Method for producing low-carbon olefin by synthetic gas

A low-carbon olefin and synthesis gas technology, applied in the direction of hydrocarbon production from carbon oxides, chemical instruments and methods, hydrocarbons, etc., can solve the problem of low selectivity of low-carbon olefins, and achieve high reaction space velocity and reaction temperature Easy to control and achieve beneficial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment provides a kind of bifunctional catalyst of synthesis gas directly producing light olefins, and the weight percent of its each component is: Fe 2 o 3 35%, MnO 6%, K 2 O 4%, Al 2 o 3 20%, ZSM-5 molecular sieve 35%, the silicon-aluminum ratio of ZSM-5 molecular sieve is 300.

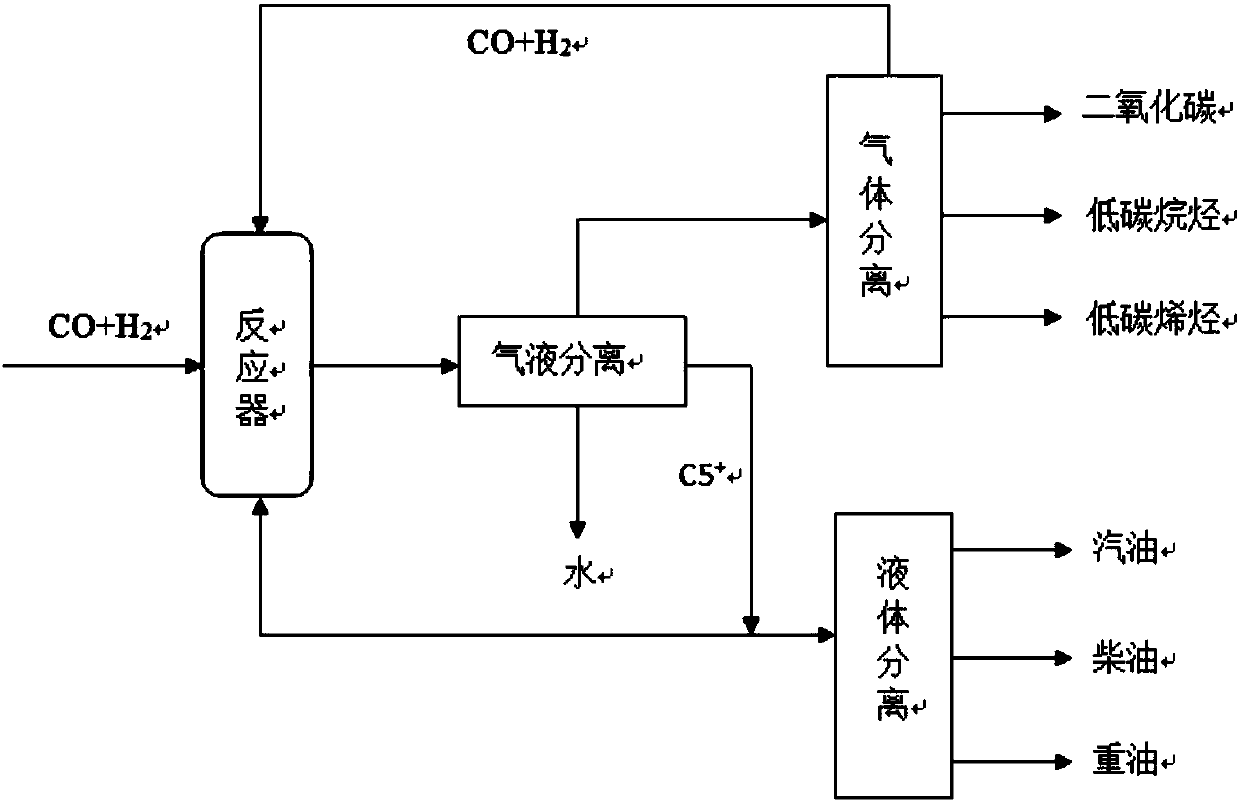

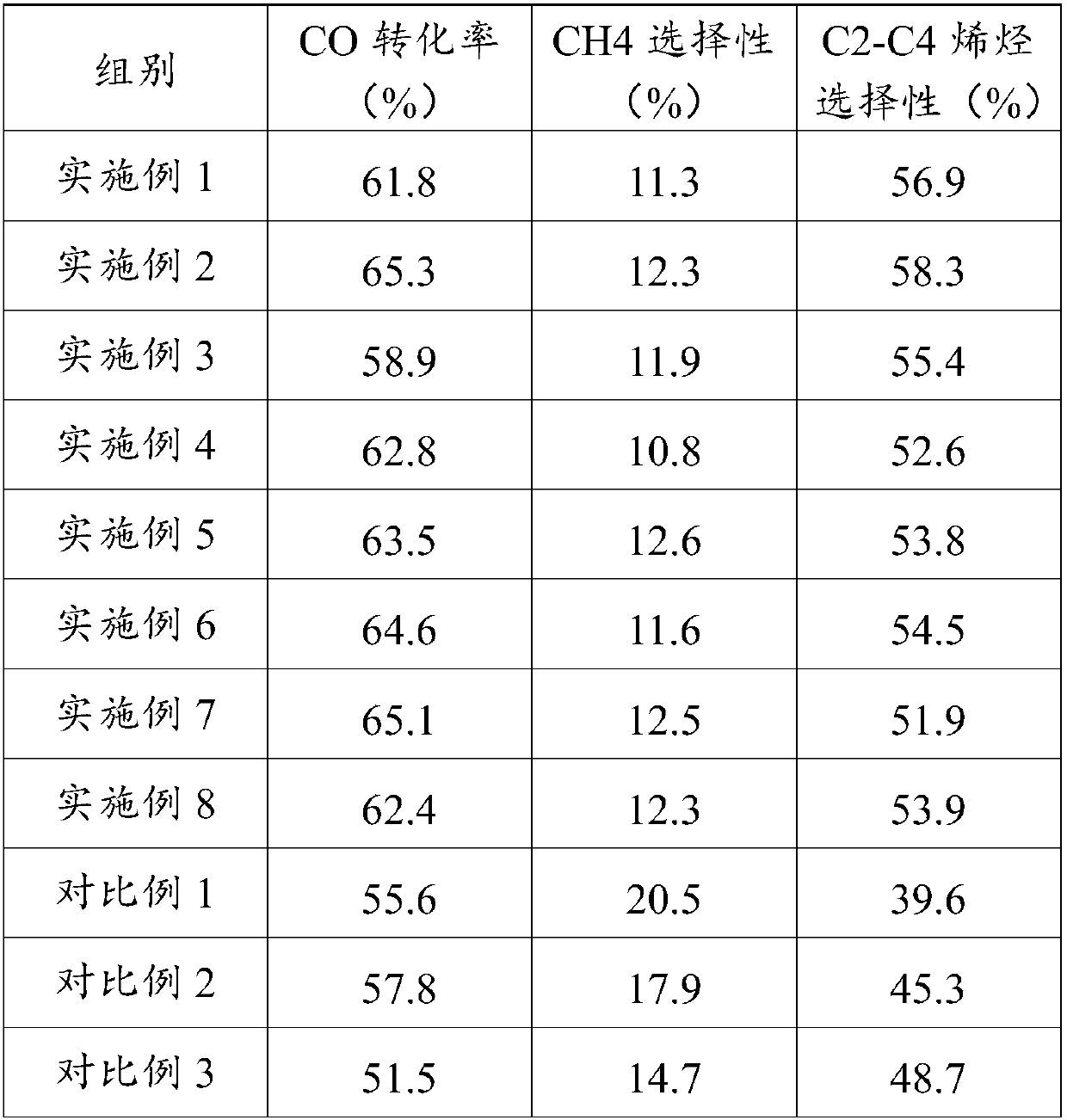

[0049] This embodiment also provides a process for directly producing low-carbon olefins from synthesis gas, the flow process of which is as follows figure 1 As shown, the process conditions are as follows: H in the syngas 2 The / CO volume ratio is 2, the reaction temperature is 320°C, the pressure is 0.5MPa, and the total space velocity of the raw material gas is 1000h -1 , the oil phase product C5 + 1 / 2 of the fraction was refined back, and the gas products were separated to obtain light olefins. The reaction results are shown in Table 1.

Embodiment 2

[0051] The present embodiment provides a kind of bifunctional catalyst of synthesis gas directly producing light olefins, and the weight percent of its each component is: Fe 2 o 3 35%, MnO 6%, K 2 O 4%, Al 2 o 3 20%, SPAO-34 molecular sieve 35%, the silicon-aluminum ratio of SPAO-34 molecular sieve is 0.1.

[0052] This embodiment also provides a process for directly producing low-carbon olefins from synthesis gas, the flow process of which is as follows figure 1 As shown, the process conditions are as follows: H in the syngas 2 The / CO volume ratio is 2, the reaction temperature is 320°C, the pressure is 0.5MPa, and the total space velocity of the raw material gas is 1000h -1 , the oil phase product C5 + 1 / 2 of the fraction was refined back, and the gas products were separated to obtain light olefins. The reaction results are shown in Table 1.

Embodiment 3

[0054] The present embodiment provides a kind of bifunctional catalyst of synthesis gas directly producing light olefins, and the weight percent of its each component is: Fe 2 o 3 35%, MnO 6%, K 2 O 4%, Al 2 o 3 20%, ZSM-5 molecular sieve 35%, the silicon-aluminum ratio of ZSM-5 molecular sieve is 100.

[0055] This embodiment also provides a process for directly producing low-carbon olefins from synthesis gas, the flow process of which is as follows figure 1 As shown, the process conditions are as follows: H in the syngas 2 The / CO volume ratio is 3, the reaction temperature is 350°C, the pressure is 1.0MPa, and the total space velocity of the raw material gas is 3000h -1 , the oil phase product C5 + 1 / 2 of the fraction was refined back, and the gas products were separated to obtain light olefins. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com