High pressure damping resistor and manufacturing process thereof

A damping resistor, high-voltage technology, applied in resistors, resistor parts, non-adjustable metal resistors, etc., can solve the problem of poor protection performance of resistance wires or resistance strips, unfavorable high-voltage power system stability, and impact on damping resistors. Service life and other issues, to achieve the effect of ensuring heat dissipation performance, improving convenience, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

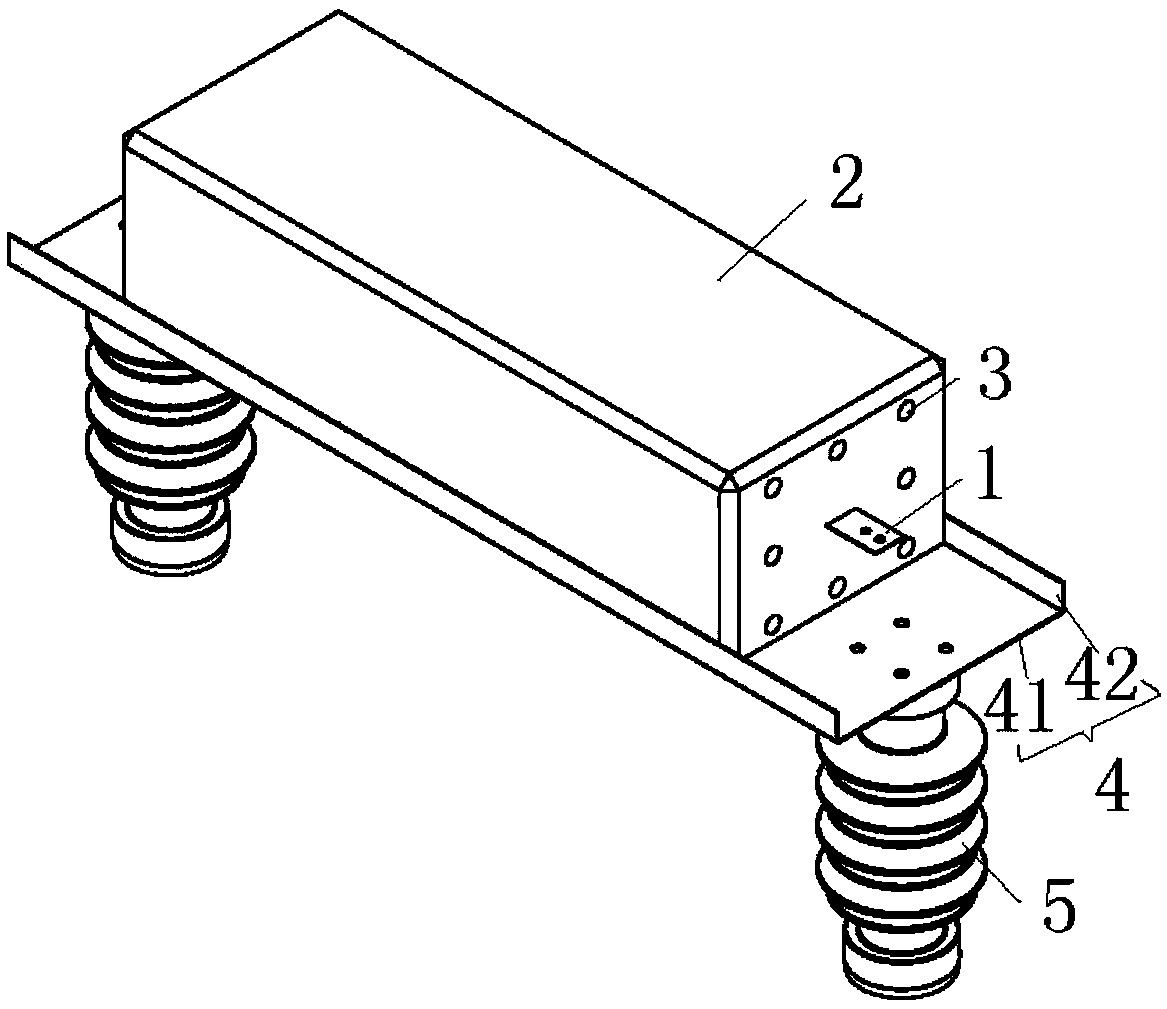

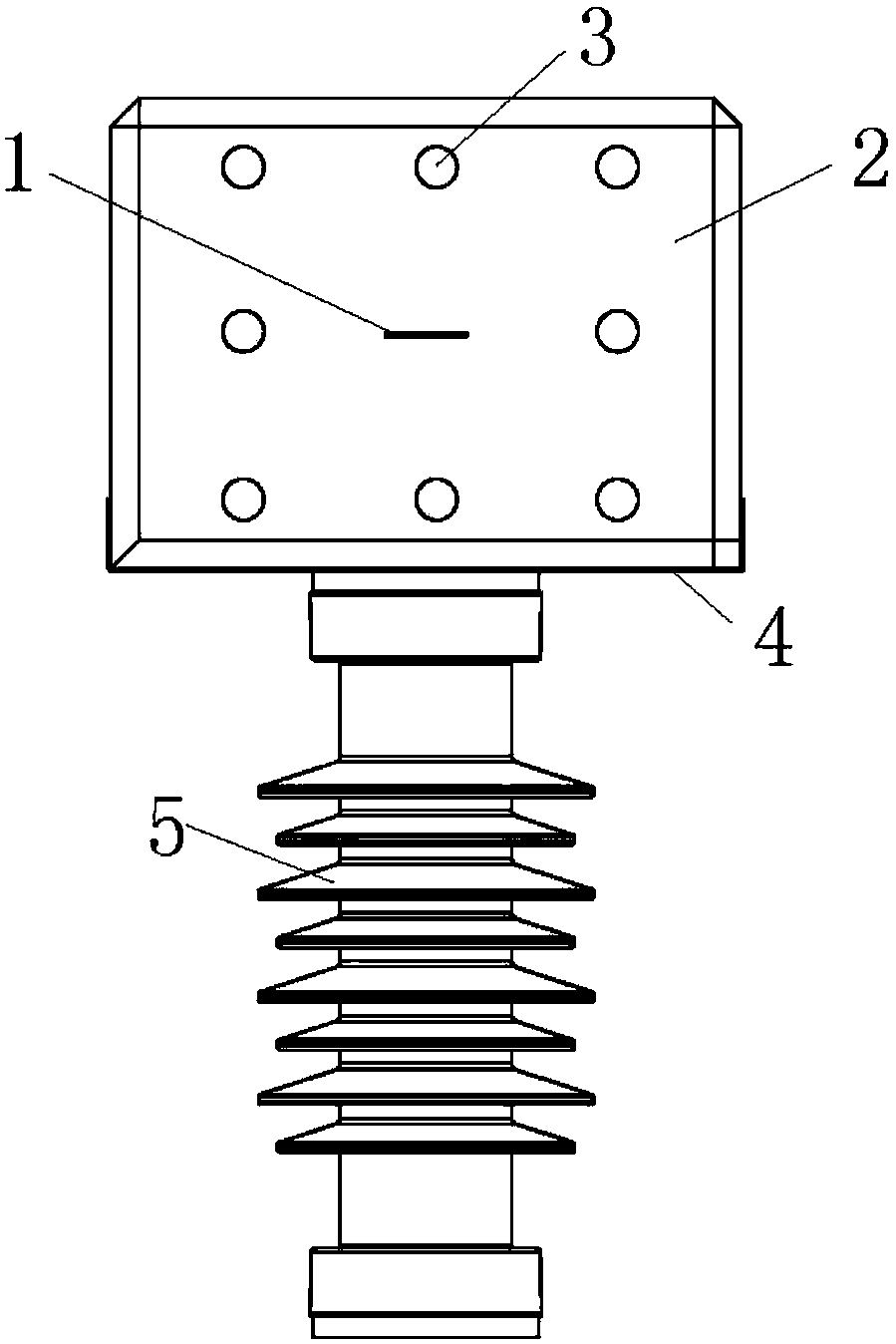

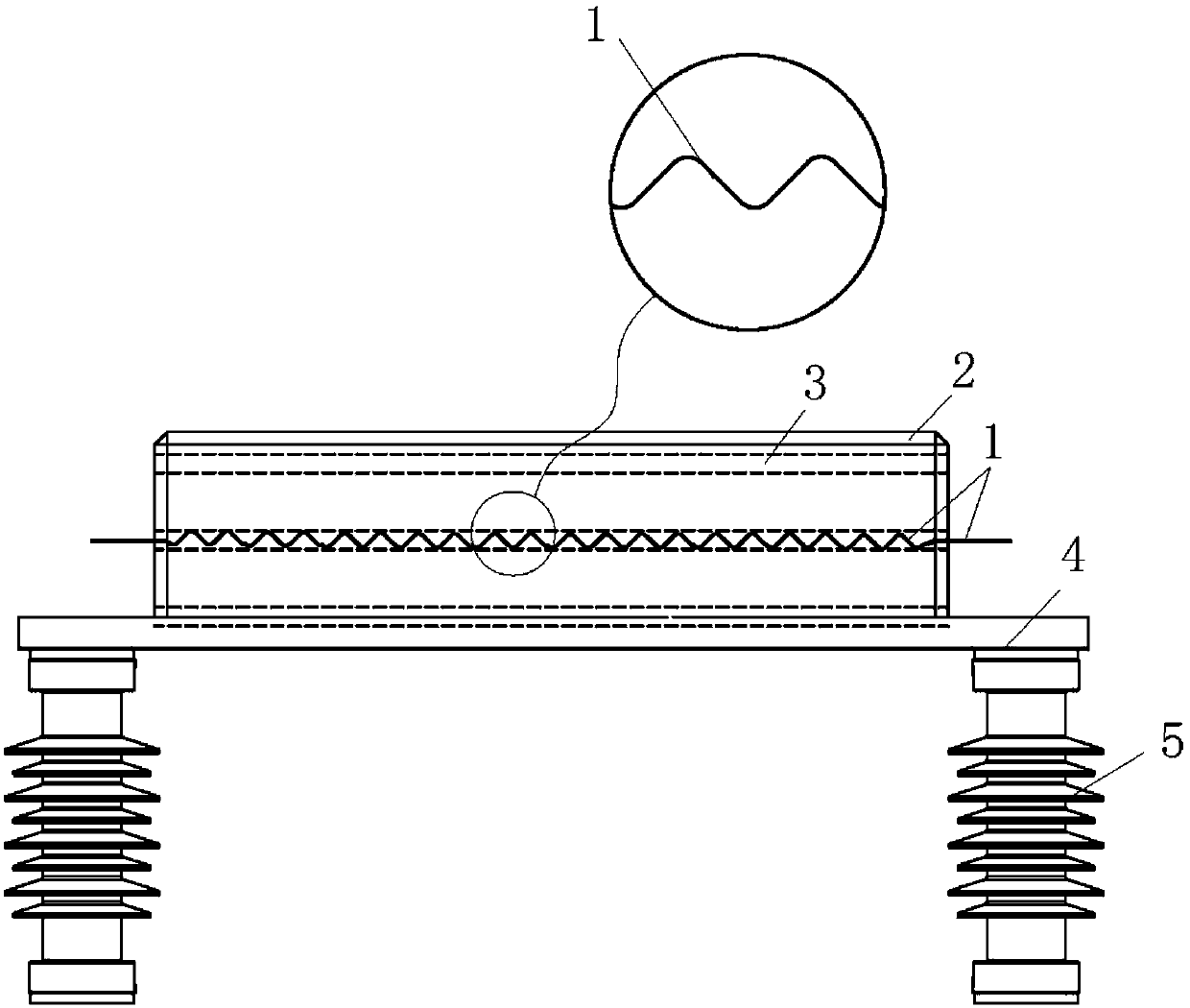

[0028] Such as figure 1 with figure 2 The high-voltage damping resistor shown has a resistance band 1 wrapped in an epoxy resin casting body 2, and the two ends of the resistance band 1 protrude from the epoxy resin casting body 2 so as to connect with the external circuit Connection, of course, the epoxy resin casting body can also be other heat-conducting covering body. Such as image 3 As shown, preferably, the resistance band 1 is a resistance band made of nickel-chromium alloy and is bent into a curved shape in a zigzag manner. The shape can effectively increase the weight and strength of the resistance band. The resistance band 1 can also be a curved surface of other structures, such as a shape-forming surface, that is, as long as it is a curved surface. The epoxy resin pouring body 2 is provided with a heat dissipation pipe 3, and the heat dissipation pipe 3 surrounds the resistance band 1 evenly, and the nozzle of the heat dissipation pipe 3 communicates with the e...

Embodiment 2

[0031] A manufacturing process of a high-voltage damping resistor in this embodiment includes the following steps:

[0032] Step 1. Preheat the vacuum casting tank to 90°C, preheat the mixing container to 76°C, weigh 90 parts of epoxy resin, 45 parts of curing agent, 15 parts of toughening agent and 220 parts of filler, and add appropriate amount Accelerator, then mix the above raw materials evenly and preheat to 46°C, so that the container and raw materials are in a preheated state, preventing the problem of uneven heating or overheating of raw materials during the preparation process;

[0033] Step 2. Pour the preheated raw materials into the mixing container, then heat the mixing container to 65°C and vacuumize it. The raw materials are stirred and degassed in the mixing container for 2 hours to discharge the raw material bubbles;

[0034] Step 3: Place the resistance band and heat dissipation pipe in the damping resistor in the mold used to form the epoxy resin casting bod...

Embodiment 3

[0036] A manufacturing process of a high-voltage damping resistor in this embodiment includes the following steps:

[0037] Step 1. Preheat the vacuum casting tank to 94°C, preheat the mixing container to 80°C, weigh 100 parts of epoxy resin, 55 parts of curing agent, 25 parts of toughening agent and 280 parts of filler, and add appropriate amount Accelerator, then mix the above raw materials evenly and preheat to 50°C, so that the container and raw materials are in a preheated state, and prevent the problem of uneven heating or overheating of raw materials during the preparation process;

[0038] Step 2. Pour the preheated raw materials into the mixing container, then heat the mixing container to 70°C and vacuumize the mixture. Stir and degas the mixture in the mixing container for 2.5 hours to discharge the raw material bubbles;

[0039] Step 3: Place the resistance band and heat dissipation pipe in the damping resistor in the mold used to form the epoxy resin casting body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com