Apex head of honeycomb structure, endoscope and manufacturing method of apex head

A technology of honeycomb structure and endoscope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

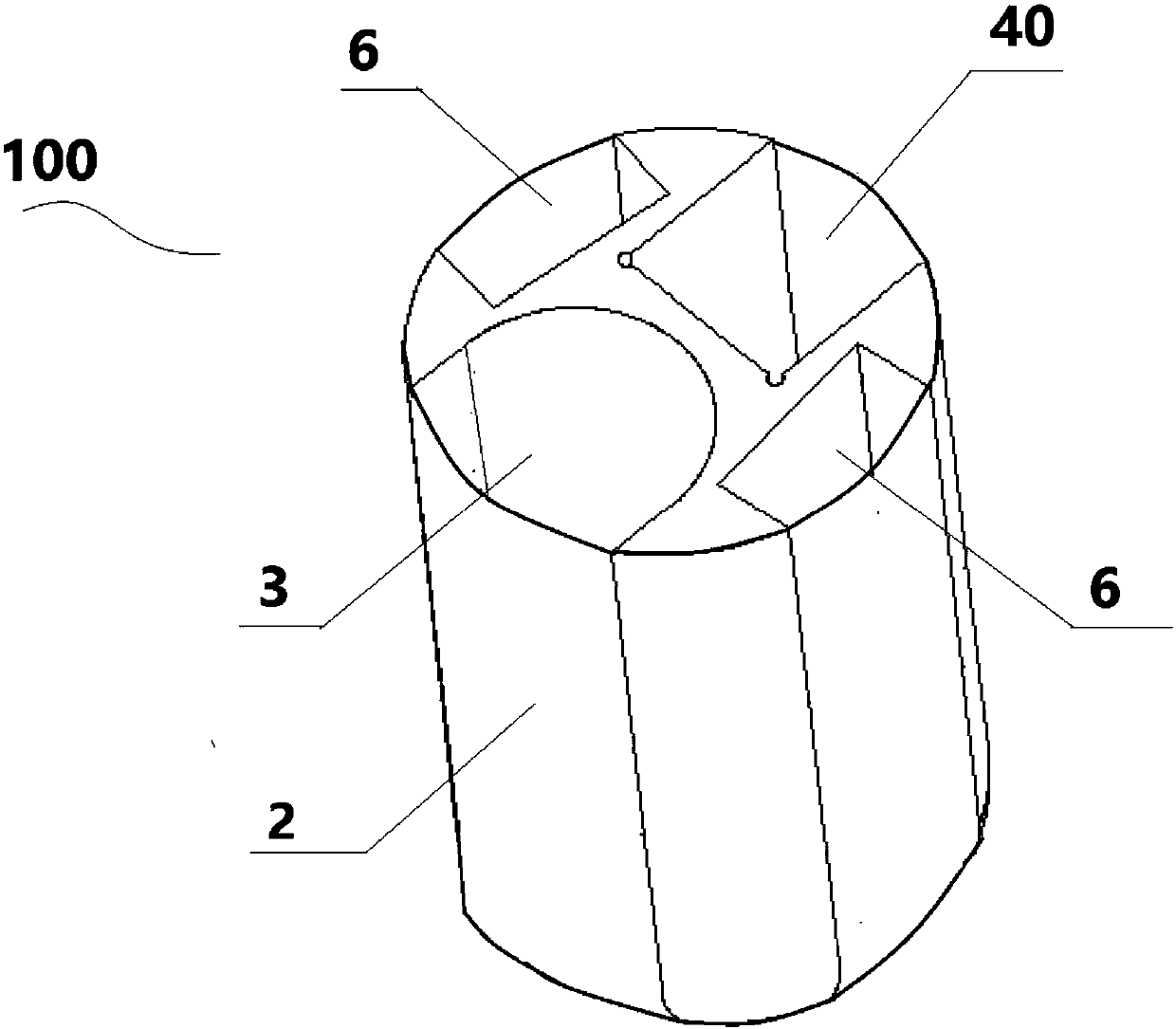

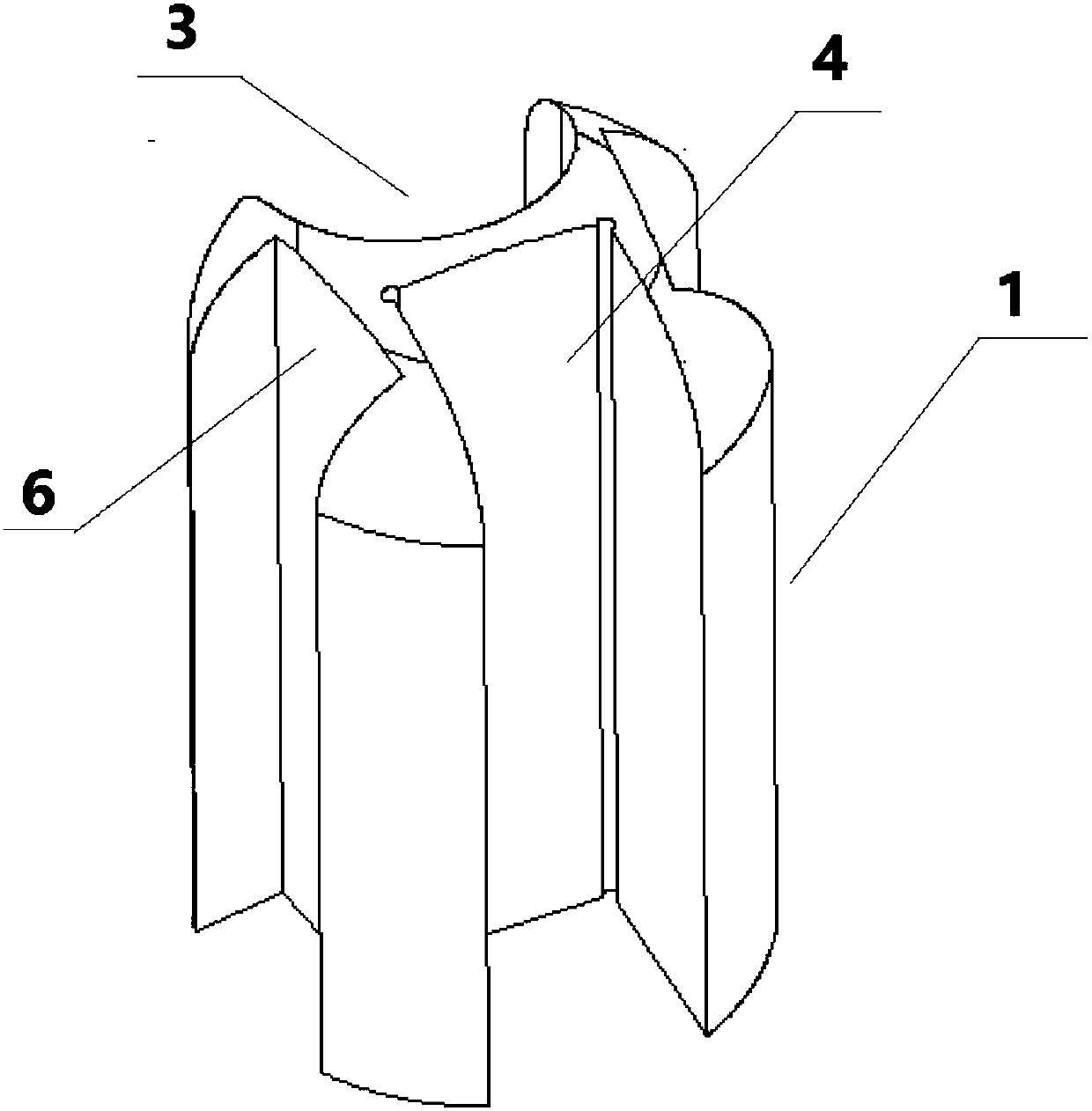

[0035] Such as Figure 1-1 to Figure 1-3 As shown, the first embodiment of the present invention discloses a tip head 100 with a honeycomb structure, which is installed on the front end of the catheter of the endoscope, including: a multi-channel module seat 1 and sleeved on the outer surface of the multi-channel module seat The sleeve 2, the multi-channel module seat 1 is a cylindrical irregular body structure with multiple concave channels on the outer surface of the circumference, and the sleeve 2 is hollow whose inner diameter matches the outer diameter of the irregular body structure. Cylinder, when the sleeve is sleeved on the peripheral surface of the multi-channel module base, multiple concave channels and the sleeve together form a plurality of closed channels with both ends open, and the multiple closed channels with both ends open at least include The instrument catheter installation channel 3 for inserting the instrument catheter and the camera module installation ...

no. 2 example

[0051] Such as Figure 4 As shown, this embodiment discloses an endoscope 200, which includes an insertion catheter 201 and an operation part 202 connected to the rear end of the catheter. The front end of the catheter 201 is equipped with a tip head 100 with a honeycomb structure. The tip head 100 includes: The channel module base 1 and the sleeve 2 sleeved on the outer surface of the multi-channel module base, the multi-channel module base 1 is a cylindrical irregular body structure with multiple concave channels on the outer surface of the circumference, the sleeve The cylinder 2 is a hollow cylinder whose inner diameter matches the outer diameter of the irregular body structure. When the sleeve is sleeved on the outer surface of the multi-channel module base, multiple concave channels and the sleeve together form a plurality of two channels. A closed channel with an open end, a plurality of closed channels with open ends at least include an instrument catheter installation...

no. 3 example

[0058] The third embodiment of the valve also discloses a method for manufacturing the tip head of the honeycomb structure, such as Figure 5 , including the following steps:

[0059] Step S301, using a cutting process to form a cylindrical irregular body structure with a plurality of concave channels on the outer surface of the circumference;

[0060] Step S302, using a cutting process to process the cylindrical pipe to form a hollow cylindrical sleeve whose inner diameter matches the outer diameter of the irregular body structure;

[0061] In step S303, the sleeve is sleeved on the outer surface of the irregular structure through a fixing process to form the apex head, and a plurality of concave channels and the sleeve together form a plurality of closed channels with openings at both ends, so that the apex head as a whole Has a honeycomb structure.

[0062] In this embodiment, the cylindrical irregular body structure may be cut from a cylindrical member, or may be cut fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com