Ethylene-containing pyrolysis gas non-cryogenic separation method and system thereof

A cryogenic separation and gas cracking technology, applied in the field of petrochemical industry, can solve the problem of low cryogenic separation, achieve the effects of reducing energy consumption and equipment requirements, high material recovery rate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Provide a kind of ethylene-containing cracked gas non-cryogenic separation system in embodiment, this separation system comprises:

[0048] The purification gas pipeline (S100) of the reactor discharge gas, the first cooler (E101) is arranged on the purification gas pipeline of the reactor discharge gas, and the first cooler (E101) is used to purify the reactor discharge gas Air cooling to -40°C to 10°C;

[0049] The absorbent pipeline (S107), the absorbent pipeline (S107) is provided with a second cooler (E102) for cooling the absorbent;

[0050] Absorption tower (T101), the inlet of the gas phase material arranged in the middle and lower part of the side wall of the absorption tower is connected with the purified gas pipeline (S100) of the reactor discharge gas, and the inlet of the liquid phase material arranged in the middle and upper part of the side wall of the absorption tower is connected with the absorbent pipeline (S107) is connected, the gas phase material o...

Embodiment 2

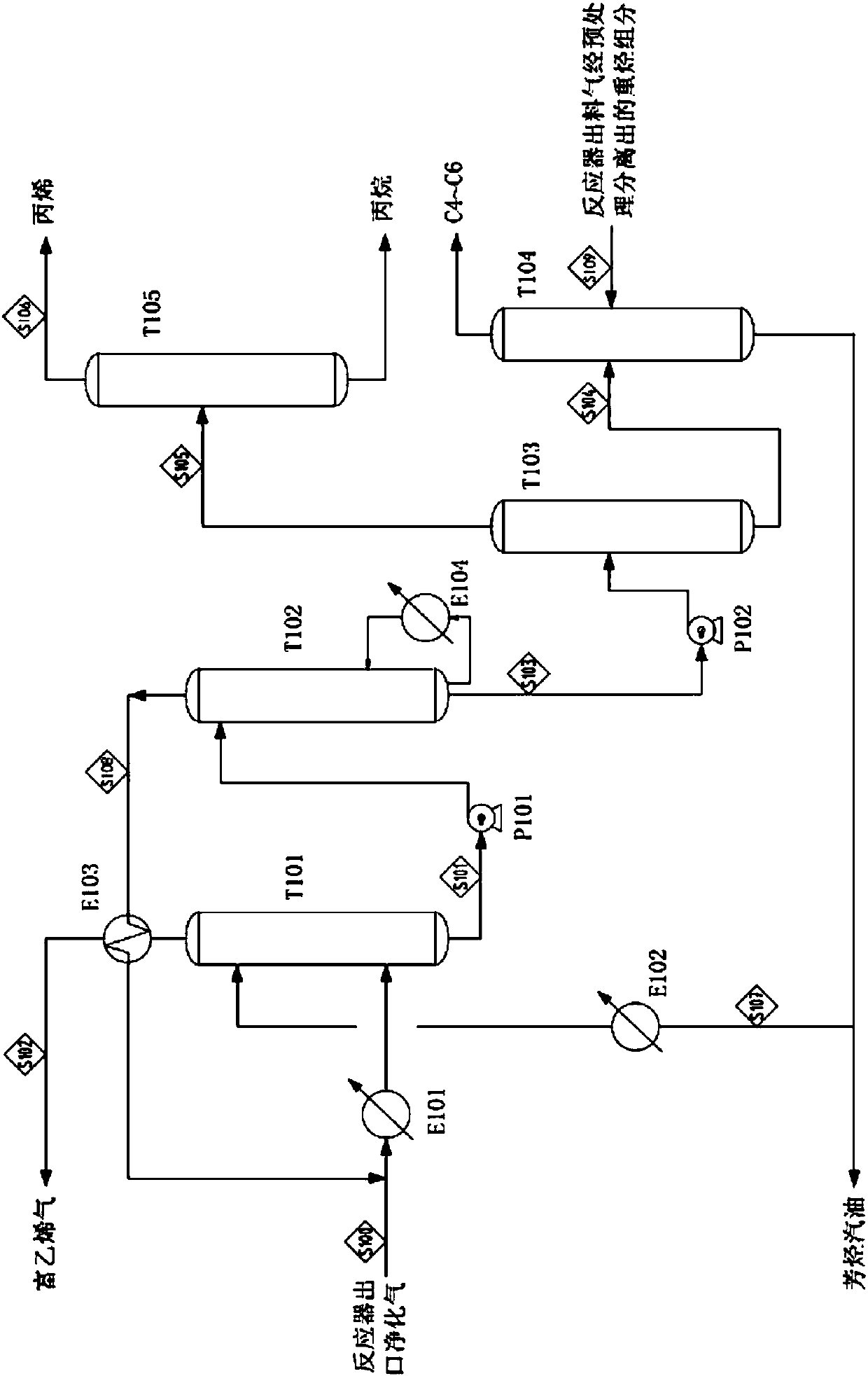

[0059] This embodiment provides a non-cryogenic separation method for ethylene-containing cracked gas, which uses the device in Example 1, and its flow chart is shown in figure 1 , the specific process is as follows:

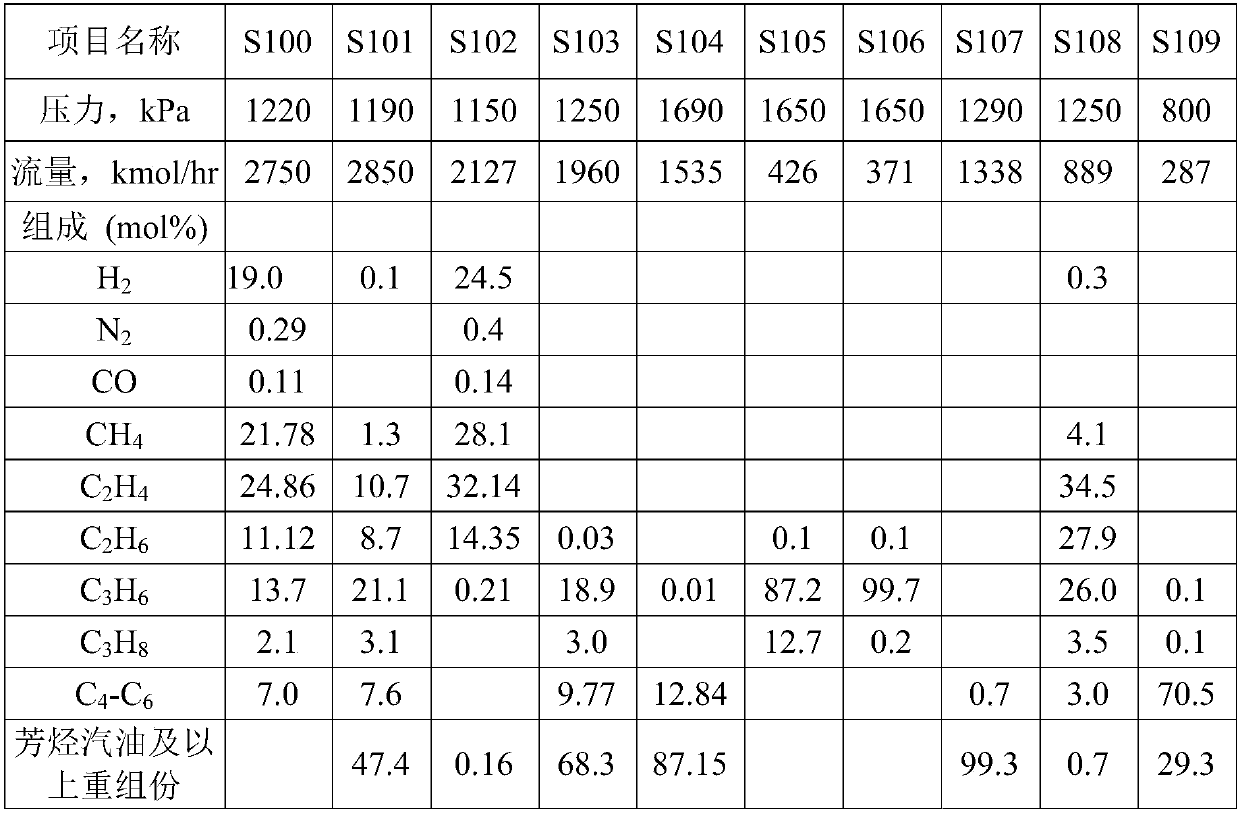

[0060] (1) Pretreatment is carried out to the reactor output gas (the output gas of the cracking furnace of a certain cracking olefin process), and the pretreatment includes chilling, compression, removal of acid gases, alkynes, dienes and drying; and then The purified reactor output gas is introduced into the separation system through the pipeline S100, and the cooler E101 on the pipeline S100 cools the gas to -25°C and then introduces it into the absorption tower T101;

[0061] (2) The top gas of the absorption tower T101 (light components of C2 and below) and the top gas of the desorption tower T102 are exchanged by the cooler E103 and then sent out of the boundary area to obtain the product ethylene-rich gas. The ethylene yield in S102 is 99.9% % or more; t...

Embodiment 3

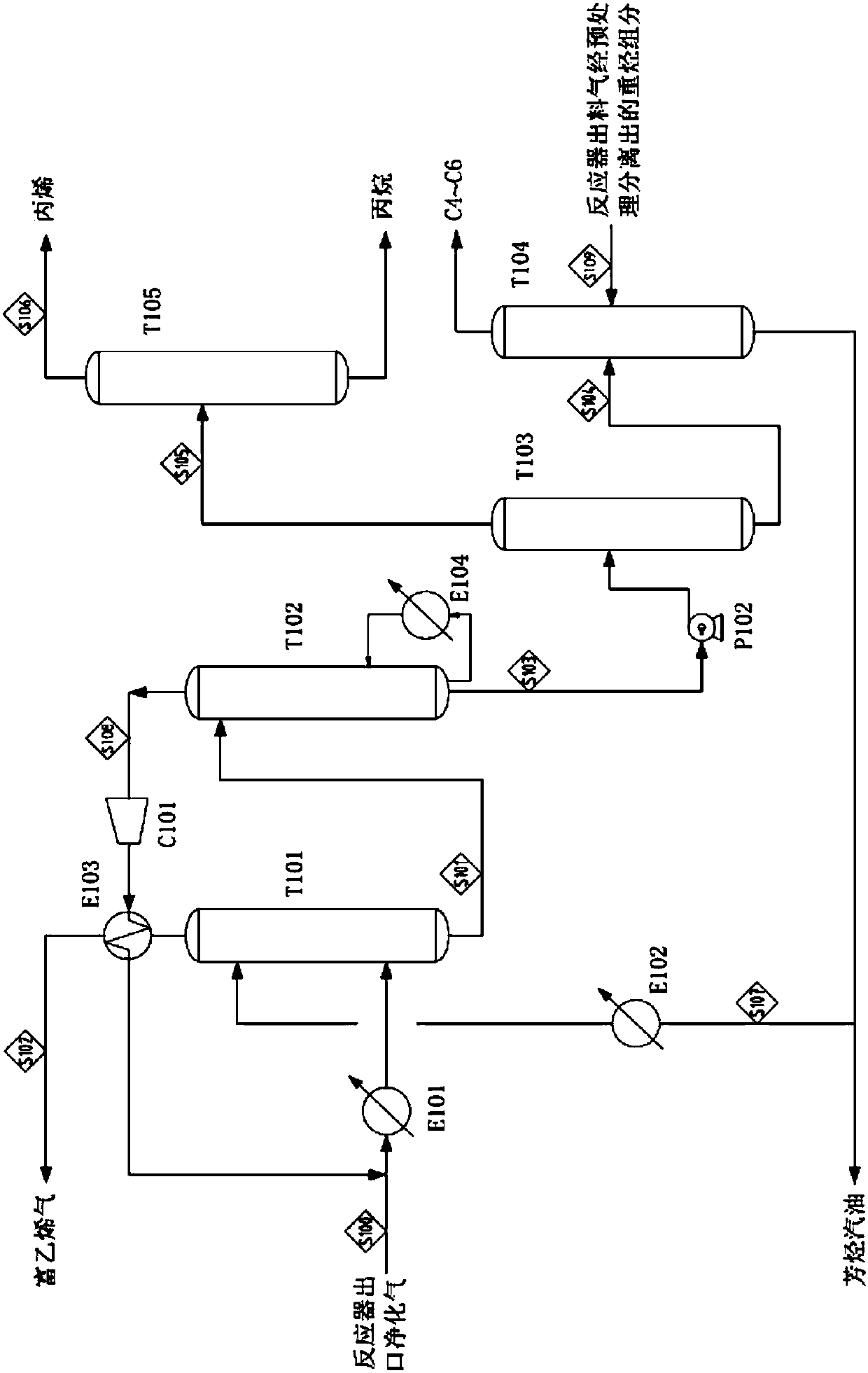

[0070] This embodiment provides a non-cryogenic separation method for ethylene-containing cracked gas, which uses the device in Example 1, and its flow chart is shown in figure 2 , the specific process is as follows:

[0071] (1) Pretreatment is carried out to the reactor output gas (the output gas of the cracking furnace of a certain cracking olefin process), and the pretreatment includes chilling, compression, removal of acid gases, alkynes, dienes and drying; and then The purified reactor output gas is introduced into the separation system through the pipeline S100, and the cooler E101 on the pipeline S100 cools the gas to -25°C and then introduces it into the absorption tower T101;

[0072] (2) The top gas of the absorption tower T101 (light components of C2 and below) and the top gas of the desorption tower T102 are exchanged by the cooler E103 and then sent out of the boundary area to obtain the product ethylene-rich gas. The ethylene yield in S102 is 99.9% % or more; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com