Preparing method of cube-sugar-shaped nickel carbonyl powder

A technology of nickel carbonyl powder and nickel carbonyl, which is applied in the field of preparation of sugar-like nickel carbonyl powder, can solve the problems of easy ignition, substandard indicators, insufficient control and monitoring means, etc., so as to reduce production costs and improve the direct yield of products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] A kind of preparation method of sugar cube-shaped nickel carbonyl powder of the present invention, the untreated exhaust gas containing free nickel carbonyl produced in the production process of carbonyl nickel powder is passed into the decomposer of the decomposition system, and the amount containing free nickel carbonyl accounts for The rectification treatment liquid volume is 6-7%. The decomposer of the decomposition system is heated in sections, which are divided into seven sections. The heating temperature of the first five sections is lower than 280°C in each section, and the temperature of the sixth and seventh sections is lower than 220°C. The amount of exhaust gas to be treated is based on the actual amount of exhaust gas from rectification.

[0012] Further, the temperature distribution of the seven stages of the decomposer of the decomposition system is 255°C-275°C for the first stage, 260°C-280°C for the second stage, 245°C-275°C for the third stage, 230°C-27...

Embodiment 1

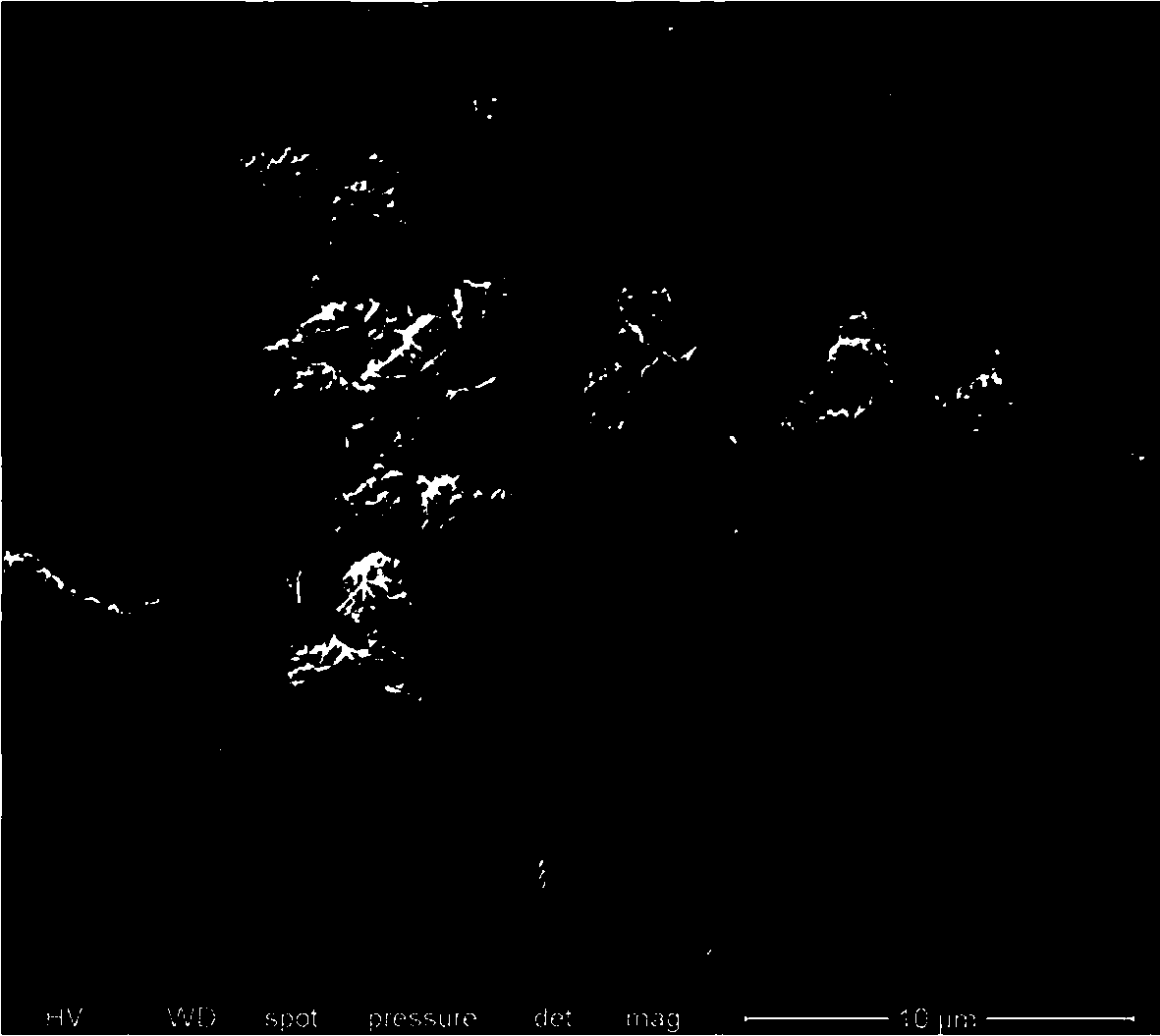

[0015] In the process of producing nickel carbonyl powder using the exhaust gas of the rectification tower, the temperature distribution of the seven stages of the decomposer is 275°C for the first stage, 280°C for the second stage, 275°C for the third stage, 270°C for the fourth stage, 255°C for the fifth stage, and 220°C for the sixth stage. ℃, 195℃ in the seventh stage, the residence time of carbonyl nickel powder in the decomposer is 2min. The bulk density of nickel carbonyl powder produced is 2.51g / cm 3 , with an average particle size of 6.6 μm and a carbon content of 0.14%, the morphology tends to be regular, and the chain bead-shaped nickel carbonyl powder with sugar cube-like structure (such as figure 1 ).

Embodiment 2

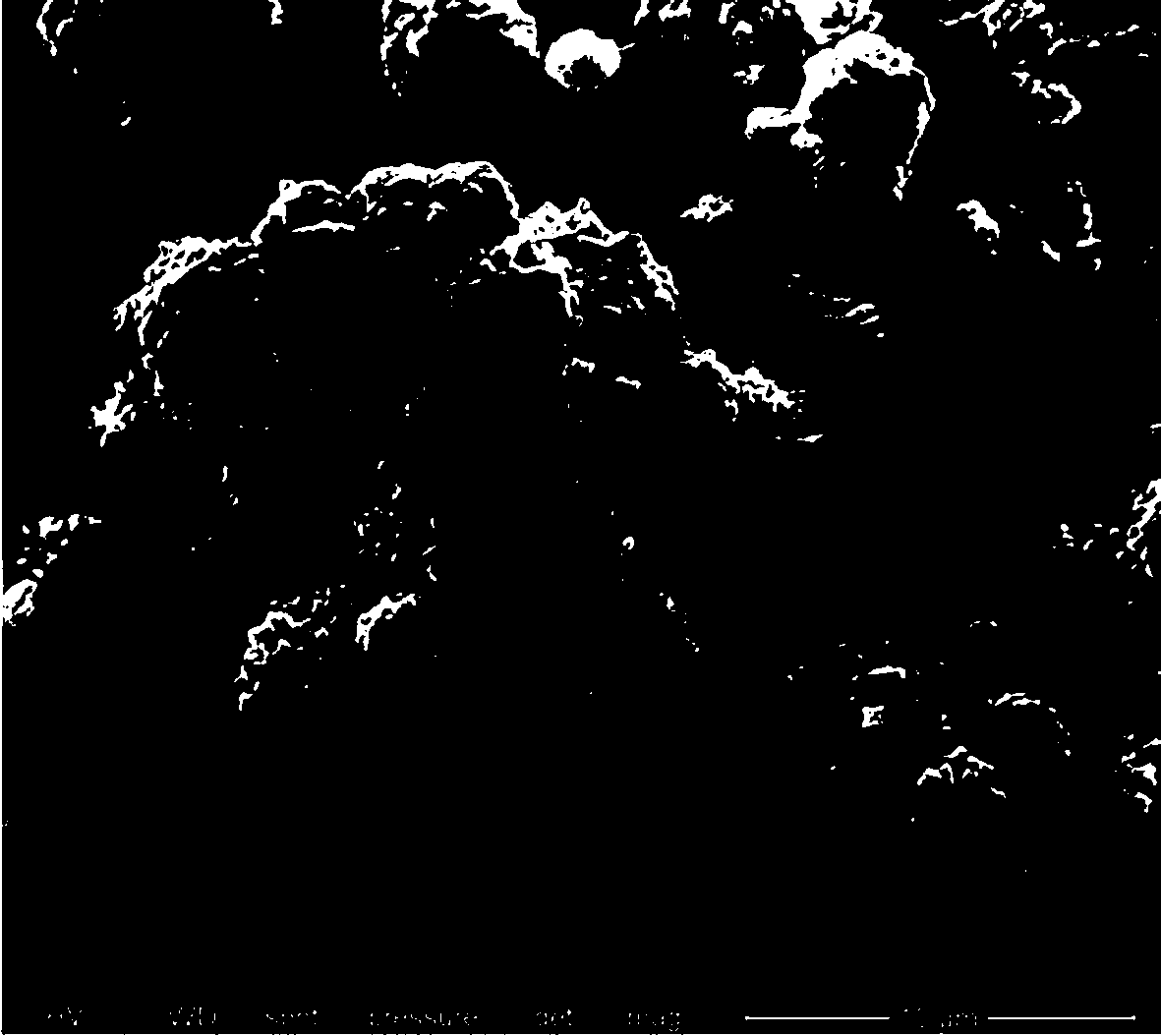

[0017] In the process of producing nickel carbonyl powder using the exhaust gas of the rectification tower, the temperature distribution of the seven stages of the decomposer is 265°C for the first stage, 270°C for the second stage, 255°C for the third stage, 260°C for the fourth stage, 250°C for the fifth stage, and 210°C for the sixth stage. ℃, the seventh stage is 195℃, the residence time of carbonyl nickel powder in the decomposer is 3min. The bulk density of nickel carbonyl powder produced is 2.67g / cm 3 , the average particle size is 6.9 μm, the morphology of the carbon content of 0.12% tends to be regular, and the particles are gradually dispersed nickel carbonyl powder (such as figure 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com