Seal point labeling method and system for detection of VOCs pollution source

A pollution source and point group technology, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as affecting work efficiency, inconvenient tracking and use, and achieve the effect of reducing workload, intuitive operation, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

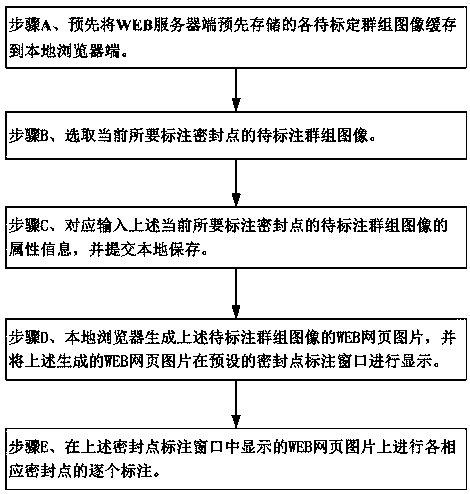

[0056] figure 1 It is a specific implementation of the sealing point labeling method for VOCs pollution source detection in the present invention. In this specific embodiment, the sealing point labeling method for VOCs pollution source detection includes the following steps A-E.

[0057] Step A, pre-caching the group images to be calibrated stored on the WEB server to the local browser.

[0058] Step B. Select the group images to be marked that currently need to be marked with sealing points.

[0059] Specifically, from the group images to be marked that are cached in the local browser as described in the above step A, select the group images to be marked that currently need to be marked with sealing points through the local browser.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com