Backfilling method of underground utility tunnel

A technology that integrates pipe gallery and ground, applied in filling, underwater structures, buildings, etc., can solve problems such as affecting traffic safety, affecting road traffic, complicated backfilling construction, etc., achieving good overall performance, preventing floating and moving, and constructing fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

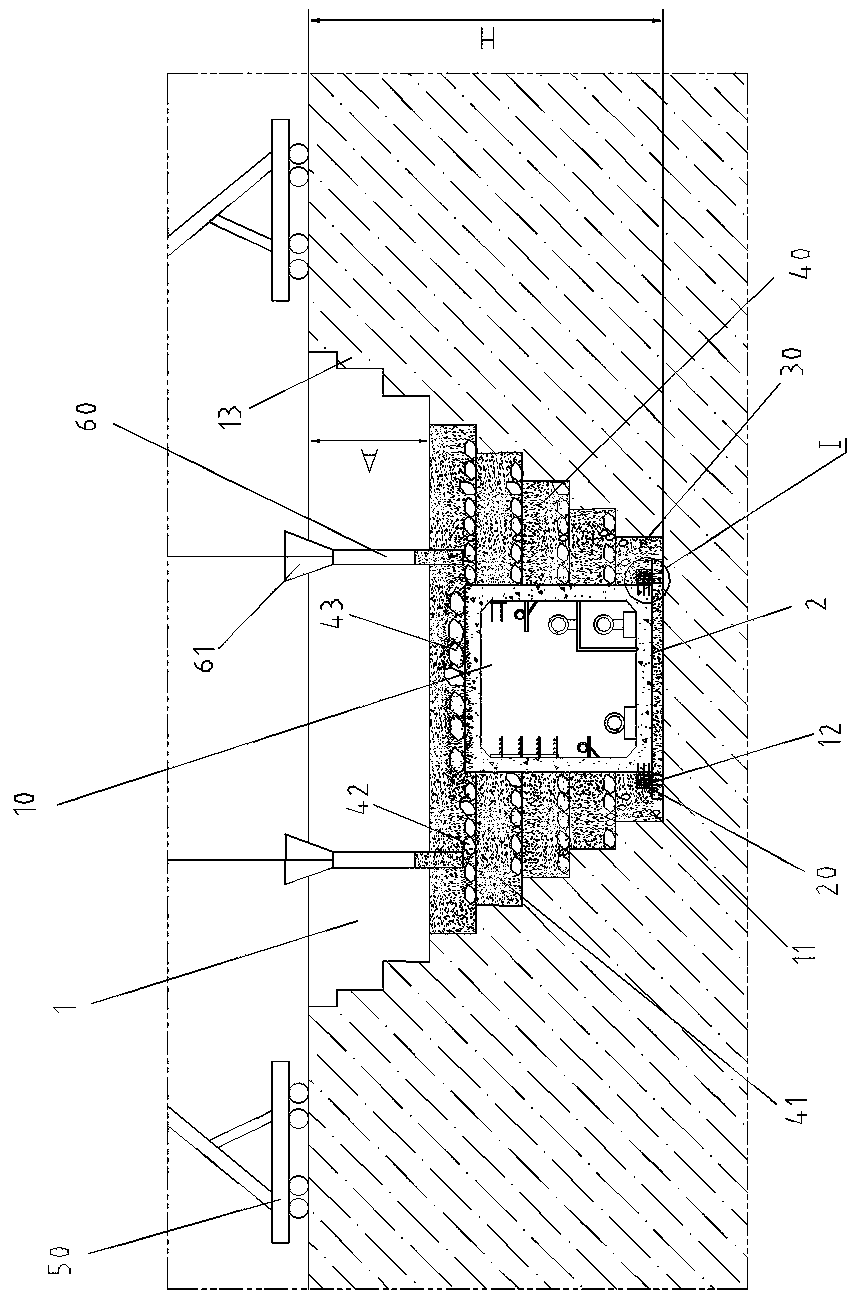

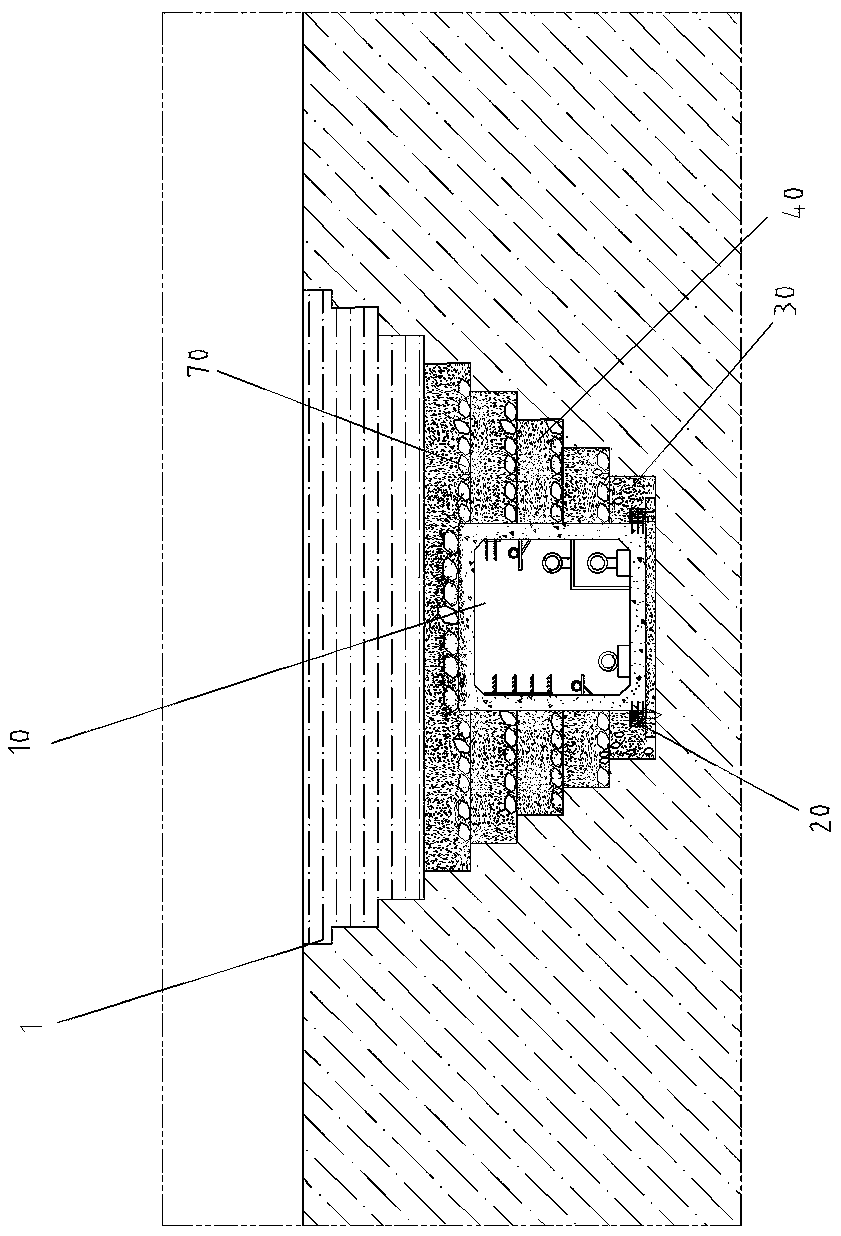

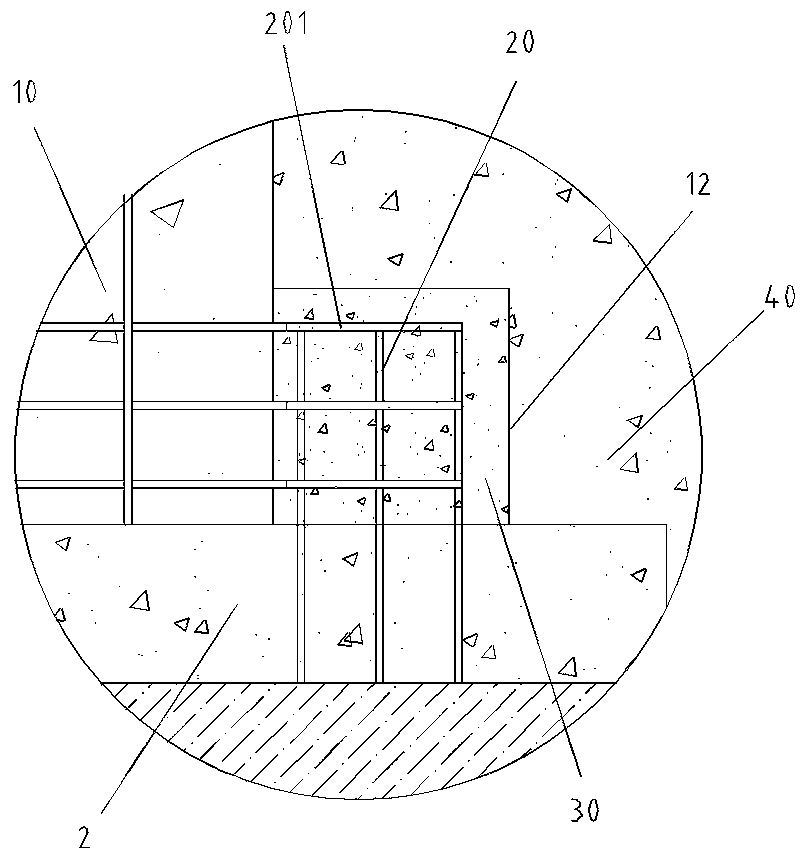

[0029] Such as Figure 1 ~ Figure 3 Shown, the present invention comprises the following steps:

[0030] 1) Preparation before backfilling

[0031] Excavate the double-sided stepped trench 1, the height of each step 13 in the double-sided stepped trench 1 is equal, and the width of each step increases step by step from the ground to the bottom of the double-sided stepped trench 1, forming a large top and a small bottom. Stepped, the double-sided stepped groove 1 of the present embodiment has 7 steps 13 in total, and the connection surface between the multi-level steps 13 and the surrounding soil is in a zigzag shape, which can increase the bonding force between the backfill and the surrounding soil, and improve the bonding strength of the backfill. stability.

[0032] A layer of concrete cushion 2 is poured at the bottom of the excavated double-sided stepped trench 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com