etc. Active, conducive to oxidation, and the effect of improving the flavor of tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

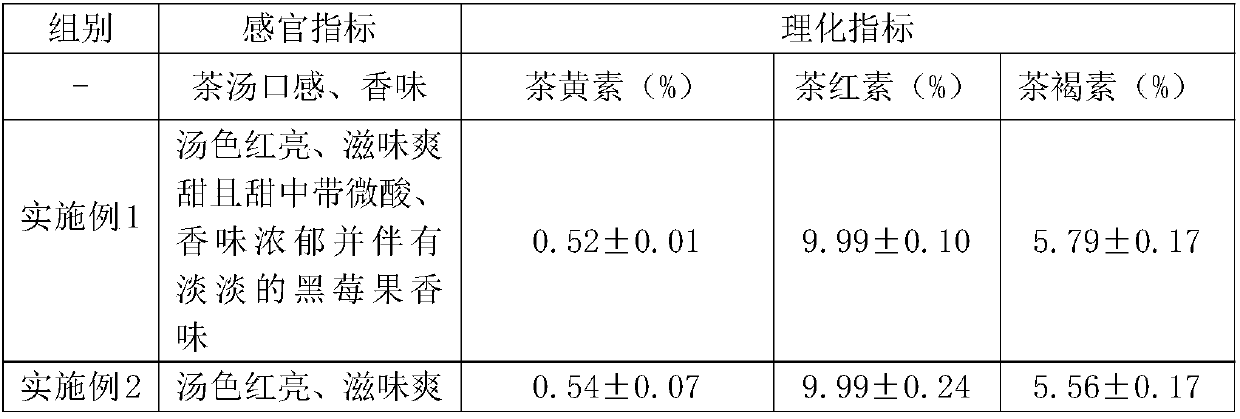

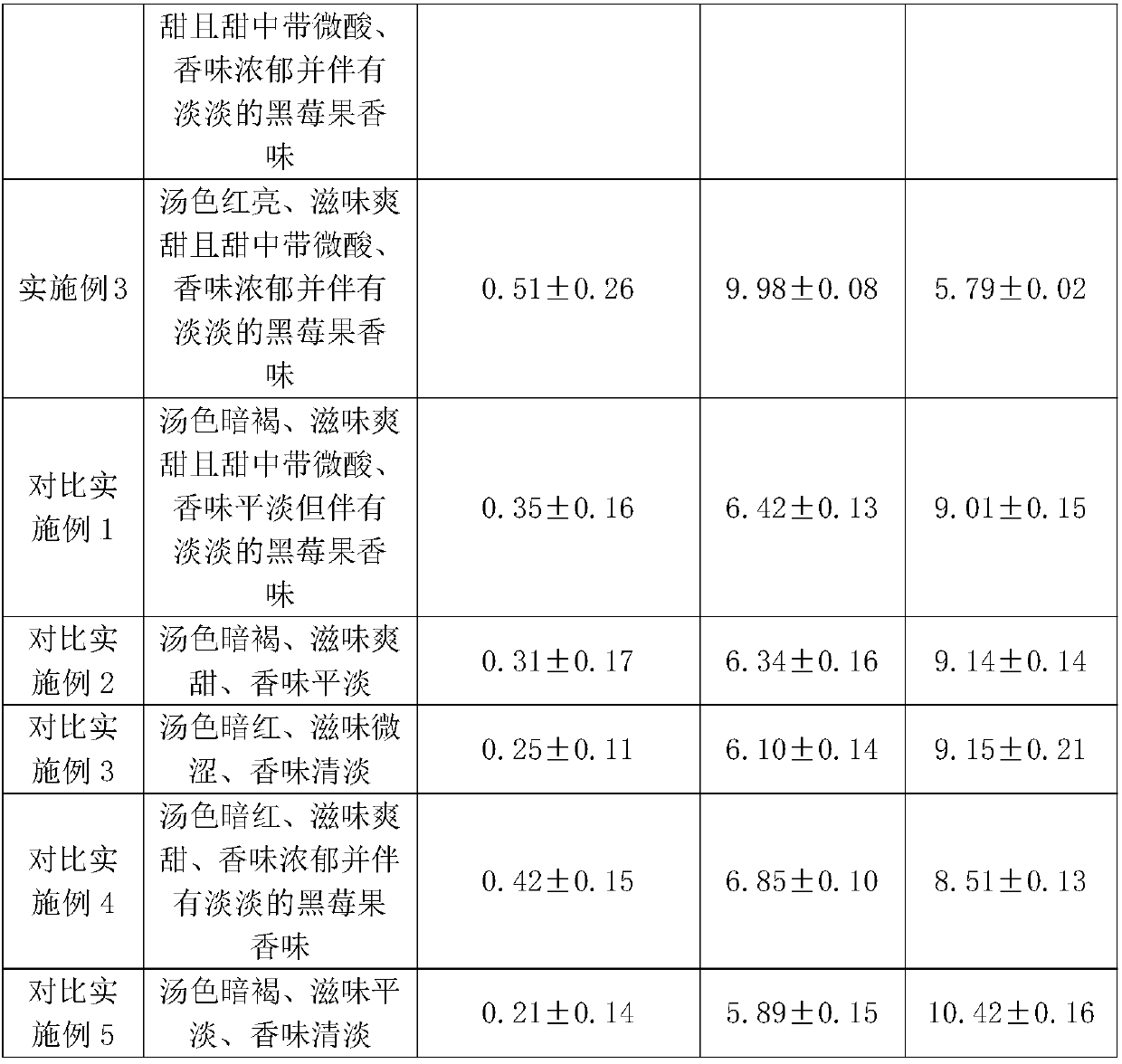

Examples

Embodiment 1

[0030] The preparation method of black tea comprises the following steps:

[0031] S1: Withering: Pick fresh tea leaves with one bud and one leaf or one bud and two leaves, soak the fresh tea leaves in 5% salt water for 30 minutes, then wash them with clean water, drain until there are no water drops on the leaves, and set aside; drain the fresh tea leaves The tea leaves are transported to the main machine of the withering machine, and the area of the fresh tea leaves is 30m 2 , with a thickness of 10cm, blown by a blower and withered;

[0032] The wind blown by the blower is cold wind and hot wind, and the order of the cold wind and hot wind blowing is to blow the cold wind first, and then blow the hot wind at an interval of 20 minutes; the temperature of the cold wind is 15°C, and the blowing time is 2.5h; the temperature of the hot wind is 30°C The blowing time is 5.5h;

[0033] S2: Kneading pretreatment: put the tea leaves withered in step S1 into a green shaking machi...

Embodiment 2

[0040] The preparation method of black tea comprises the following steps:

[0041] S1: Withering: Pick fresh tea leaves with one bud and one leaf or one bud and two leaves, soak the fresh tea leaves in 6.5% salt water for 25 minutes, then wash them with clean water, drain until there are no water drops on the leaves, and set aside; drain the fresh tea leaves The tea leaves are transported to the main machine of the withering machine, and the area of the fresh tea leaves is 33m 2 , with a thickness of 15cm, blown by a blower and withered;

[0042] The wind blown by the blower is cold air and hot air, and the order of the cold air and hot air blowing is to blow the cold air first, and then blow the hot air at an interval of 20 minutes; the temperature of the cold air is 16°C, and the blowing time is 2h; The time is 4h;

[0043] S2: Kneading pretreatment: put the tea leaves withered in step S1 into a shaker with a rotation speed of 100r / min and shake them for 40 minutes, and ...

Embodiment 3

[0050] The preparation method of black tea comprises the following steps:

[0051] S1: Withering: pick fresh tea leaves with one bud and one leaf, or one bud and two leaves, soak the fresh tea leaves in 8% salt water for 20 minutes, wash them with clean water, drain until there are no water drops on the leaves, and set aside; drain the fresh tea leaves The tea leaves are transported to the main machine of the withering machine, and the area of the fresh tea leaves is 36m 2 , with a thickness of 20cm, blown by a blower and withered;

[0052] The wind blown by the blower is cold wind and hot wind, and the order of the cold wind and hot wind blowing is to blow the cold wind first, and then blow the hot air at an interval of 20 minutes; the temperature of the cold wind is 18°C, and the blowing time is 1.5h; the temperature of the hot wind is 35°C The blowing time is 4.5h;

[0053] S2: Kneading pretreatment: put the tea leaves withered in step S1 into a shaker with a rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com