Silt ex-situ solidification treatment device and method

A technology for solidification treatment and sludge, applied in the direction of fixed/solidified sludge treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of easy local accumulation, affect the later strength, limit the scope of application, etc., and achieve sludge reduction. The effect of resource utilization, improving the strength of solidified soil and reducing the moisture content of silt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

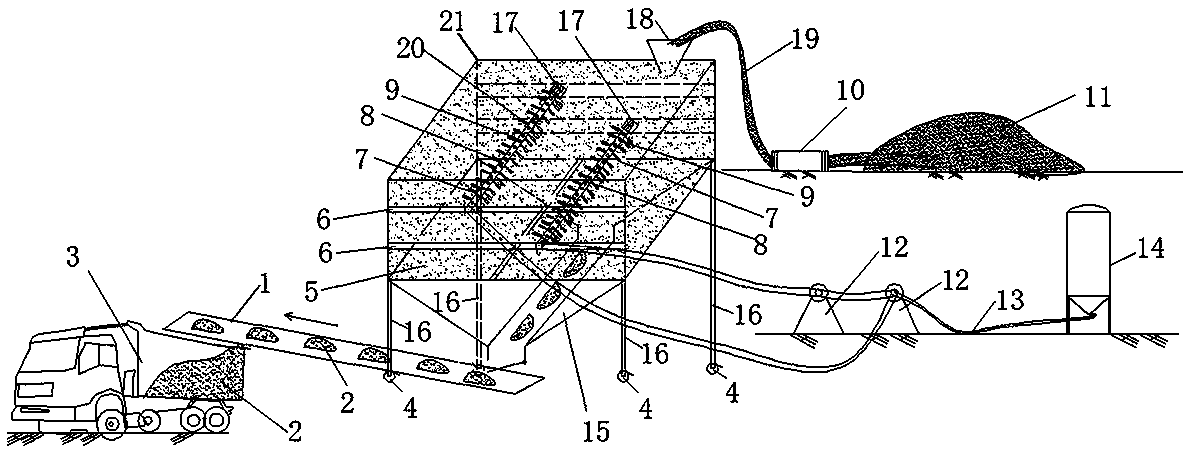

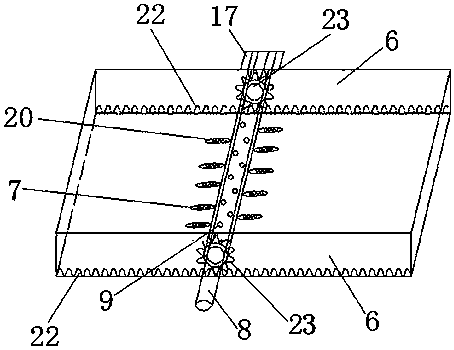

[0027] Such as figure 1 and 2Shown: this embodiment is a kind of sludge heterogeneous solidification processing equipment, including solidification box, piston type mud pump 10, mud pipe 19, slurry pump 12, slurry pipe 13 and curing agent slurry storage tank 14; Type mud delivery pump 10 transports the sludge 11 to be treated into the solidification box through the mud delivery pipe 19, and the solidification box includes a box body 21, a stirring device, a mud inlet 18, a bottom cover 5 and an inclined funnel 15, and the mud inlet 18 Set on the top of the box body 21, the inclined drain 15 is arranged at the bottom of the box body 21, the bottom cover 5 is movably inserted on the box body 21 and used to open or close the entrance of the inclined drain 15, the stirring device includes a stirring rod The rolling groove 6, the stirring rod 8 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com