Oxygen candle grain and preparation method thereof

A technology of powder and oxygen candle, which is applied in the field of low-calorie oxygen candle powder and its preparation, can solve the problems of increasing the complexity of the oxygen production system and the inability to meet the requirements of oxygen candle products, and achieve the reduction of calorific value, the stability of the overall structure, and the formulation reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

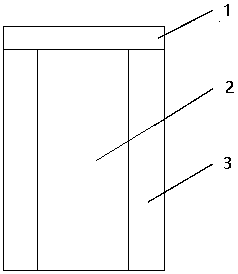

[0028] Embodiment 2 circular powder column

[0029] Flammable medicine 200g, the ratio is sodium chlorate 93%, magnesium powder 3%, cobalt chloride 2%, barium peroxide 2%.

[0030] The inner core drug is 400g, and the ratio is 89% of sodium chlorate, 1.5% of magnesium powder, 0.5% of cobalt chloride, 3% of barium peroxide, and 6% of kaolin.

[0031] Outer ring medicine 400g, the ratio is sodium chlorate 92%, cobalt chloride 4%, barium peroxide 4%.

[0032] After each part of the powder is weighed, use an automatic mixer to dry mix and mix evenly, and then add a certain amount of distilled water to wet mix and mix evenly. The three parts of the powder column are poured into the mold cavity equipped with circular tooling and mechanically pressurized to a density of 2.3g / cm 3 , pressed into powder column. Place it in an oven at 120°C for 14 hours and then cool to room temperature before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com