Solid fertilizer-liquid fertilizer integrated production facility and method

A liquid fertilizer and facility technology, applied in the field of solid fertilizer-liquid fertilizer integrated production facilities, can solve the problems of high energy consumption, high construction cost, and secondary pollution of the environment, so as to facilitate operation, solve secondary pollution, and prevent heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

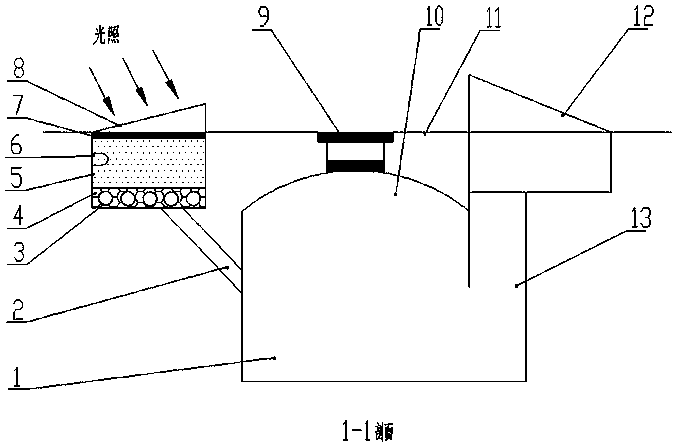

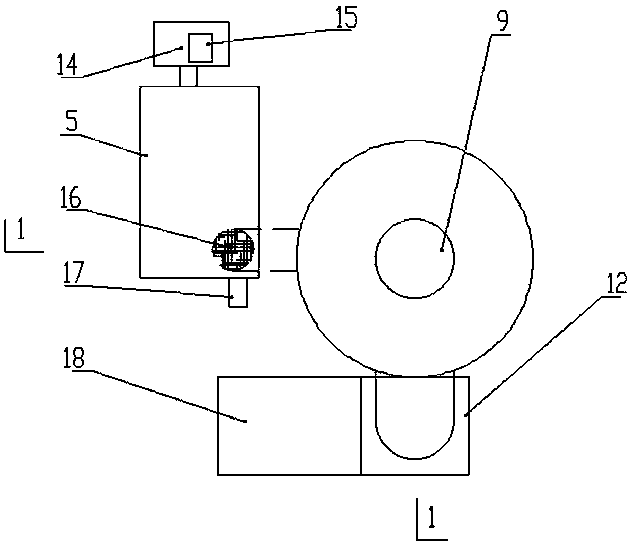

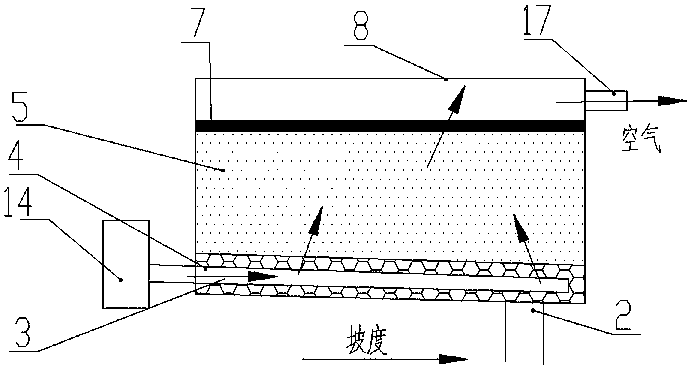

[0036] An integrated solid fertilizer-liquid fertilizer production facility, comprising an aerobic composting bin (5) and an anaerobic fermentation chamber (1), the top of the aerobic composting bin is provided with a light-transmitting plate (8), and a vent is opened on the side ( 17), the bottom is laid with a ventilation pipeline (3), the ventilation pipeline is connected to the blower (14) outside the compost bin, the pipeline is covered with porous filler material (4), and the compost raw materials are laid evenly and loosely on the filler material , the top of the compost layer is covered with heat-absorbing cloth (7), and the anaerobic fermentation chamber is connected with the aerobic compost bin through the feed pipe (2);

[0037] The blower switch is controlled by the control box (15). When the temperature of the compost layer exceeds 60°C or the ventilation interval exceeds 30 minutes, the blower starts to work and lasts for 15 minutes;

[0038]The aerobic compostin...

Embodiment 2

[0048] An integrated production method of solid fertilizer and liquid fertilizer (using crop straw as raw material):

[0049] The first is to start the compost bin: spread fresh wood chips evenly on the ventilation pipeline laid in the bottom of the compost bin, and then chop the straw (chopped to about 1~3cm, and remove stones, plastic waste and other debris at the same time ) mixed evenly with aerobic strains and placed in the compost bin, and finally covered with heat-absorbing cloth on the top of the pile.

[0050] After the start-up is successful, the temperature in the compost bin will gradually increase under the action of microorganisms, and the blower will intermittently blow air into the compost bin under program control to provide oxygen for fermentation; Sunlight forms a greenhouse in the compost bin, which helps to increase the temperature of the composting process. On the one hand, the heat-absorbing cloth plays a role in heat preservation and heat absorption of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com