Phase-change energy storage device lattice interlayer structure based on additive manufacturing

A technology of additive manufacturing and sandwich structure, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement. Good application prospects, high manufacturing precision, and the effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

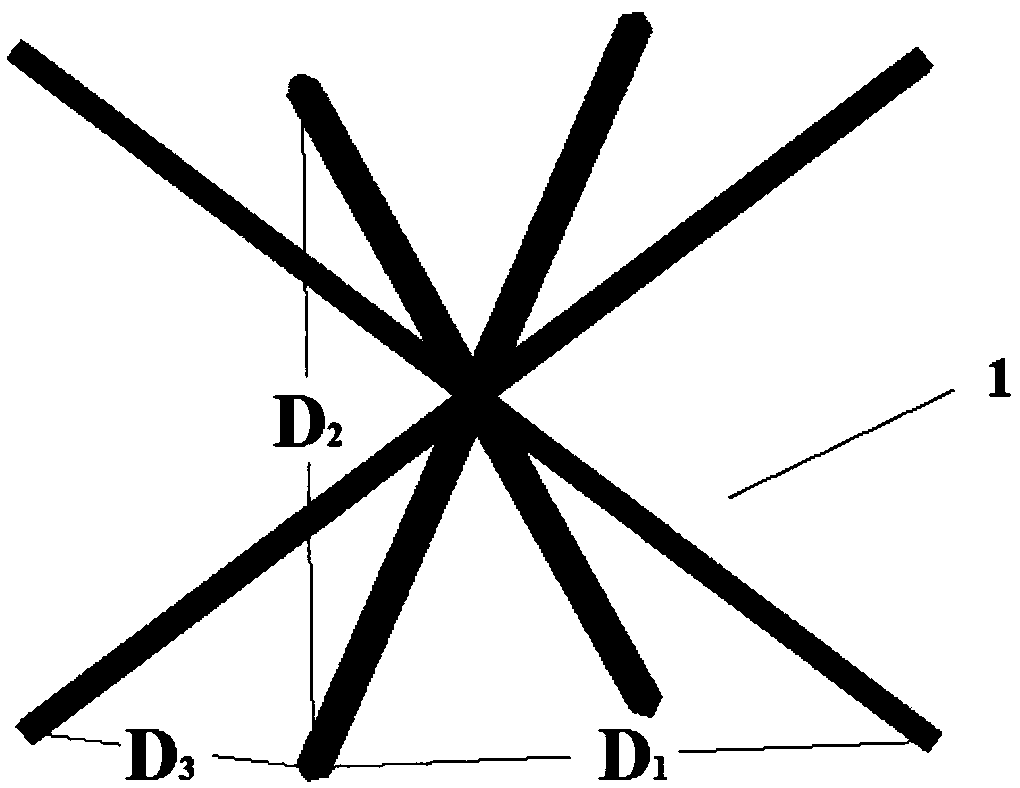

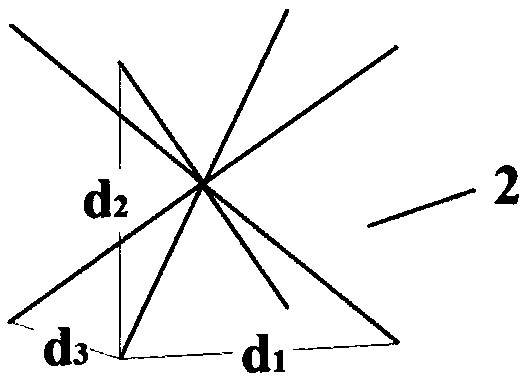

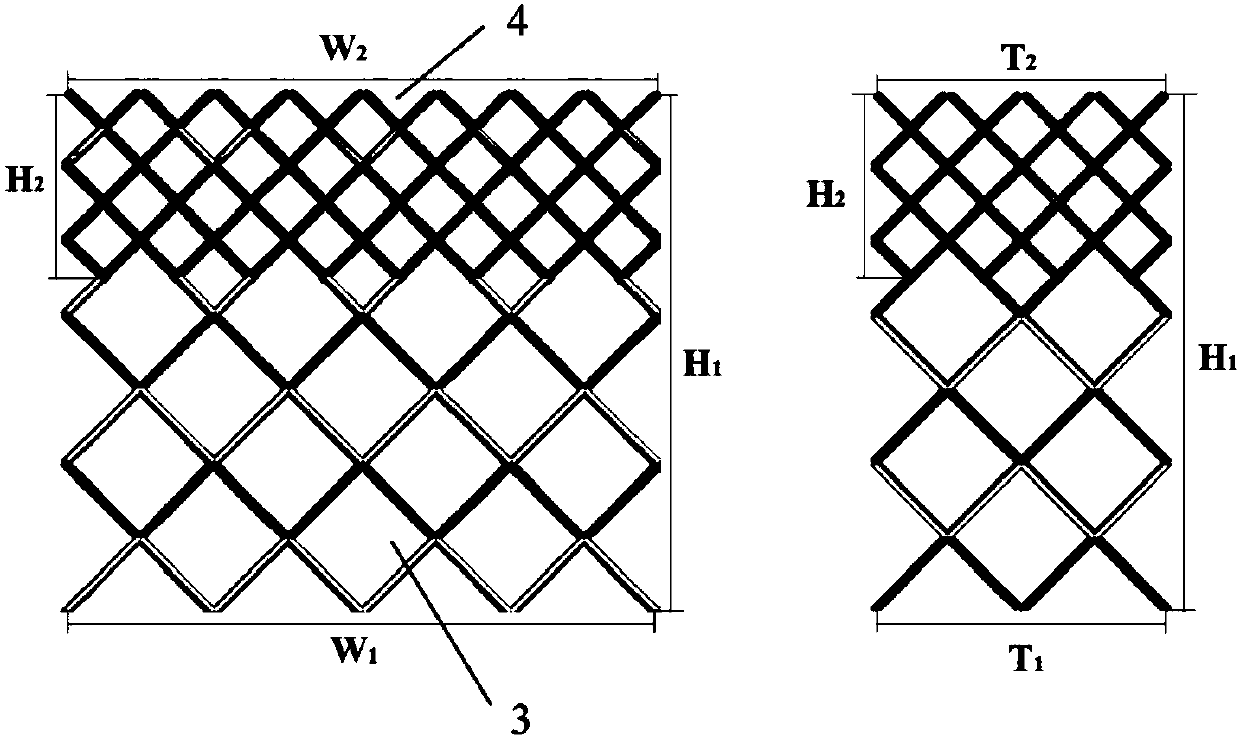

[0025] A lattice sandwich structure of a phase change energy storage device based on additive manufacturing, the lattice sandwich structure is an integrated structure prepared by an additive manufacturing process, the exterior is a shell 5, and the interior is a three-dimensional network structure;

[0026] The effect of described casing 5 is to realize the sealing outside of described lattice sandwich structure, and casing 5 is a cuboid structure, and its width, height, thickness are respectively W=243mm, H=167mm, T=15mm, and casing 5 The wall thickness (that is, the thickness of the AlSi10Mg aluminum alloy plate) t=0.4mm, such as Figure 4 shown;

[0027] The shell 5 is processed with a process hole and a filling hole. The inner diameter of the process hole is φ4.5mm, the outer diameter is 6.5mm and the length is 4.5mm, and the inner diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com