Protonation modified g-C3N4 (graphitic carbon nitride) material, preparation thereof and application of protonation modified g-C3N4 material to anode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, nitrogen compounds, chemical instruments and methods, etc., can solve problems such as battery short circuit, damage to electrode structure, and easy peeling of graphite sheets, and achieve good structural stability and high heat. Stable, long-cycle and high-safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

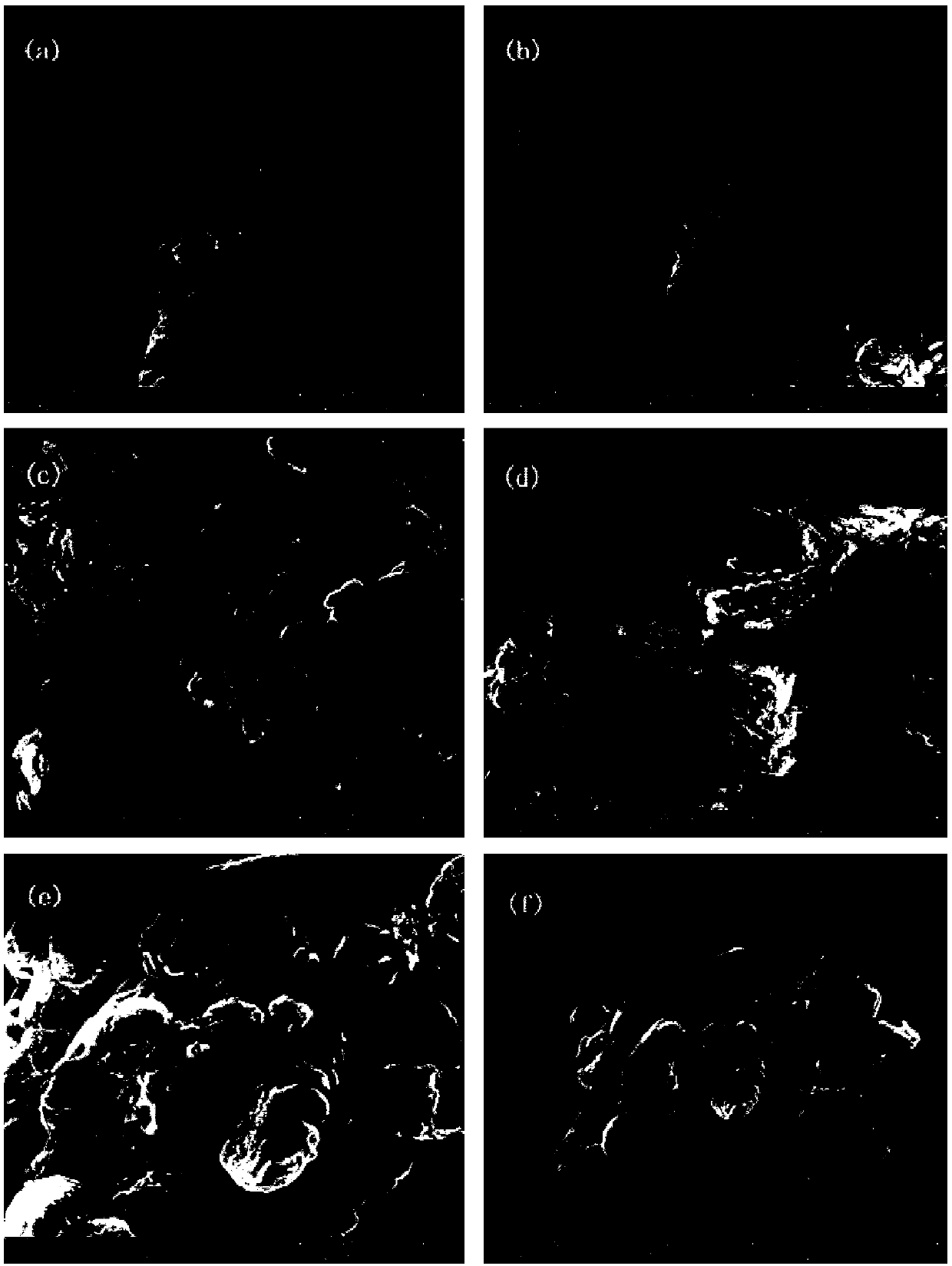

Image

Examples

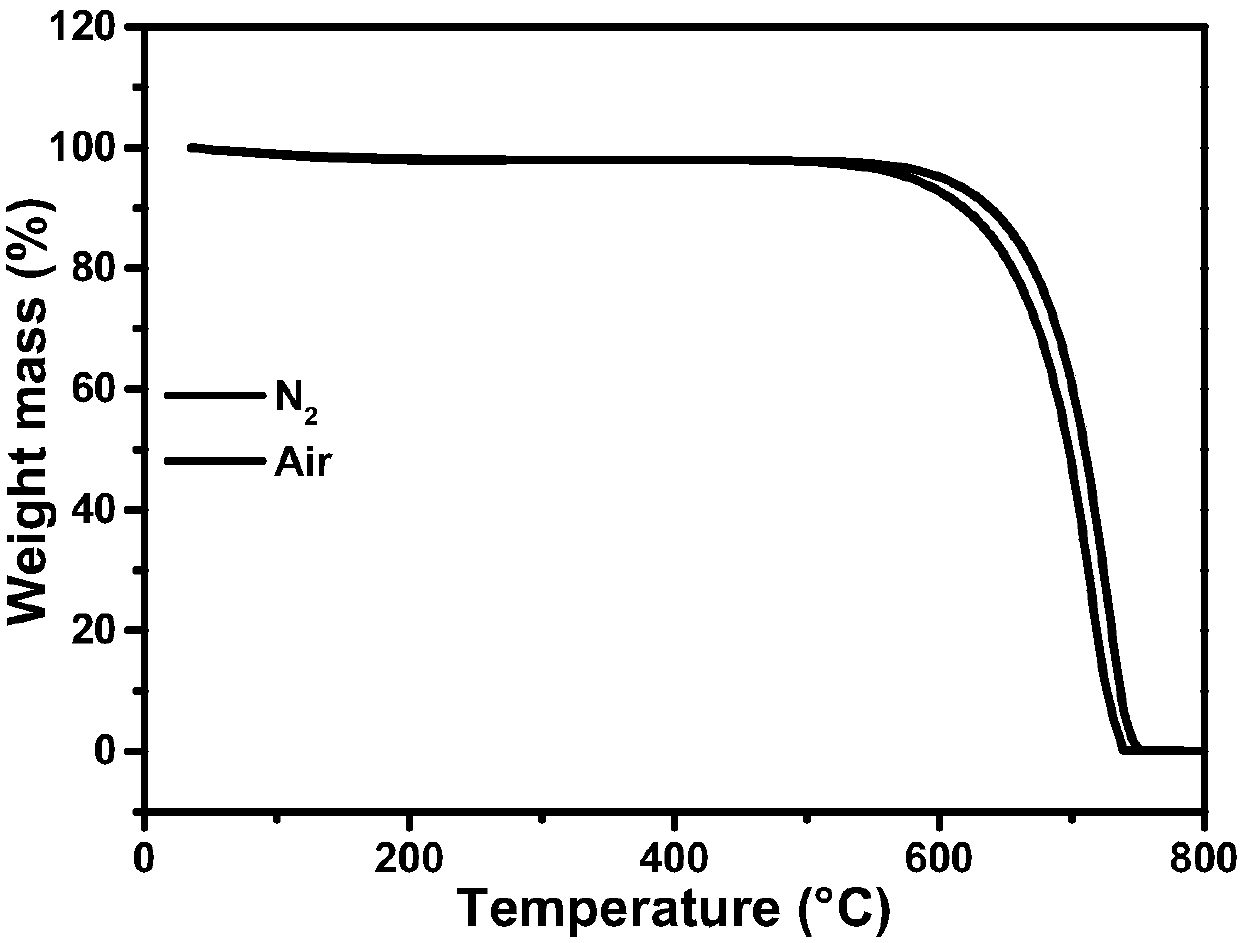

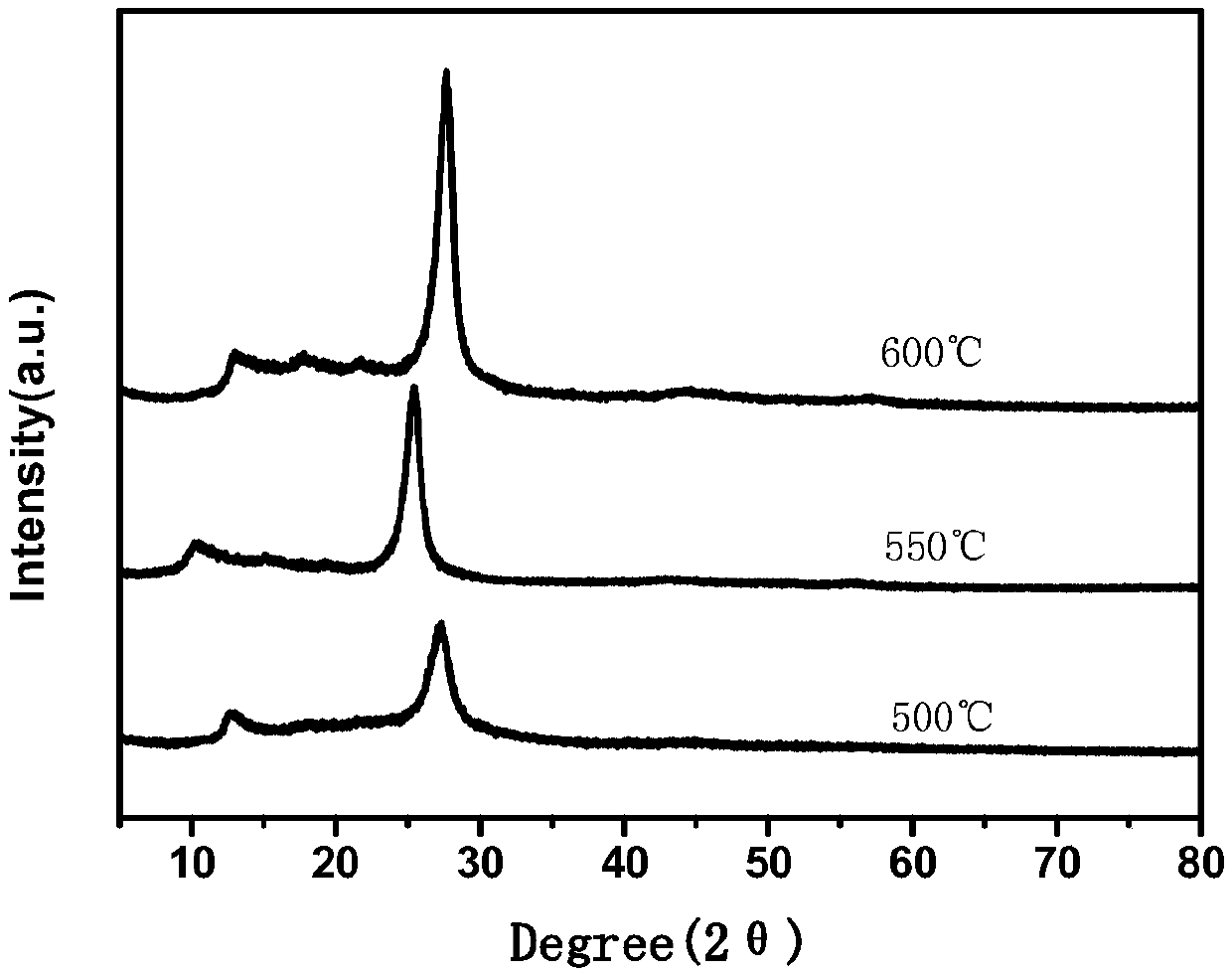

Embodiment 1

[0042] Weigh 5g of dicyandiamide, under a nitrogen atmosphere, at a heating rate of 10°C / min, keep at 500°C for 4h, and grind the product sufficiently.

Embodiment 2

[0044] Weigh 5g of dicyandiamide, under a nitrogen atmosphere, at a heating rate of 10°C / min, keep at 550°C for 4h, and grind the product sufficiently.

Embodiment 3

[0046] Weigh 5 g of dicyandiamide, under a nitrogen atmosphere, at a heating rate of 10° C. / min, keep at 600° C. for 4 hours, and grind the product sufficiently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com