Method for measuring content of cyanate ester monomers

A technology of monomer content and determination method, which is applied in measurement devices, instruments, scientific instruments, etc., to achieve the effects of high precision, avoidance of interference, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

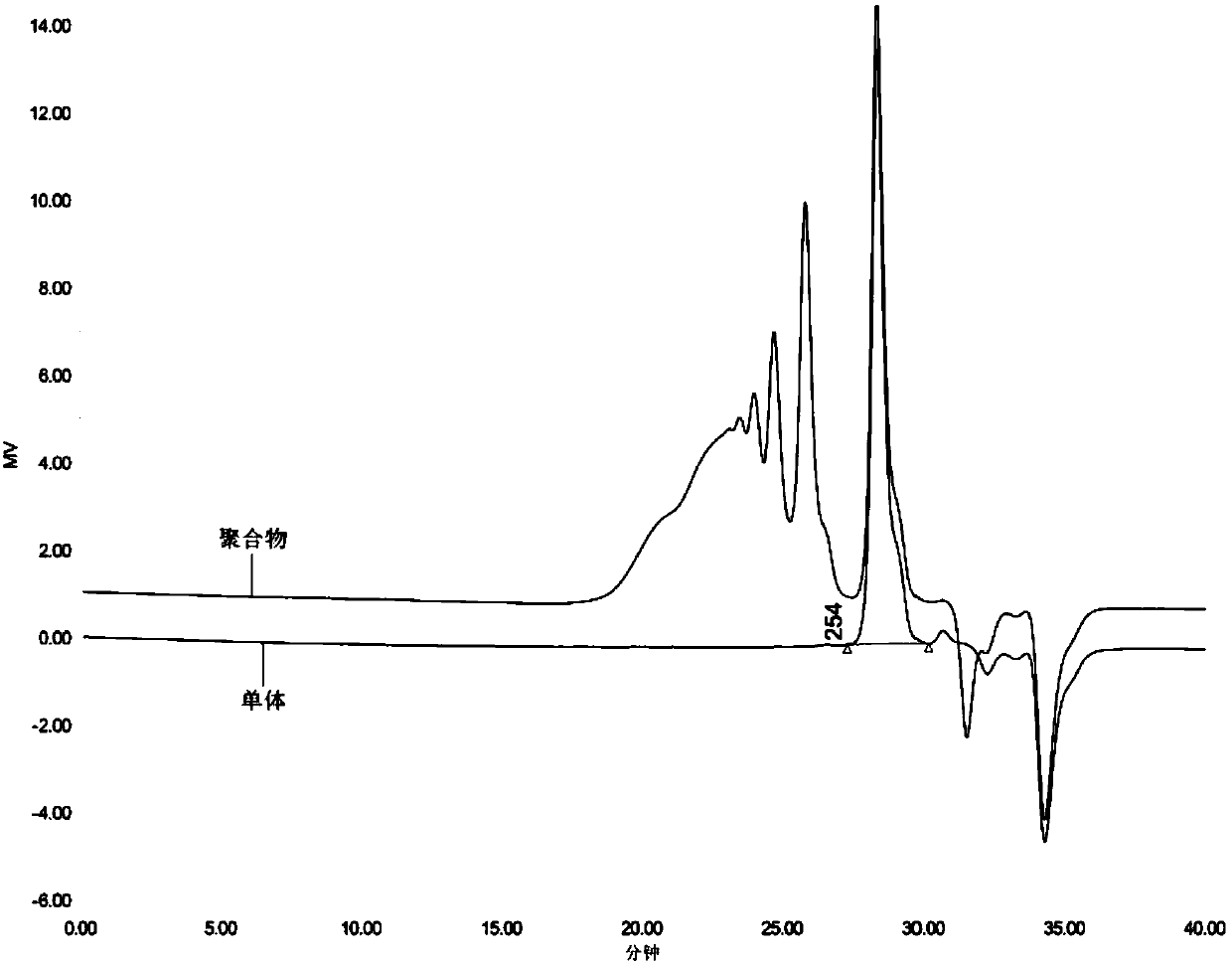

[0027] Embodiment 1 (taking the content measurement of cyanate ester monomer in the bisphenol A type cyanate ester prepolymer as an example)

[0028] 1. Desolventization of bisphenol A cyanate prepolymer

[0029] Spread the bisphenol A cyanate prepolymer thinly on a clean tinfoil paper, and then place it in a vacuum drying oven for drying. The drying temperature can be 20-40°C, and the drying time can be 30-120 minutes. In this embodiment, the drying temperature is set at 30° C., and the drying time is 90 minutes.

[0030] 2. Solvent handling

[0031] The solvent is ultrasonically treated, the temperature of the treatment can be 10-30°C, and the time can be 10-20 minutes. The solvent can be selected from one of toluene and tetrahydrofuran. In this embodiment, the ultrasonic treatment temperature is set at 25°C. The time was 15 minutes and the solvent was tetrahydrofuran (chromatographically pure grade).

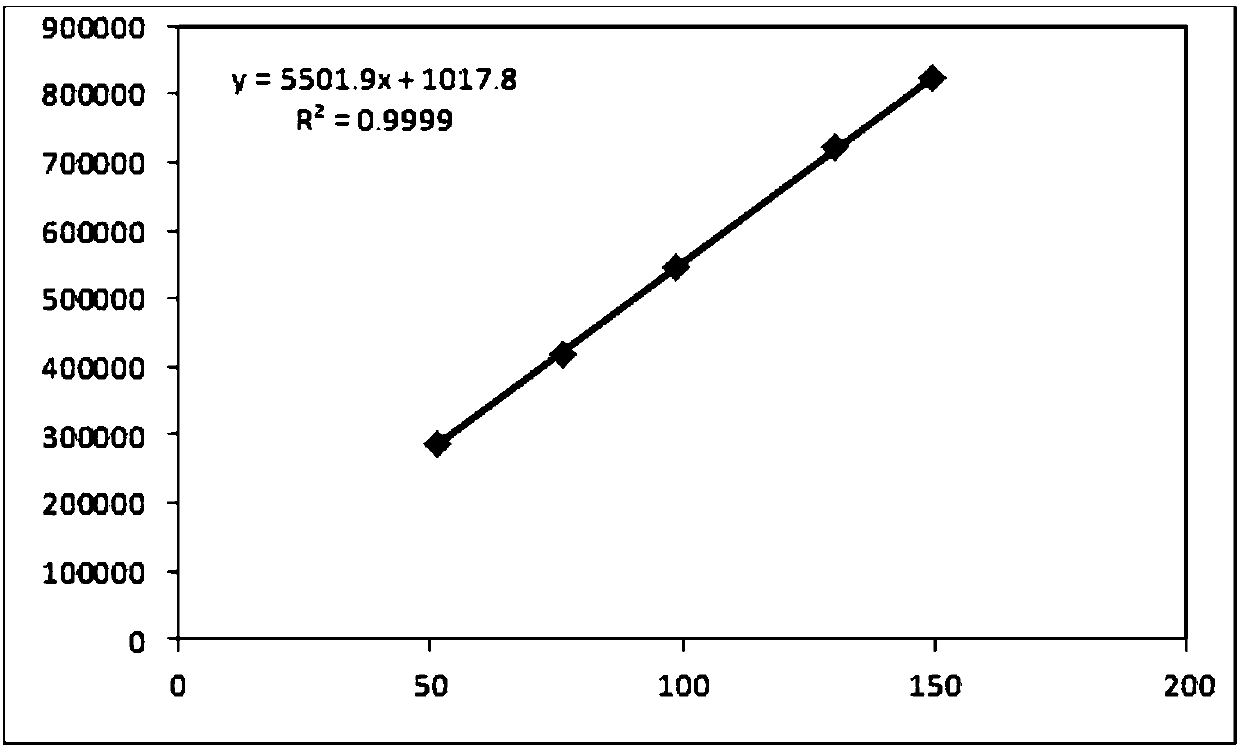

[0032] 3. Make the standard curve of cyanate monomer standard solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com