New inert grout and combined grouting technology for shield tunneling in upper soft and lower hard water-rich strata

A combined grouting technology for water-rich strata, applied in underground chambers, shaft equipment, wellbore linings, etc., can solve problems such as untargeted grouting methods, excessive water seepage in front of the face, and affecting the stability of the face , to achieve the effects of small consolidation volume shrinkage, increased slurry cost, and repeated filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

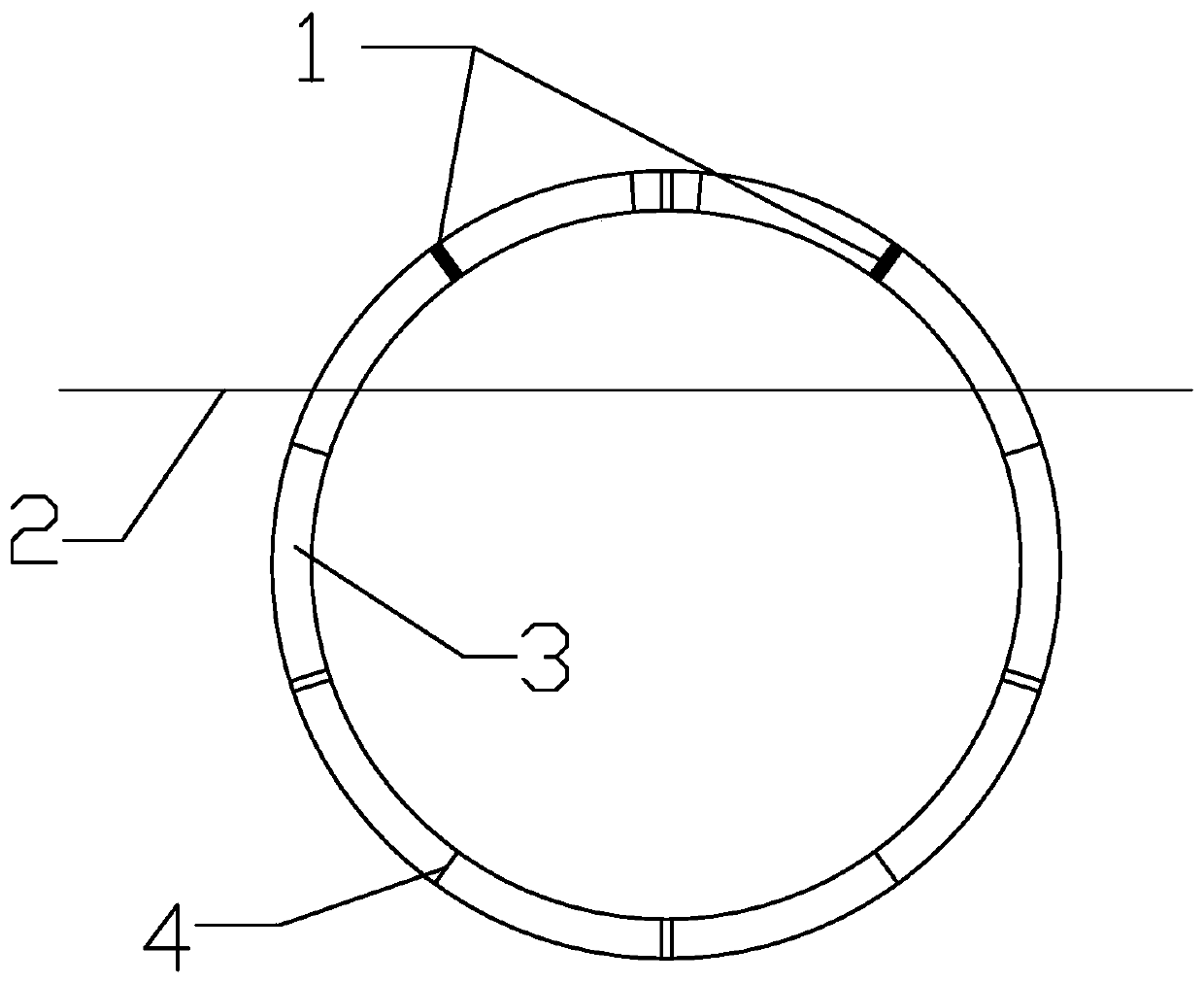

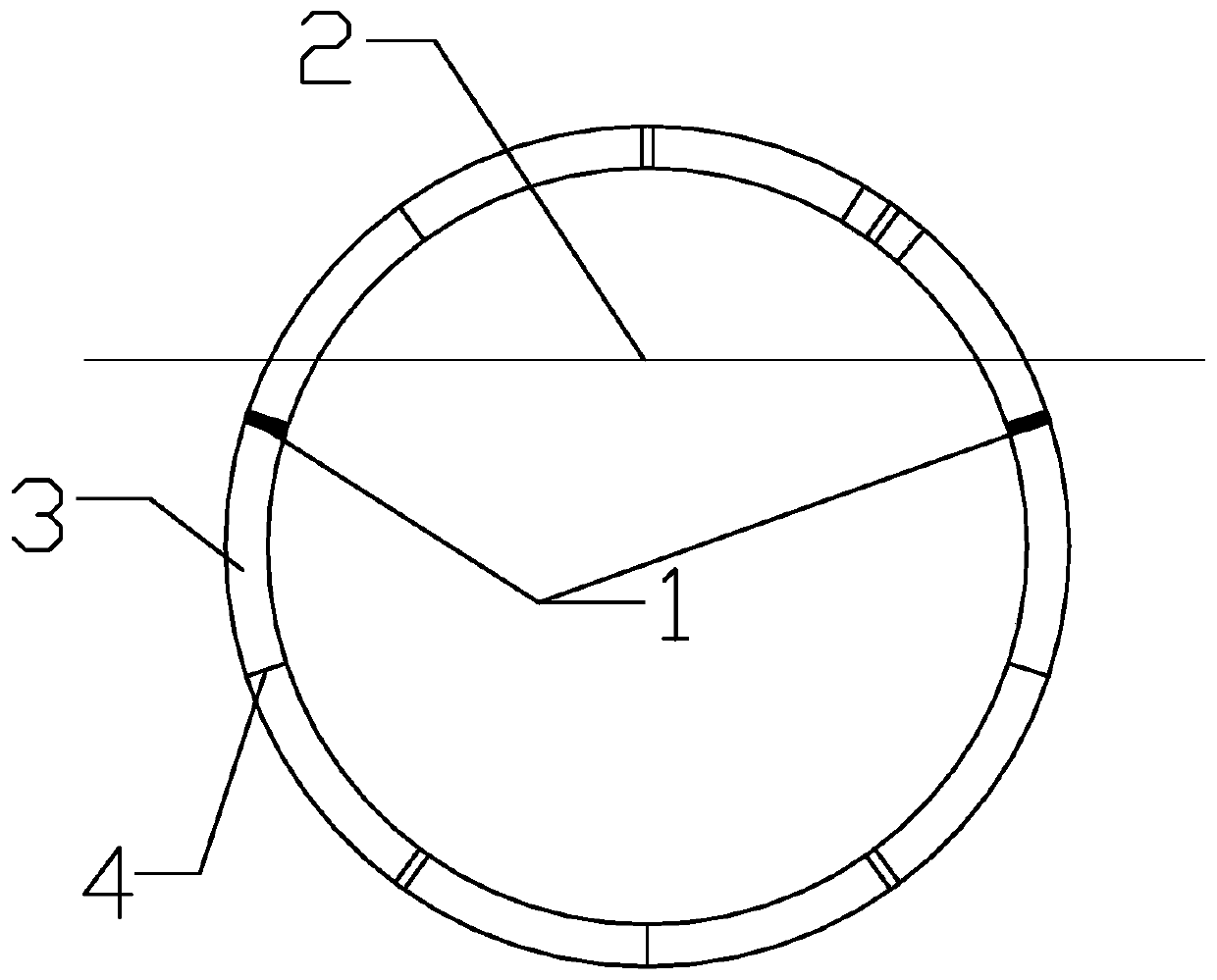

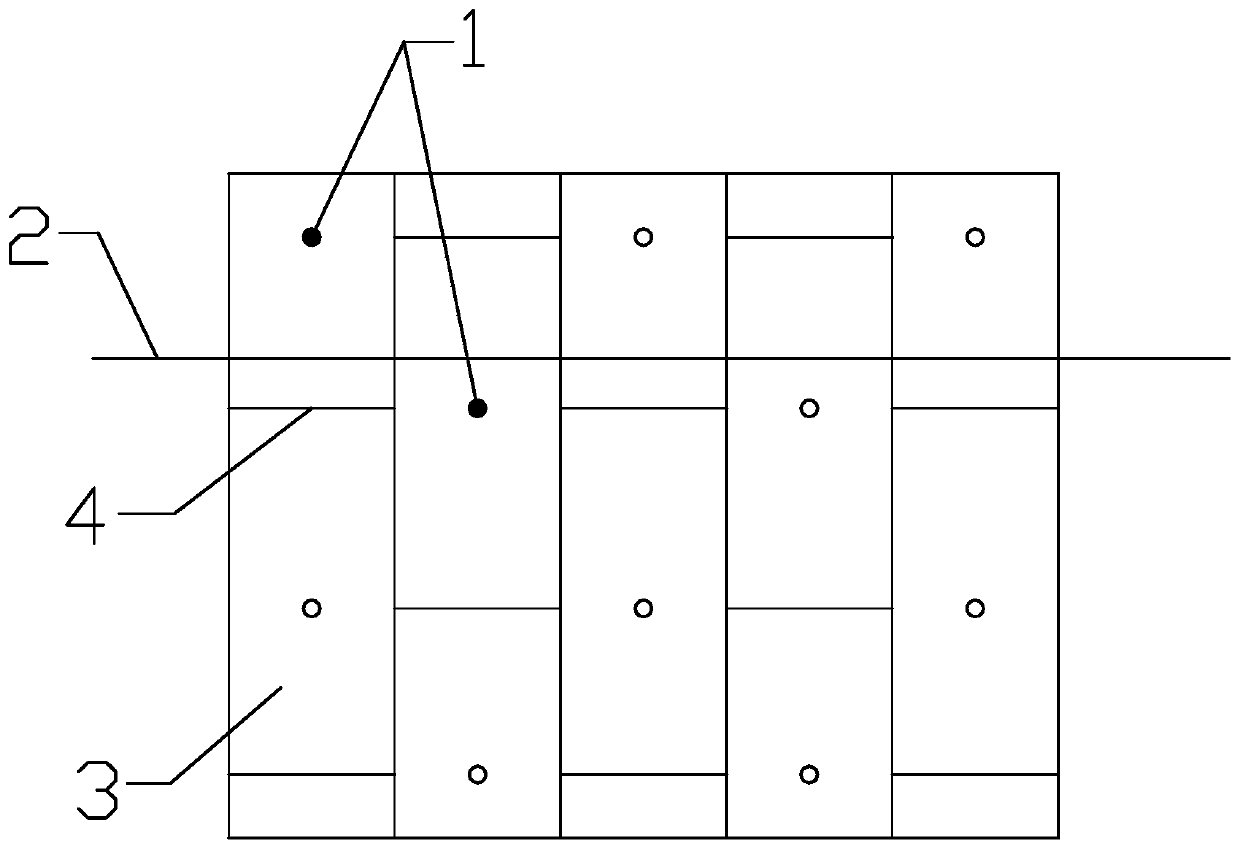

Method used

Image

Examples

Embodiment 1

[0034] Example 1: This example is aimed at Section 3 of Hefei Metro Line 2. The shield section includes a soft top and bottom hard, full-faulted flour-soil silt stratum, and it is close to the Feihe River. The groundwater content is rich and the shield construction is difficult. Larger. During the construction of other bid sections with similar geology, ground subsidence and collapse occurred continuously, and many emergency incidents occurred. The inventors used the method of the present invention to perform combined grouting. There was no settlement exceeding the limit in this bid section. The specific process steps are as follows :

[0035] (1) Prepare a new type of inert grout for simultaneous grouting: prepare the materials for the simultaneous grouting grout according to the following formula:

[0036]

[0037]

[0038] Among them, fly ash soil uses bulk fly ash, the above materials are mixed with general mixing equipment, fly ash uses bulk fly ash, pay attention to strictly...

Embodiment 2

[0044] Example 2: The stratum lithology in the interval between Shijing Station and Tinggang Station in Biao 8 in Guangzhou has changed greatly. The top of the tunnel structure is mainly composed of alluvial and alluvial sand layers, and the alluvial soil layer is in the residual soil layer. The bottom of the tunnel is mainly Located in the strong weathered rock layer and rock slightly weathered layer, it is shown as the upper soft and lower hard stratum, which is prone to surface deformation, and the environment along the shield tunnel is complicated. It is necessary to pass through the houses along the street of Hongxing East 1st Lane, Hongxing Bridge, postal building, Sanfu Office buildings, rivers, etc., in order to ensure the safety of shield construction and avoid the risks caused by settlement, in January 2017, the combined grouting process in the present invention was adopted to ensure that the entire construction was safe and controllable, and the settlement was within t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com