Graphene oxide film-based electric energy generation method

A technology of graphene film and production method, which is applied in chemical instruments and methods, generators that convert kinetic energy into electric energy, inorganic chemistry, etc., can solve the problems of aqueous solution leakage, restricted aqueous solution fluidity, expensive materials, etc., and achieve low cost , to achieve the effect of multi-level utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

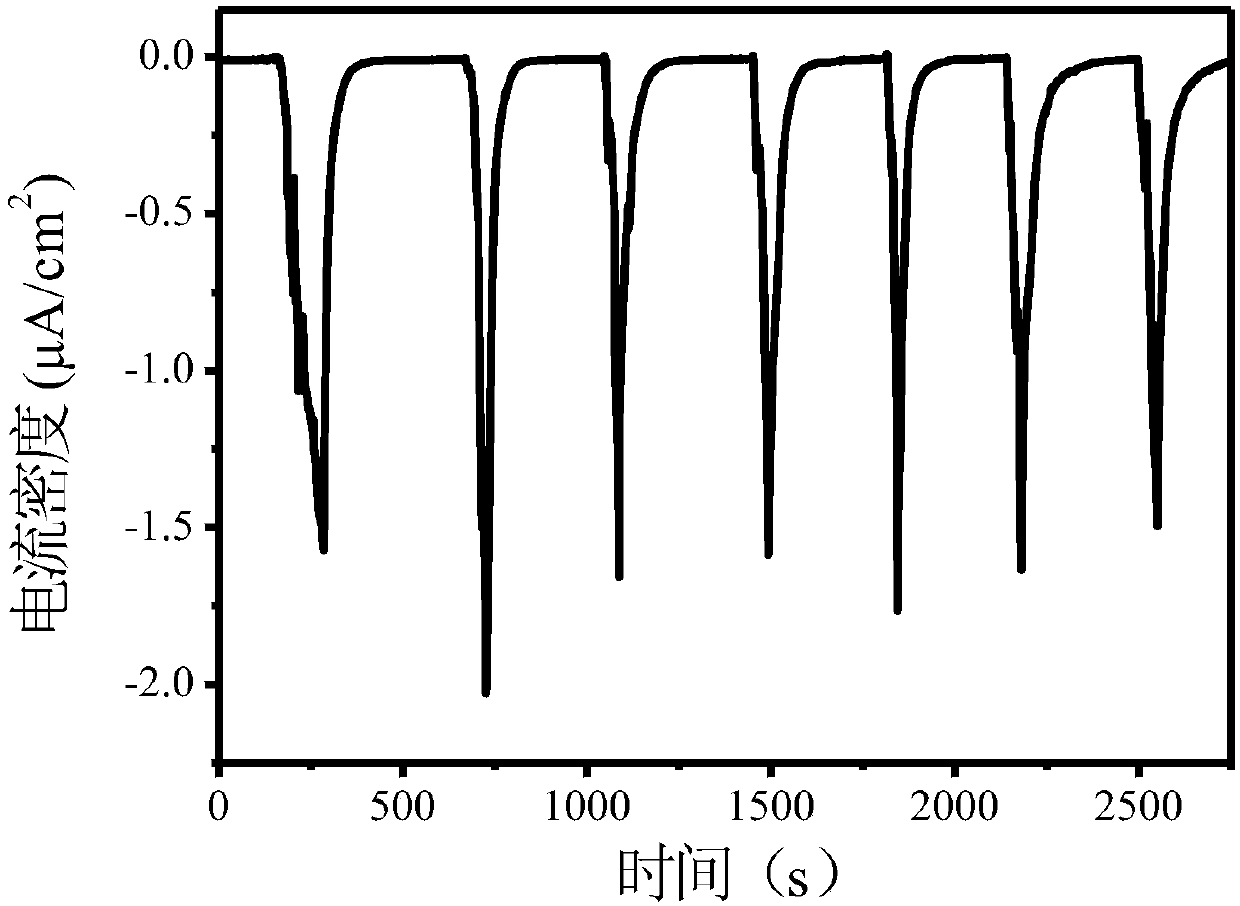

[0034] The test method of embodiment 5 is:

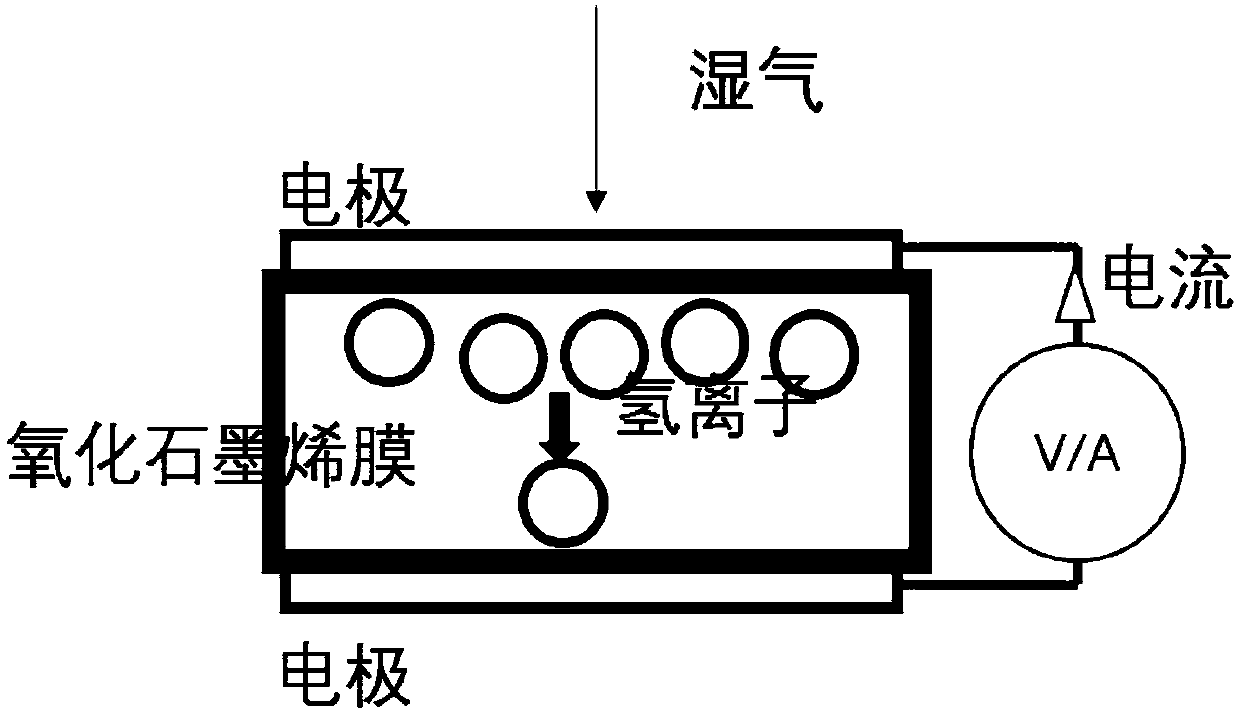

[0035] Place two conductive materials of the same material on both sides of the graphene oxide film, and apply a pressure of 10Mpa to ensure a tight installation. Connect the electrical signal testing instrument to the conductive material with a wire for testing.

[0036] The electrical signal testing instrument used is a Keithley digital source meter (2400). The bias voltage for testing the short-circuit current is about 5 μV, and the current for testing the open-circuit voltage is about 3 pA.

[0037] The preparation method of the graphene oxide film is as follows: after grinding 9g of sodium nitrate in a mortar, mix it with 9g of graphite powder and add it into 240mL of concentrated sulfuric acid. Under the condition of ice bath and stirring, slowly add 40.5g of potassium permanganate into the concentrated sulfuric acid, and continue to vigorously stir for 2h. The system was warmed up to 36 °C and maintained for 2 h. Subsequent...

Embodiment 1

[0039] A method for generating electric energy based on graphene oxide film, the method steps are as follows:

[0040] (1) Place two identical gold sheets (1*2cm) on both sides of the graphene oxide film, and apply a pressure of 10Mpa to ensure fast installation to form a power generation device;

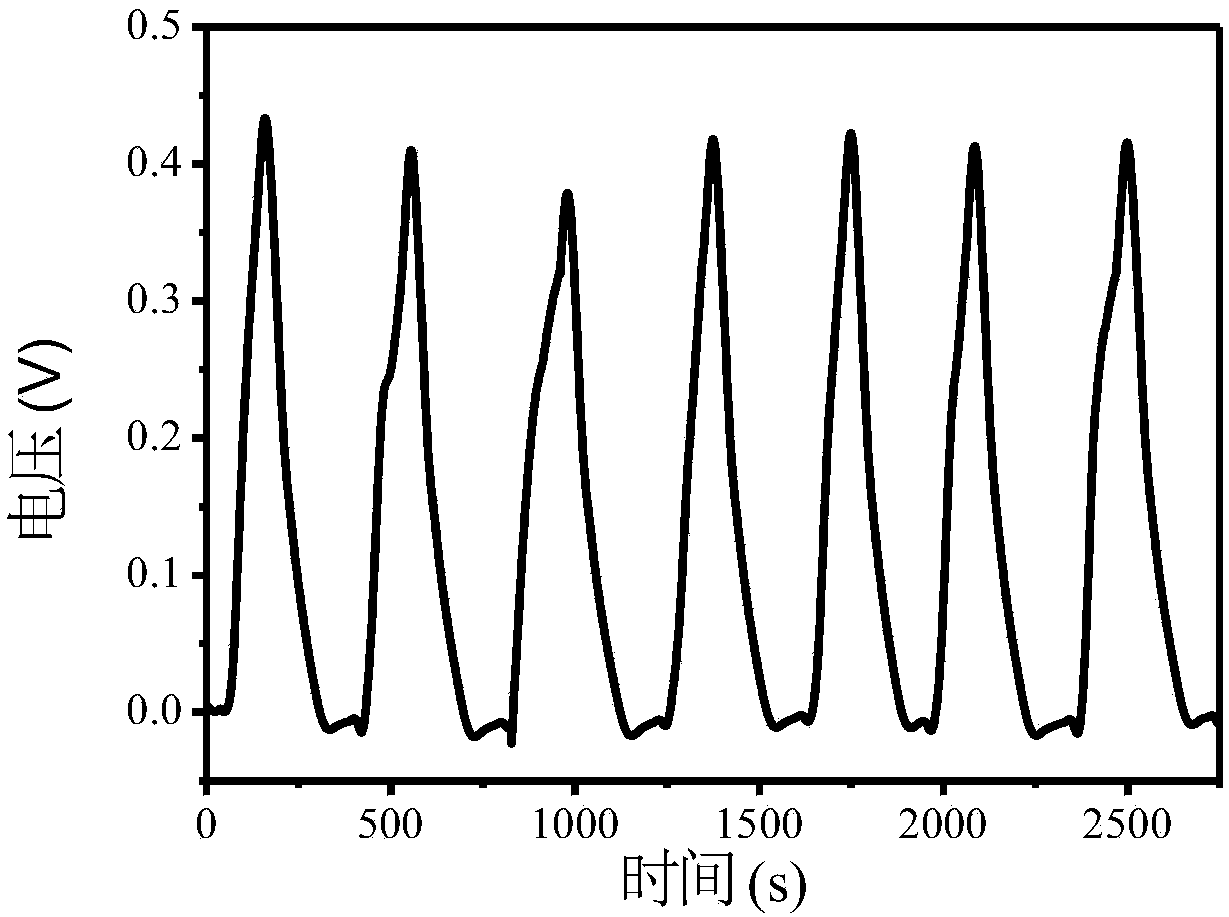

[0041] (2) By intermittently applying moisture to the power generation device and changing the humidity environment of the graphene oxide film, electricity can be generated;

[0042] Wherein, the graphene oxide film is obtained after suction filtration of the graphene oxide aqueous solution, and the moisture is applied at the position where the conductive material contacts the graphene oxide film; the moisture is along a direction perpendicular to the graphene oxide film layer Applying; the moisture is applied for 30 seconds and then stopped, and continued after 100 seconds; the temperature of the moisture is 20° C.; the relative humidity of the moisture is 70%.

[0043] The measur...

Embodiment 2

[0046] A method for generating electric energy based on graphene oxide film, the method steps are as follows:

[0047] (1) Place two identical gold sheets (1*2cm) on both sides of the graphene oxide film, and apply a pressure of 10Mpa to ensure fast installation to form a power generation device;

[0048] (2) By intermittently applying moisture to the power generation device and changing the humidity environment of the graphene oxide film, electricity can be generated;

[0049] Wherein, the graphene oxide film is obtained by drying the graphene oxide aqueous solution at 50° C., and the moisture is applied at the position where the conductive material contacts the graphene oxide film; Applied in the sheet direction; the moisture application was stopped after 30 seconds, and continued after 100 seconds; the temperature of the moisture was 20°C; the relative humidity of the moisture was 70%.

[0050] The measured open-circuit voltage is about 250mV-300mV, indicating that electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com