Method for hydrothermal production of magnesium hydroxide nano-film from magnesium oxide

A technology of nano-film and magnesium hydroxide, which is applied in the direction of chemical instruments and methods, nanotechnology, single crystal growth, etc., can solve the problems of restricting industrial production, long reaction time, low investment, etc., and achieve large-scale industrial production and fast The effect of preparation and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

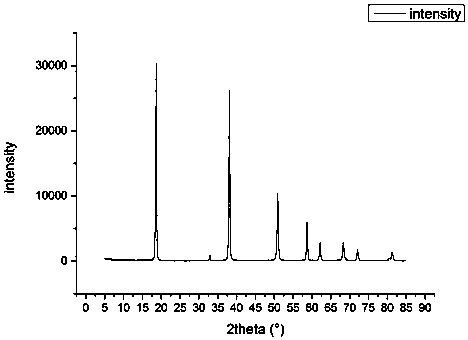

[0025] Take Δn Cl - Put 20 g of activated magnesium oxide at 5 mol / kg into 1500 ml of distilled water to prepare a magnesium oxide suspension, then add 12 ml of 100 wt% ethylene glycol amine solution to the magnesium oxide suspension, and put it into a high-pressure The hydrothermal reaction was carried out in the kettle. The hydrothermal temperature was 140 °C, the hydrothermal time was 3 h, and the stirring speed was 300 r / min. , to obtain a uniformly distributed, high-transparency single-layer magnesium hydroxide nano film. The SEM photos and XRD patterns of the product are as follows figure 1 with figure 2 shown.

Embodiment 2

[0027] Take Δn Cl - Put 20 g of active magnesium oxide of 12 mol / kg into 1500 ml of distilled water to prepare a suspension of magnesium oxide, then add 10 ml of diethanolamine solution with a concentration of 100 wt% to the suspension of magnesium oxide, and put it in an autoclave The hydrothermal reaction was carried out, the hydrothermal temperature was 180 °C, the hydrothermal time was 2 h, and the stirring speed was 200 r / min. After the hydrothermal reaction was completed, suction filtration, washing, filtration, and finally drying at 95 °C for 3 h gave Uniformly distributed, highly transparent single-layer magnesium hydroxide nano film. The SEM photos and XRD patterns of the product are as follows image 3 with Figure 4 shown.

Embodiment 3

[0029] Take Δn Cl - Put 20 g of activated magnesium oxide of 15 mol / kg into 1500 ml of distilled water to prepare a suspension of magnesium oxide, then add 15 ml of triethanolamine solution with a concentration of 100 wt% into the suspension of magnesium oxide, and put it in an autoclave The hydrothermal reaction was carried out, the hydrothermal temperature was 200 °C, the hydrothermal time was 1.5 h, and the stirring speed was 150 r / min. After the hydrothermal reaction was completed, suction filtration, washing, filtration, and finally drying at 95 °C for 3 h were obtained. Uniformly distributed, highly transparent single-layer magnesium hydroxide nano film. The SEM photos and XRD patterns of the product are as follows Figure 5 with Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com