Rotatable lifting device for construction engineering

A kind of construction engineering, rotary technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of increasing the bearing load of the column, waste of resources, low flexibility, etc., to improve the structural stability and increase the operation. The effect of space and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order for those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and the following embodiments.

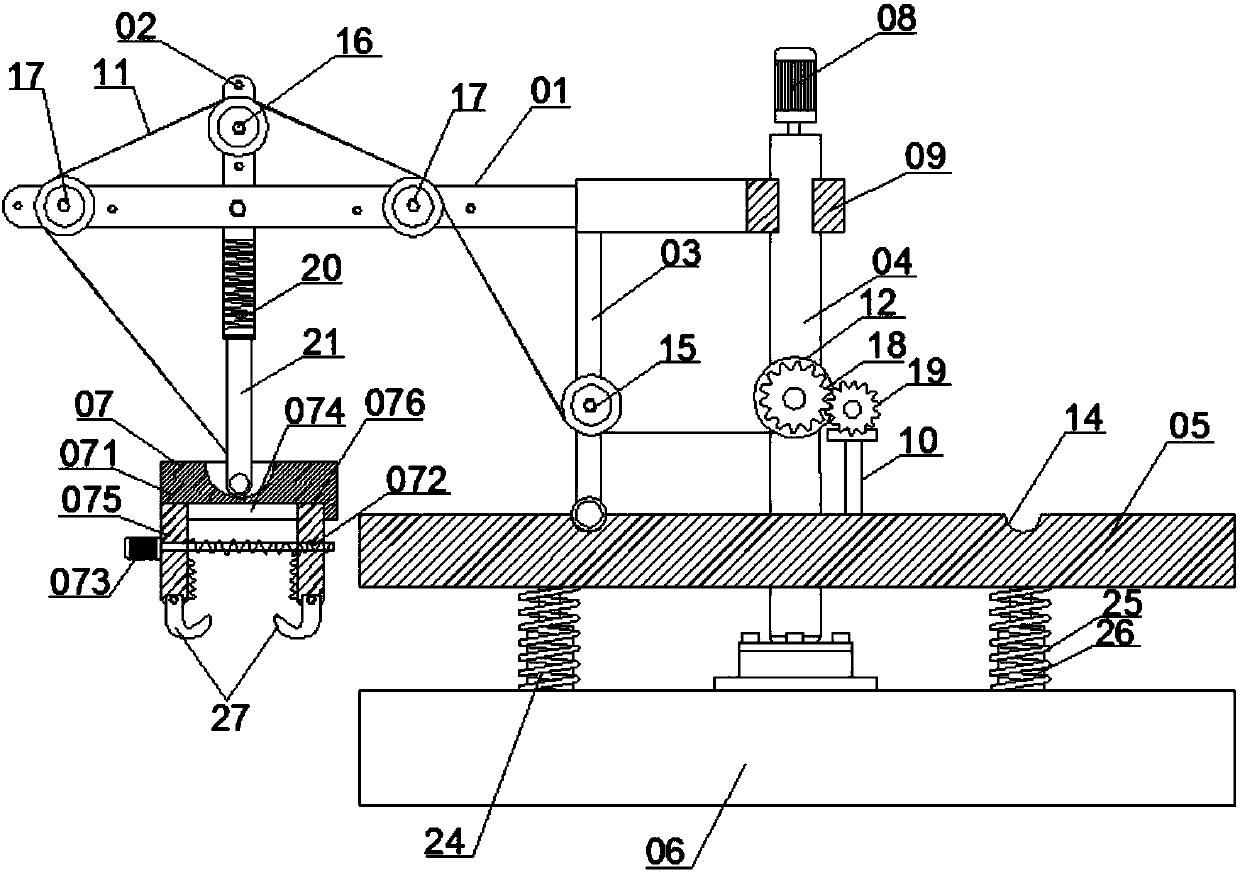

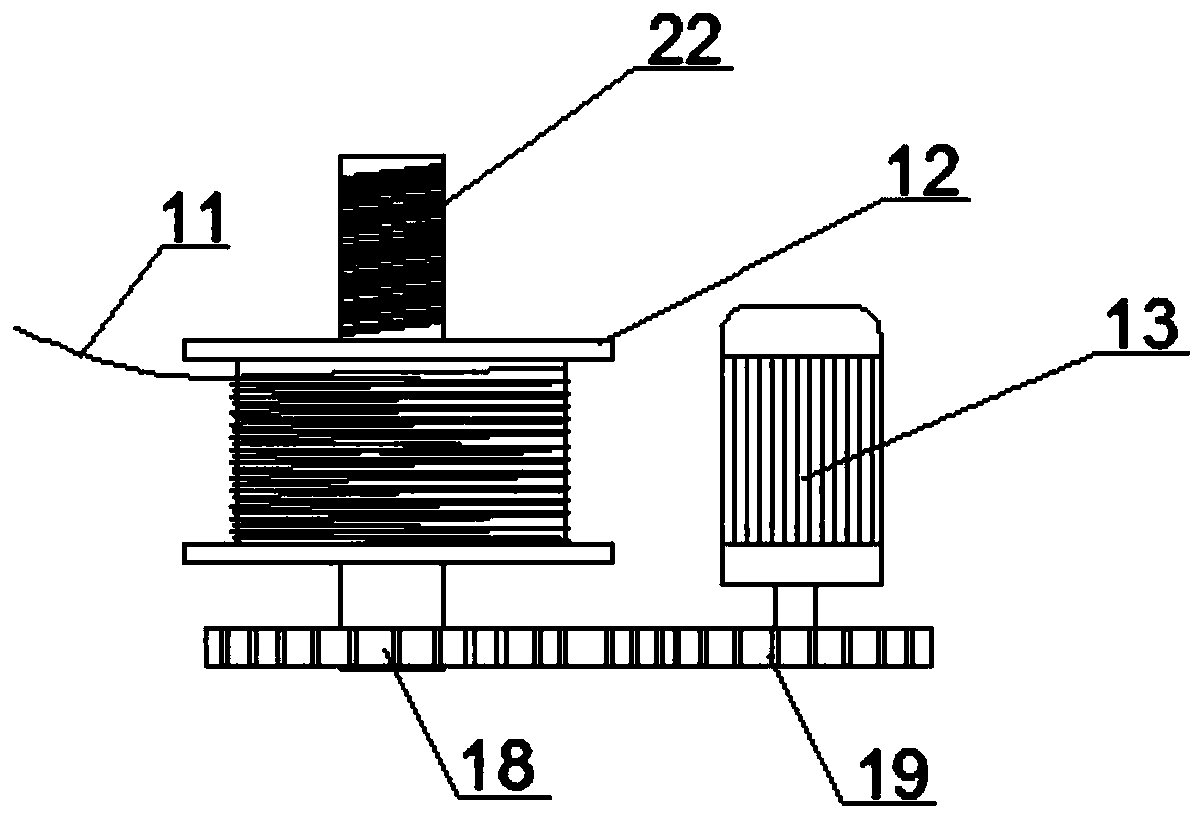

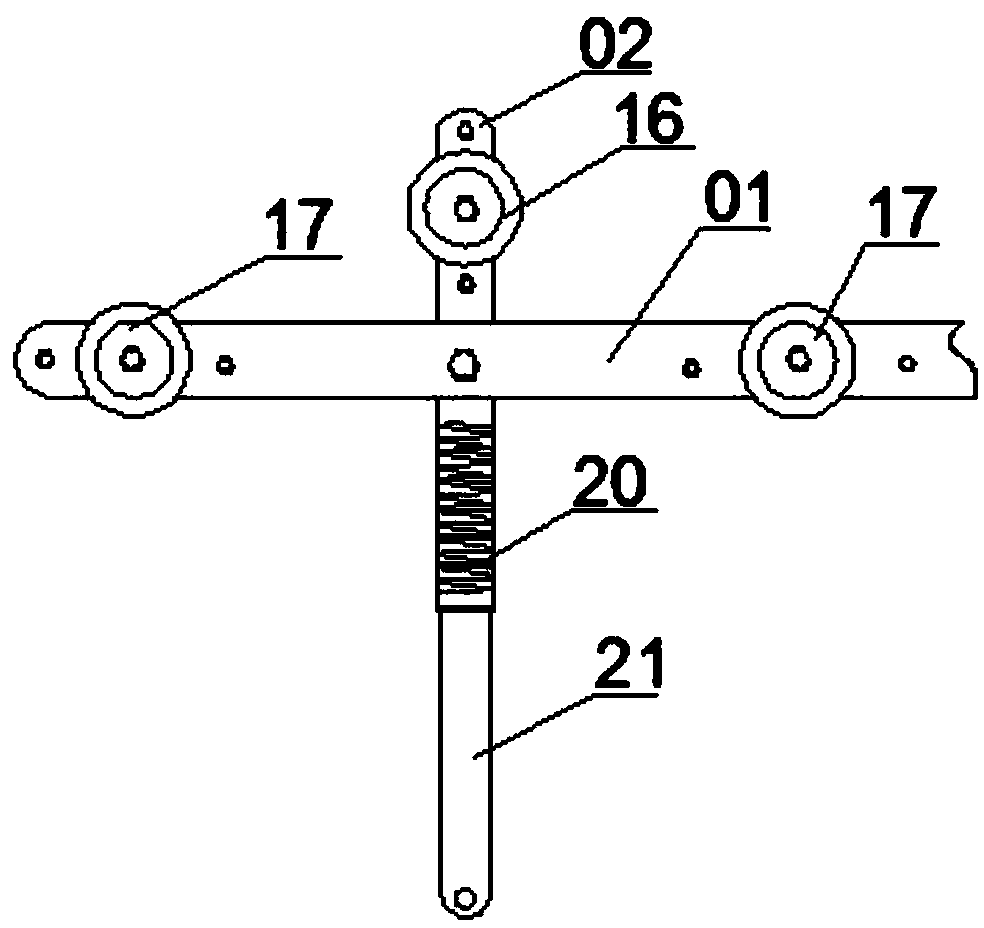

[0028] Please refer to Figure 1 to Figure 4 As shown, this embodiment provides a rotatable lifting device for construction engineering, including a hydraulic rod 01, a connecting rod 02, a support rod 03, a pillar 04, a rotating disc 05, a chassis 06 and a clamping device for clamping construction materials. Device 07, the clamping device 07 includes an connecting plate 071, a locking screw 072 and a micro stepping motor 073, the bottom of the connecting plate 071 is recessed inwardly and a moving guide rail 074 is provided, and the two ends of the moving guide rail 074 are correspondingly provided with a fixed plate 075 And the moving plate 076, the locking screw rod 072 is correspondingly installed between the fixed plate 075 and the moving plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com