Driving device for particle movement in terminal closed microchannel and cascade control method

A microchannel and particle technology, applied in chemical instruments and methods, transportation and packaging, laboratory containers, etc., to achieve accurate tracking and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

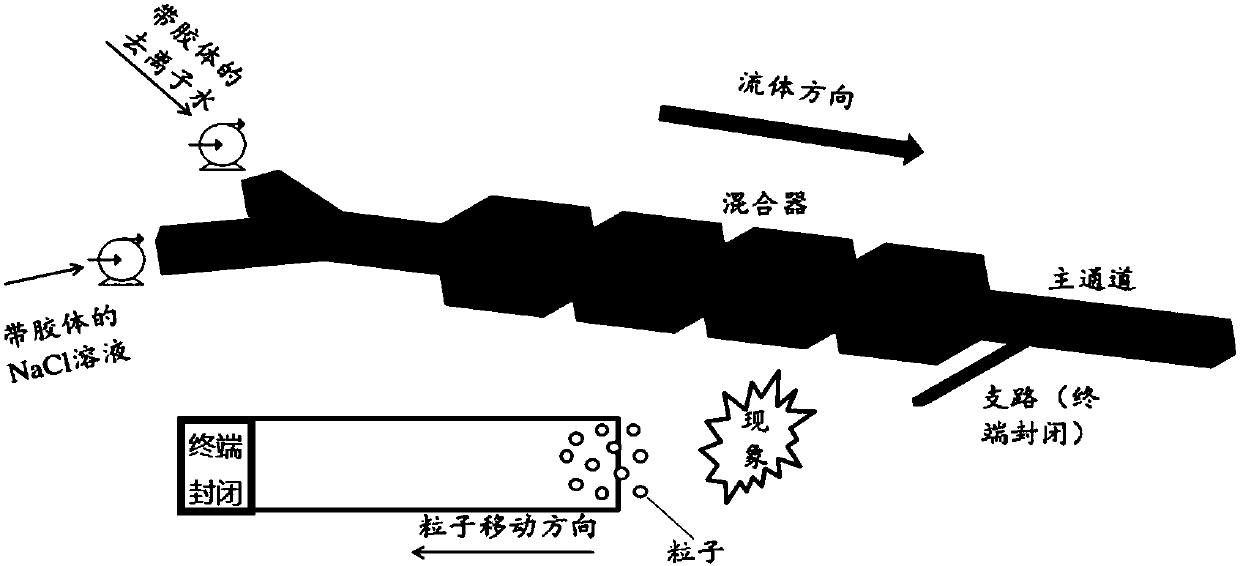

[0045] Such as figure 1 Shown: The topology of the control device for particle movement in a terminally closed microchannel is as follows: a micropump driving NaCl solution with colloid, a micropump driving deionized water with colloid, a mixer and main channel, and a terminally closed Branch microchannel composition.

[0046] The two micropump models are both LSP01-2A, and the flow range that the micropump can control is: 0.0002μl / min-8.6699ml / min. Both NaCl solution and deionized water contained the same particle concentration (1×10 -3 μm -3 ) polystyrene fluorescent particles with a diameter of 1.01 μm, and the concentration of NaCl solution is 2×10 3 μm / L. The mixer, the main channel and the branch microchannels are all rectangular channels. The width and height of the mixer and the main channel are 200 μm×100 μm, and the length, width and height of the branch microchannels are 400 μm×20 μm×10 μm. It can be seen that the scale of the branch microchannel is much small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com