Bifunctional polyester resin for powder coating and preparation method of polyester resin

A powder coating and polyester resin technology, applied in the field of polyester resin, can solve the problems of unsuitable powder coating, difficult control, complicated process, etc., achieve outstanding comprehensive performance of coating film, diverse polyester resin structure, and huge market application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

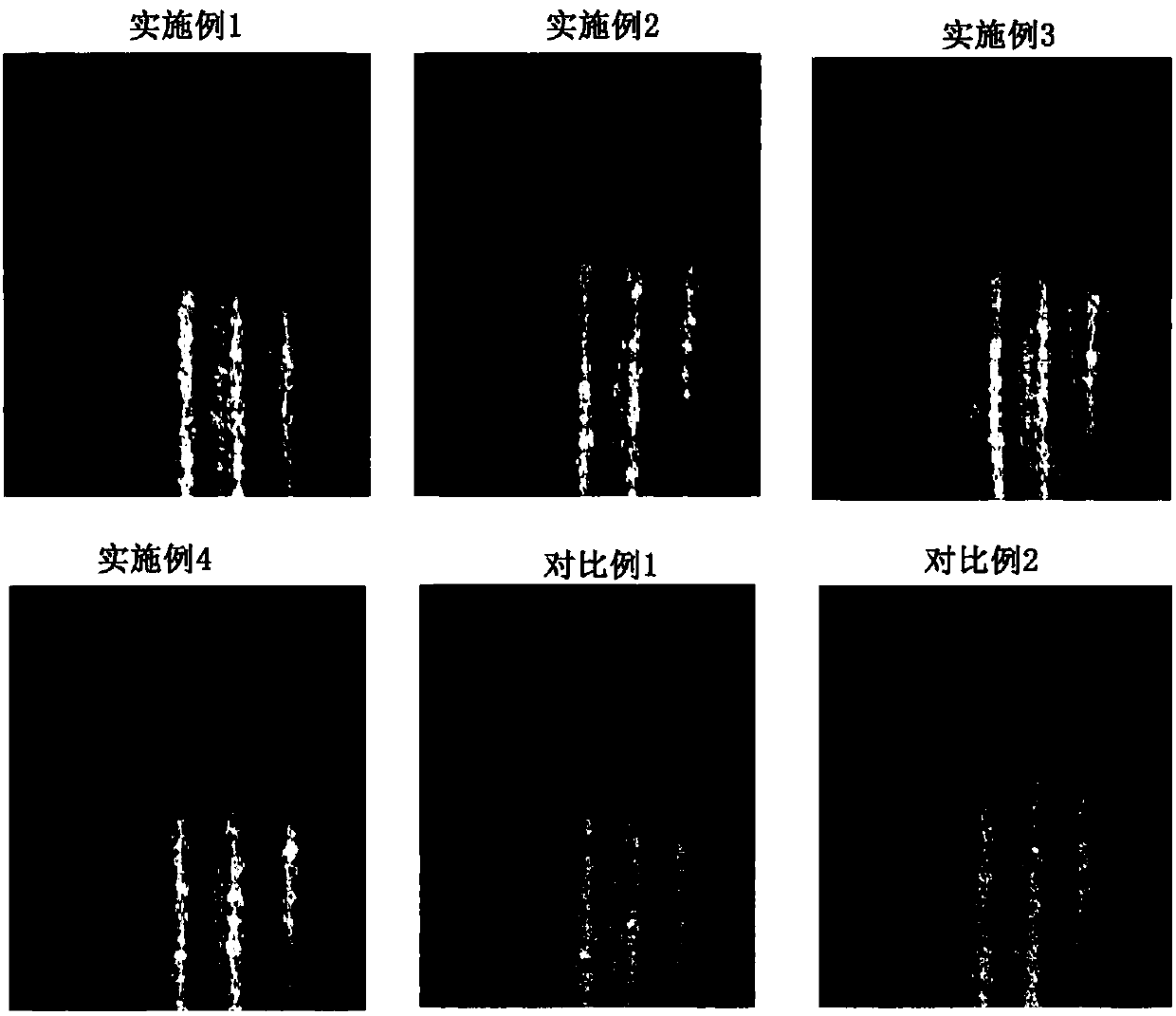

Image

Examples

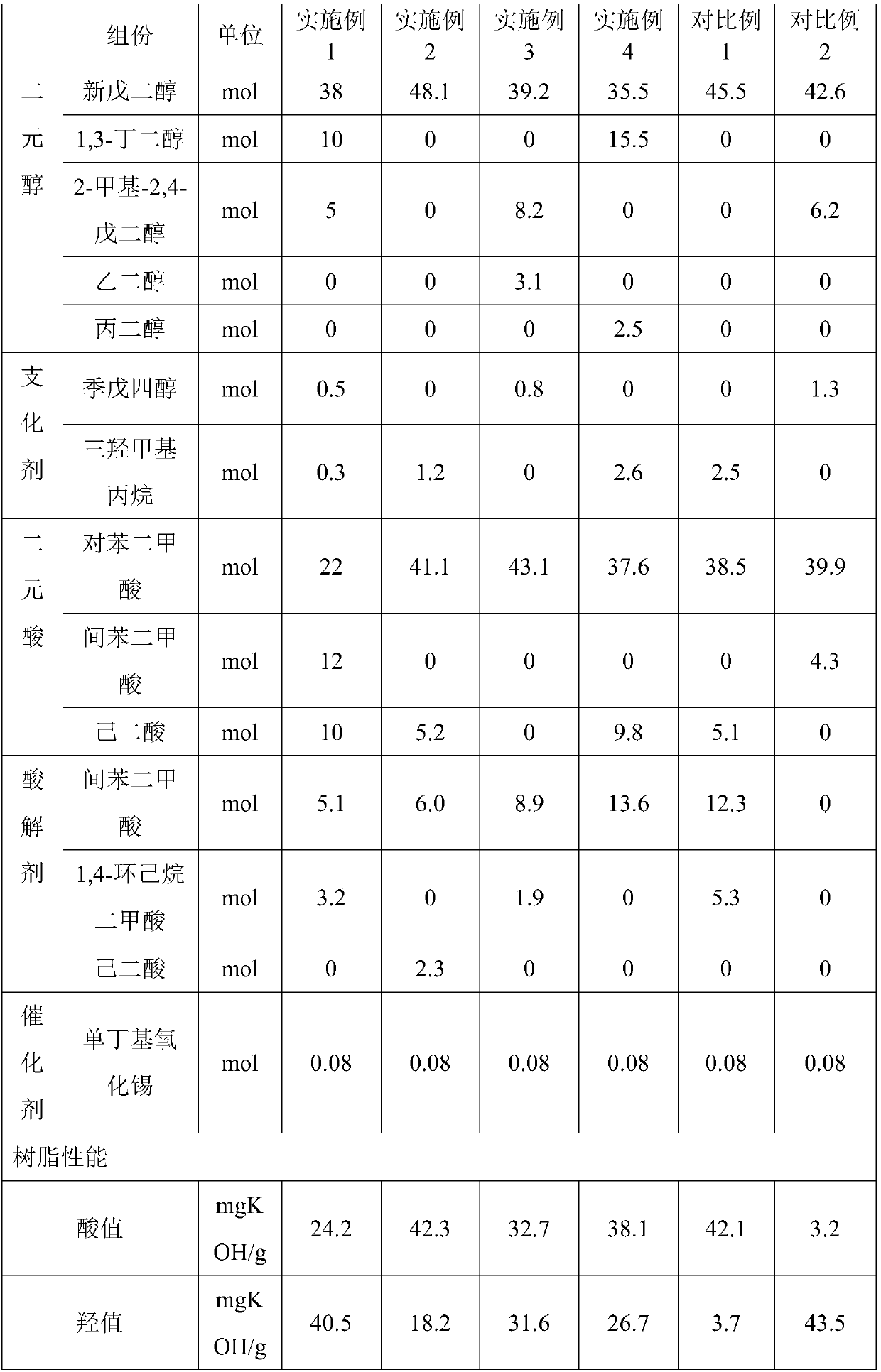

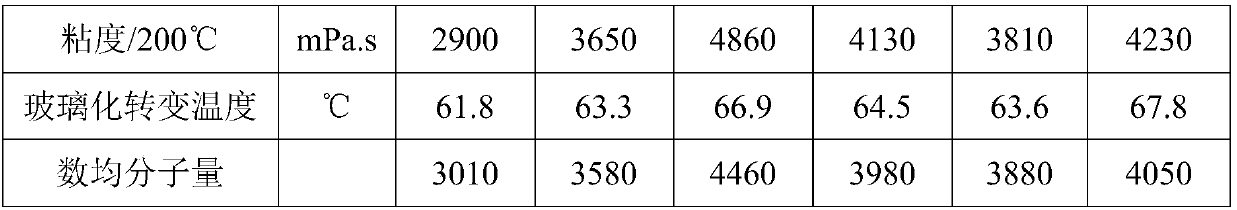

Embodiment 1~4

[0030] Embodiment 1~4 preparation method is as follows:

[0031] (1) Take the proportioned amount of glycol and branching agent, heat up to the material melts, then add the proportioned amount of dibasic acid and esterification catalyst, and continue to heat up the reaction with nitrogen gas, until 175 ° C ~ 180 ° C for esterification Water begins to be formed and distilled out; then after 8-11 hours, the temperature is gradually raised to 237°C-249°C, and kept at this temperature for 2-6 hours until the material system is clear and transparent;

[0032] (2) Cool down to 200°C-210°C, and vacuumize for 3-5 hours. At this time, the acid value of the material reaches below 15mgKOH / g, and the hydroxyl value is 55-95mgKOH / g;

[0033] (3) Raise the temperature to 228°C-236°C, add a proportioned amount of acidolysis agent, and react for 3-5 hours until the material system is clear and transparent, the acid value reaches 30-55mgKOH / g, and the hydroxyl value is 25-55mgKOH / g;

[0034] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com