Anti-PID photovoltaic EVA encapsulation adhesive film and preparation method thereof

A film and antioxidant technology, applied in the direction of adhesive, film/sheet without carrier, film/sheet adhesive, etc., can solve the failure of anti-PID effect, decrease of material polarity, increase the volume of EVA film Resistivity and other issues, to achieve good reliability and stability, ensure reliability and stability, and good anti-PID performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

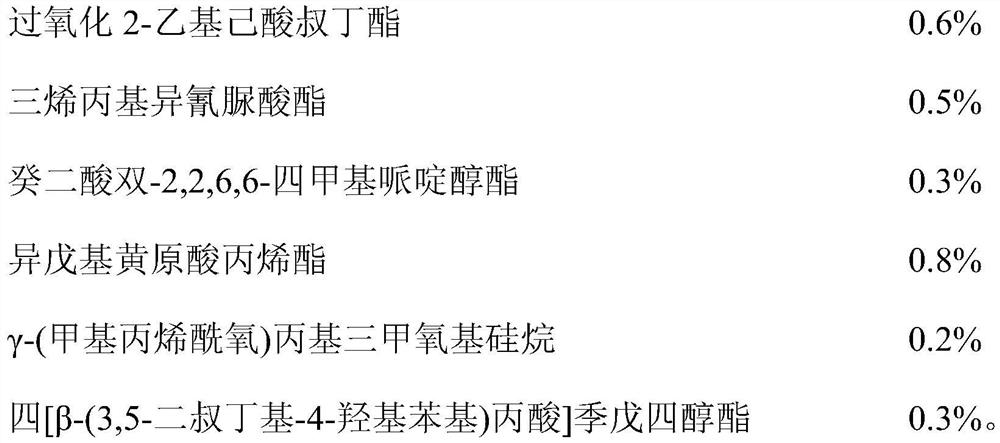

[0038] In the present embodiment, the preparation raw material of EVA adhesive film comprises EVA resin and by the mass of EVA resin, the component of percentage content is as follows:

[0039]

[0040] EVA resin, tert-butyl peroxide 2-ethylhexanoate, triallyl isocyanurate, bis-2,2,6,6-tetramethylpiperidinol sebacate, isopentyl Propyl xanthate, γ-(methacryloyloxy)propyltrimethoxysilane and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester mixed, extruded Go out, calender into adhesive film, obtain described EVA adhesive film.

Embodiment 2

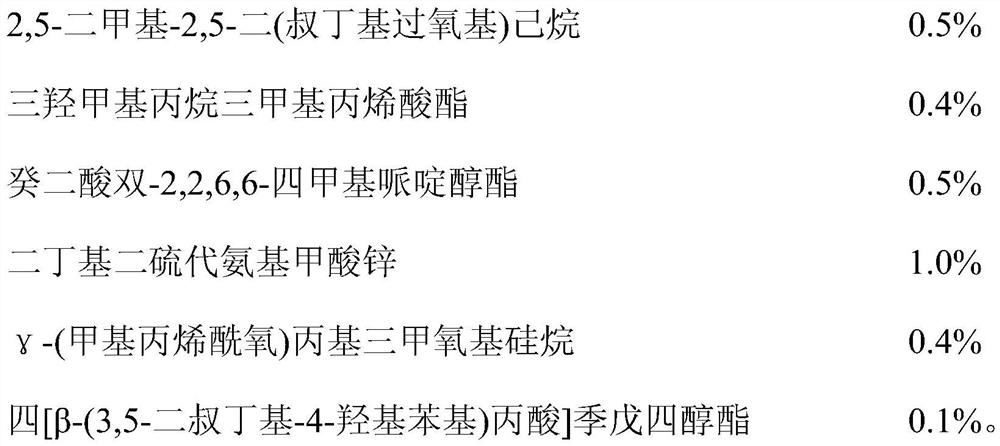

[0042] In the present embodiment, EVA film comprises EVA resin and by the mass of EVA resin, the component of percentage content is as follows:

[0043]

[0044] EVA resin, 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, trimethylolpropane trimethacrylate, bis-2,2,6 sebacate, 6-tetramethylpiperidinol ester, zinc dibutyldithiocarbamate, γ-(methacryloyloxy)propyltrimethoxysilane and tetrakis[β-(3,5-di-tert-butyl- 4-Hydroxyphenyl)propionic acid]pentaerythritol esters were mixed, extruded by an extruder at a barrel temperature of 80°C, and calendered to form an adhesive film to obtain the EVA adhesive film.

Embodiment 3

[0046] In the present embodiment, EVA film comprises EVA resin and by the mass of EVA resin, the component of percentage content is as follows:

[0047]

[0048]

[0049] EVA resin, tert-butyl peroxide 2-ethylhexanoate, trimethylolpropane trimethacrylate, bis-2,2,6,6-tetramethylpiperidinol sebacate, isoamyl propylene xanthate, γ-(methacryloyloxy)propyltrimethoxysilane and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, Using an extruder to extrude at a barrel temperature of 70° C., and calendering to form an adhesive film to obtain the EVA adhesive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com