Square cylindrical gate embedded U-shaped channel field effect transistor and manufacturing method thereof

A transistor and U-shaped technology, applied in the field of ultra-large-scale integrated circuit manufacturing, can solve the problems of difficulty in further improving the integration level and complex structure, and achieve the effect of simple structure, improved integration level, and high integration level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further explained below in conjunction with the drawings:

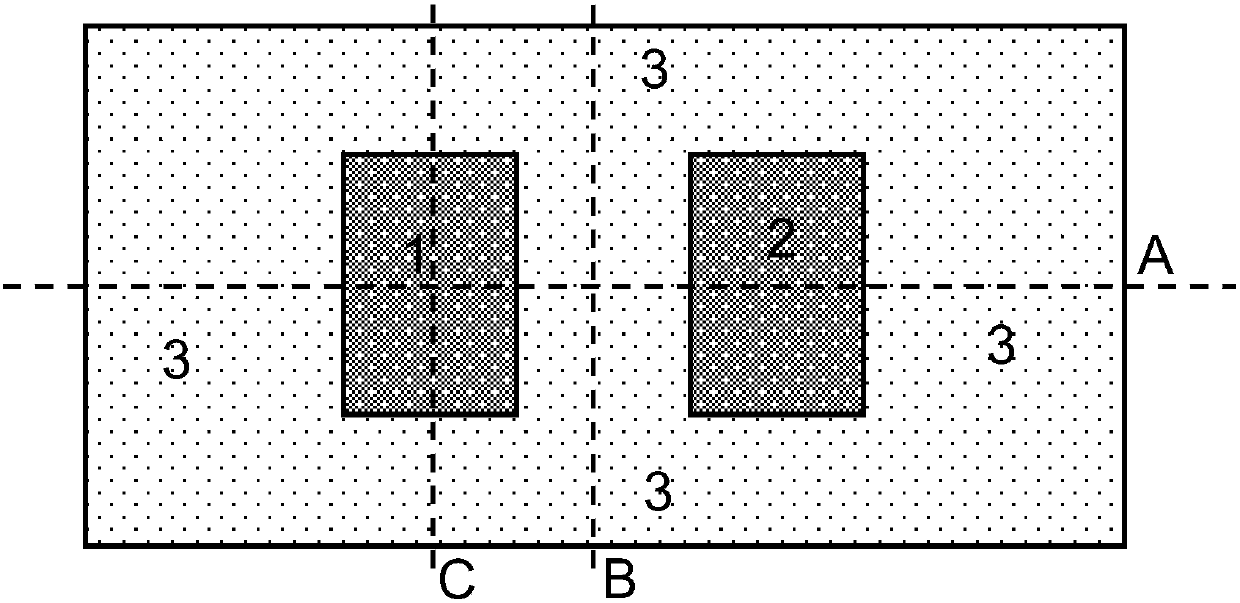

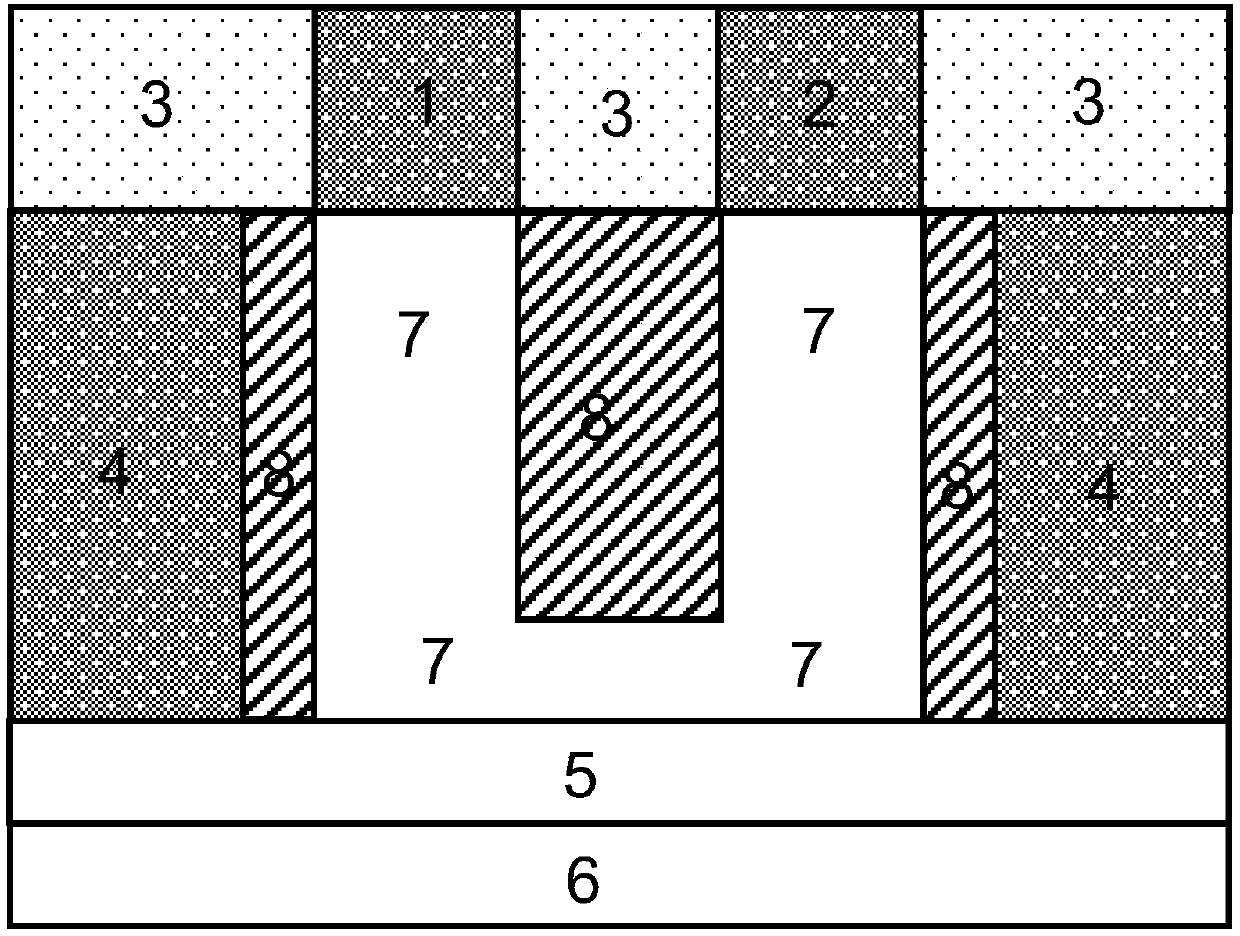

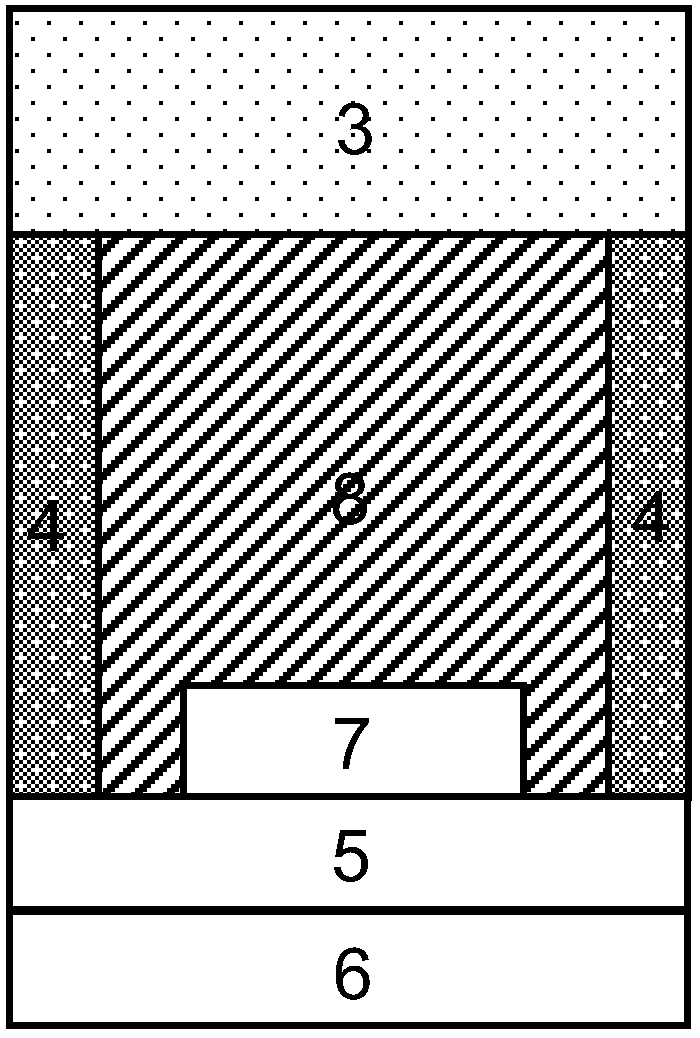

[0050] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a square cylindrical gate embedded U-shaped channel field effect transistor includes a silicon substrate 6 of an SOI wafer, characterized in that: an insulating layer 5 of the SOI wafer is above the silicon substrate 6 of the SOI wafer Above the insulating layer 5 of the SOI wafer there is a U-shaped single crystal silicon 7, a gate insulating layer 8 and a square cylindrical gate electrode 4; the U-shaped single crystal silicon 7 has a U-shaped groove structure feature, the inside and front and back of the groove The left and right side surfaces are filled and covered by the gate insulating layer 8, and the left and right sides of the U-shaped groove formed by the U-shaped monocrystalline silicon 7 do not contain any other structural layers except for the gate insulating layer 8. The gate insulating layer 8 The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com